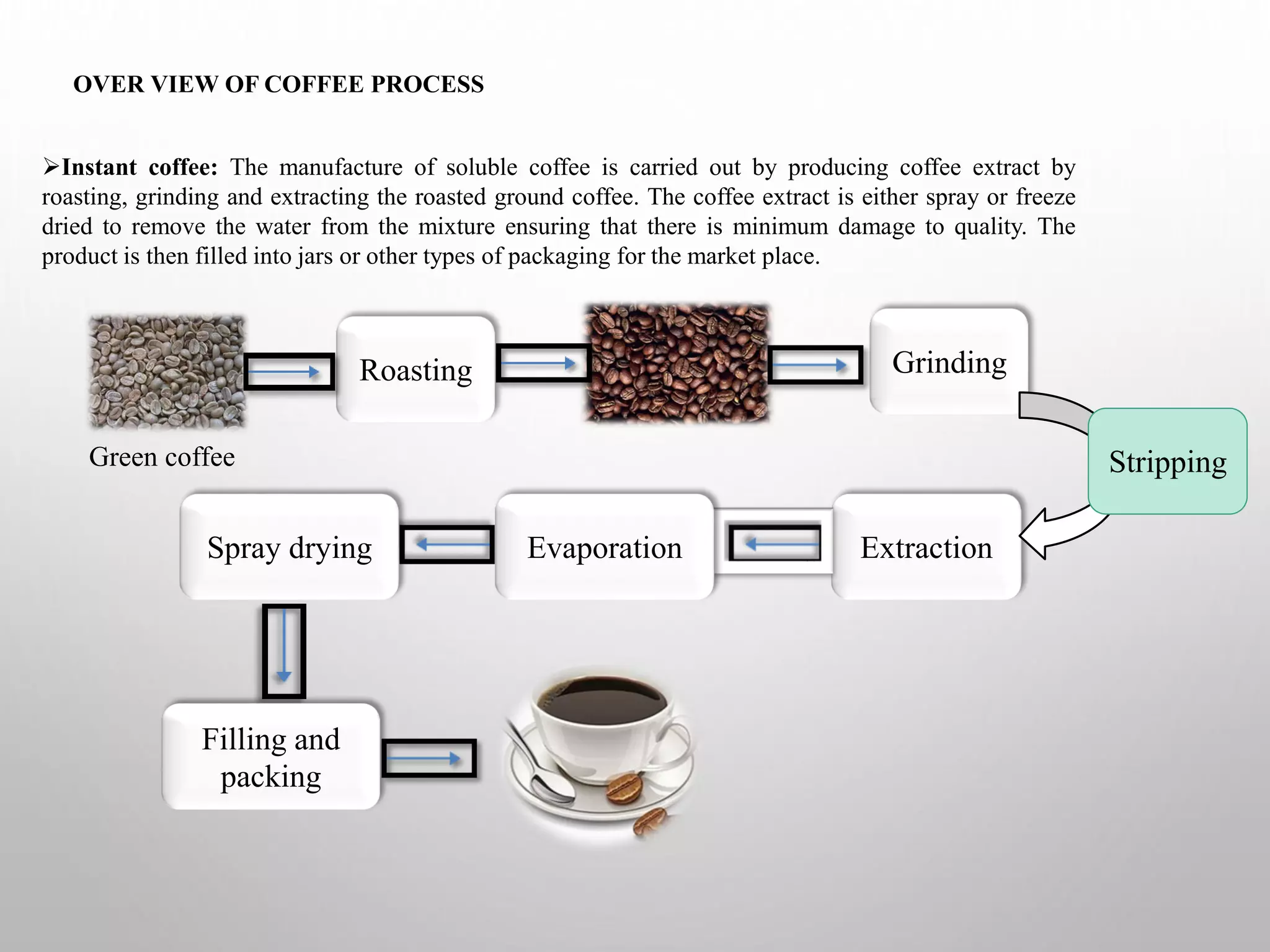

Coffee has been consumed for centuries and originated in Ethiopia. It is a popular beverage worldwide due to its flavor and the stimulating effects of caffeine. There are different varieties of coffee plants with Arabica and Robusta being the most common. The production process involves harvesting coffee cherries, processing them, drying, roasting, grinding, extracting caffeine and flavors, drying the extract, packaging, and distribution. Each step impacts the final quality and taste of the coffee beverage.