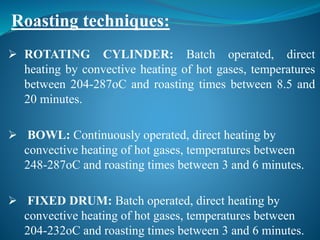

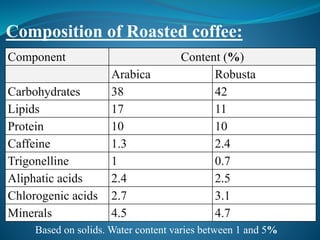

This document provides an overview of a seminar on physico-chemical changes during the roasting of coffee beans. It includes sections on coffee plant selection and harvesting, processing methods, roasting techniques, and changes that occur during roasting. Many physical and chemical reactions take place as the beans are heated, including breakdown of carbohydrates, Maillard reactions, and changes to proteins, lipids, and acids. The composition of roasted coffee includes carbohydrates, lipids, proteins, caffeine, and other components. Decaffeination methods are also summarized.