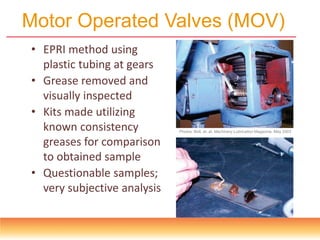

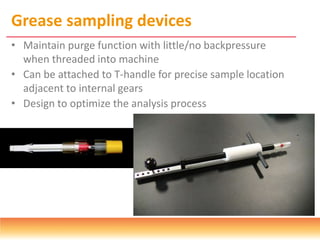

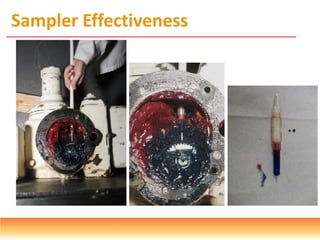

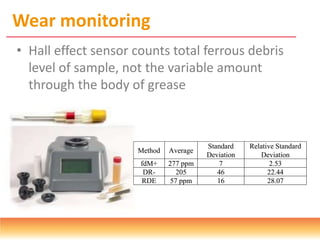

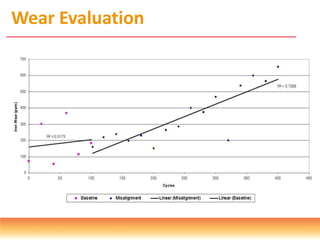

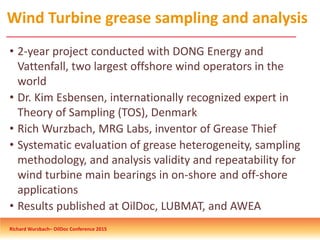

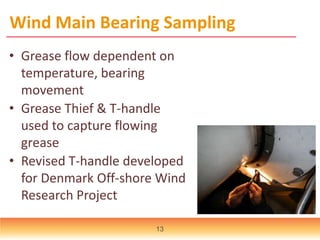

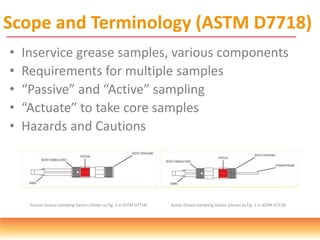

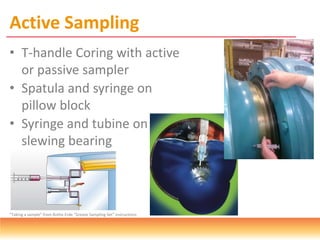

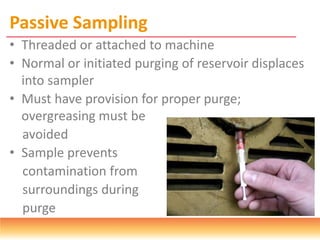

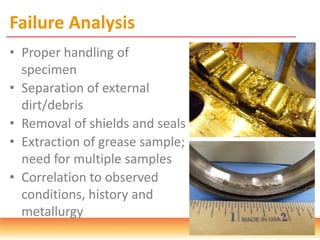

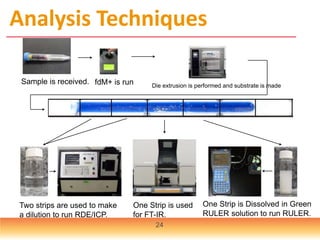

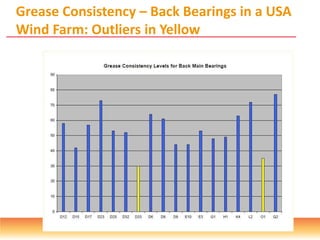

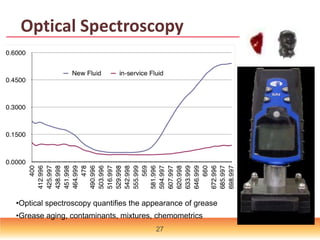

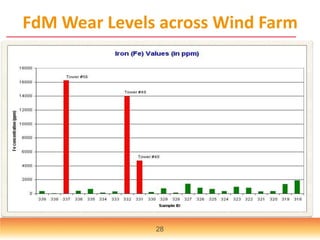

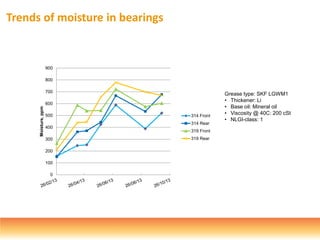

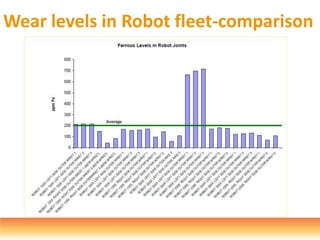

The document discusses various methods and standards for grease sampling and analysis, particularly in wind turbine applications. It emphasizes the importance of sample location, methodologies for effective sampling, and the development of ASTM standards for grease sampling. Projects conducted in collaboration with major offshore wind operators highlight the need for accurate sampling techniques and the consideration of new technologies in grease analysis.