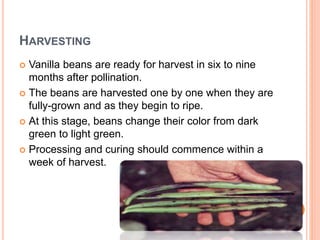

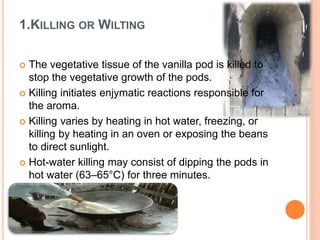

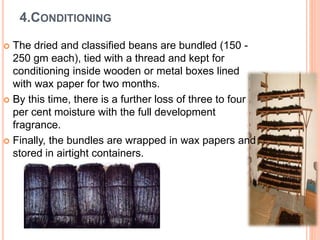

Vanilla beans originate from Mexico and are ready for harvest 6-9 months after pollination. The curing process consists of 4 steps: 1) killing or wilting, 2) sweating, 3) slow-drying, and 4) conditioning. Killing stops vegetative growth while sweating develops flavor and aroma over 7-10 days. Slow-drying further reduces moisture content while conditioning stores bundled beans to fully develop fragrance over 2 months. Vanilla is widely used as a flavoring in foods, beverages, ice cream, coffee, chocolate, and perfumes due to its flavor compound vanillin.