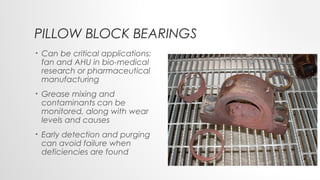

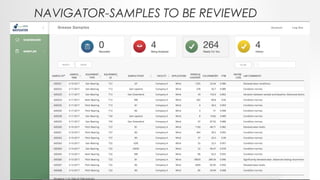

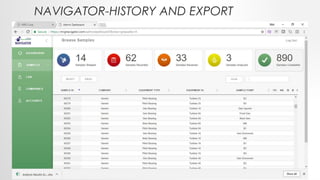

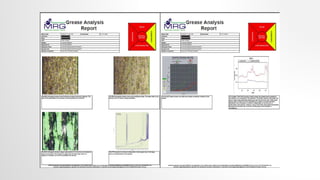

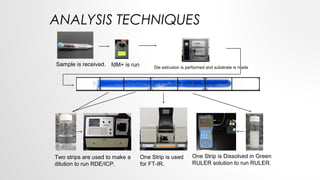

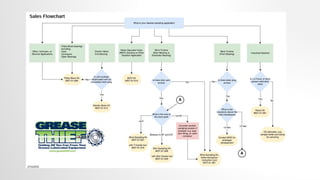

The document discusses advanced grease sampling methods, their challenges, and the importance of analyzing grease in various industrial applications, such as wind turbines and robotics. It outlines standards like ASTM D7718 and provides examples of how proper sampling techniques can lead to effective maintenance and early detection of lubrication issues. Additionally, it emphasizes the value of grease analysis in preventing failures and optimizing lubrication programs by identifying contaminants and ensuring grease quality.