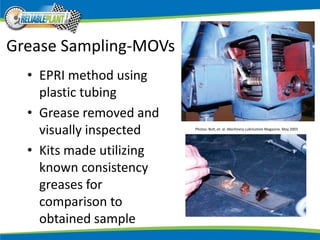

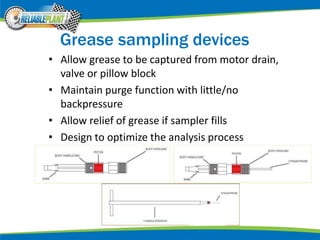

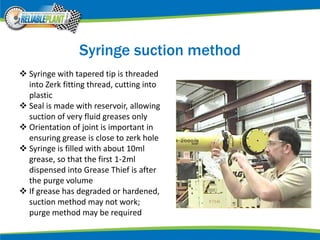

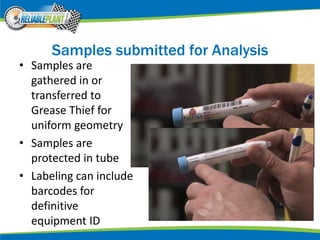

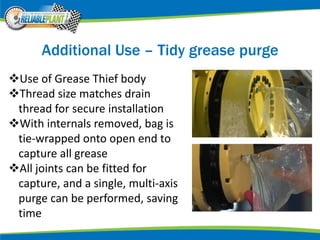

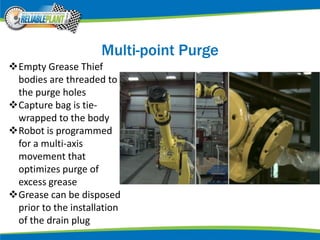

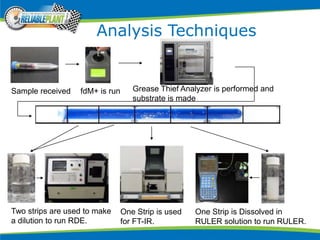

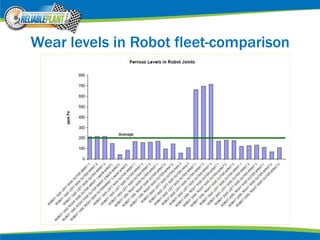

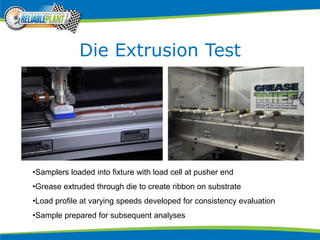

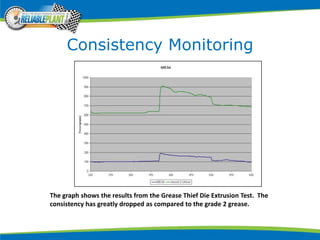

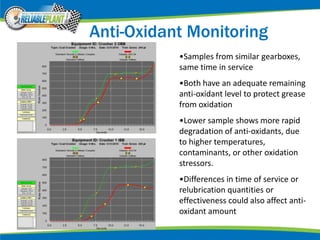

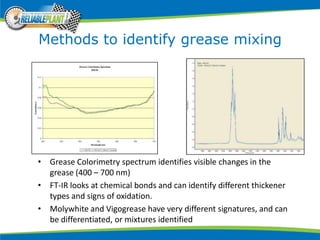

The document outlines the importance of grease sampling and analysis for robotic gear drives, particularly in manufacturing and automotive applications. It discusses methods for sampling grease, the development of a device called the grease thief for efficient sampling without disassembly, and the analysis techniques used to evaluate grease condition and predict potential failures. The document emphasizes the need for condition-based maintenance to optimize grease changeouts and identifies issues related to grease mixing and degradation.