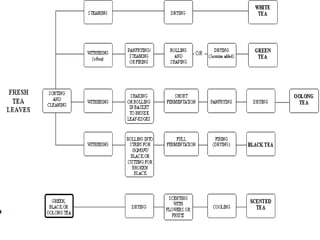

1. Tea processing involves several steps including plucking, withering, rolling, fermentation, drying, sorting, and packing.

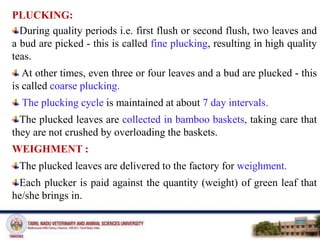

2. During plucking, two leaves and a bud are picked by hand for high quality teas during quality periods.

3. The plucked leaves undergo withering to reduce moisture content before rolling bruises the cells and exposes the sap.

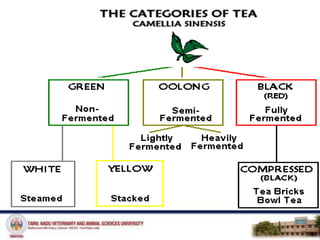

4. Fermentation allows the rolled leaves to oxidize and change color before drying halts the process.