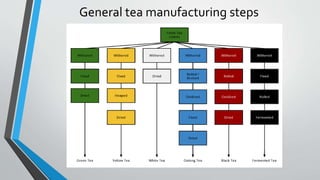

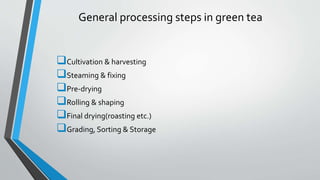

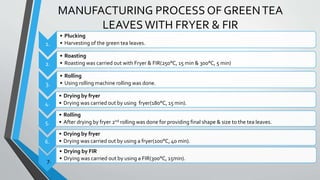

The document describes several processes for manufacturing green tea. In general, the key steps are:

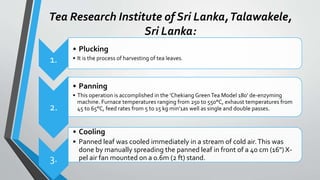

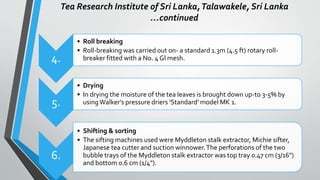

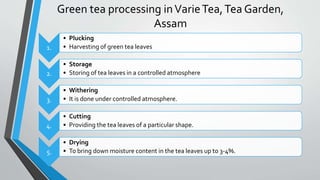

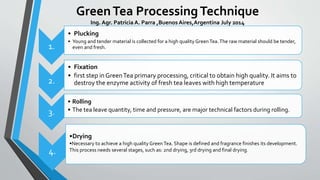

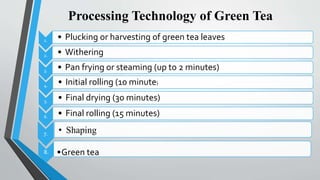

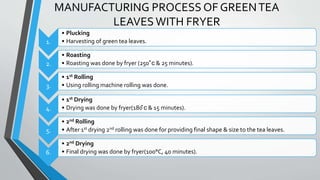

1) Plucking or harvesting of young green tea leaves.

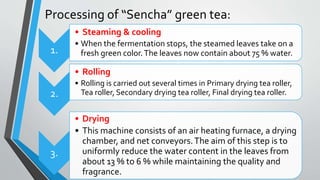

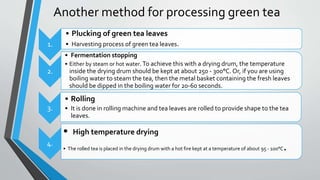

2) Fixing enzyme activity through steaming or pan firing.

3) Rolling leaves to shape them.

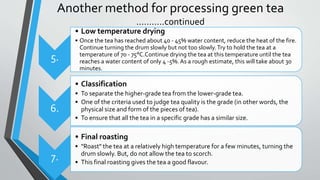

4) Drying leaves through multiple stages to reduce moisture content to around 3-5%.

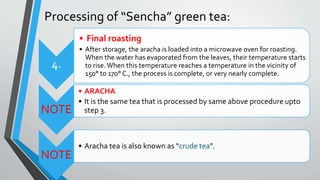

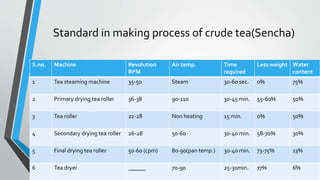

Specific processes may incorporate additional steps like withering, cutting, sorting, and final roasting. Methods can involve different machines, temperatures, times and numbers of rolling and drying stages to produce different types of green tea.