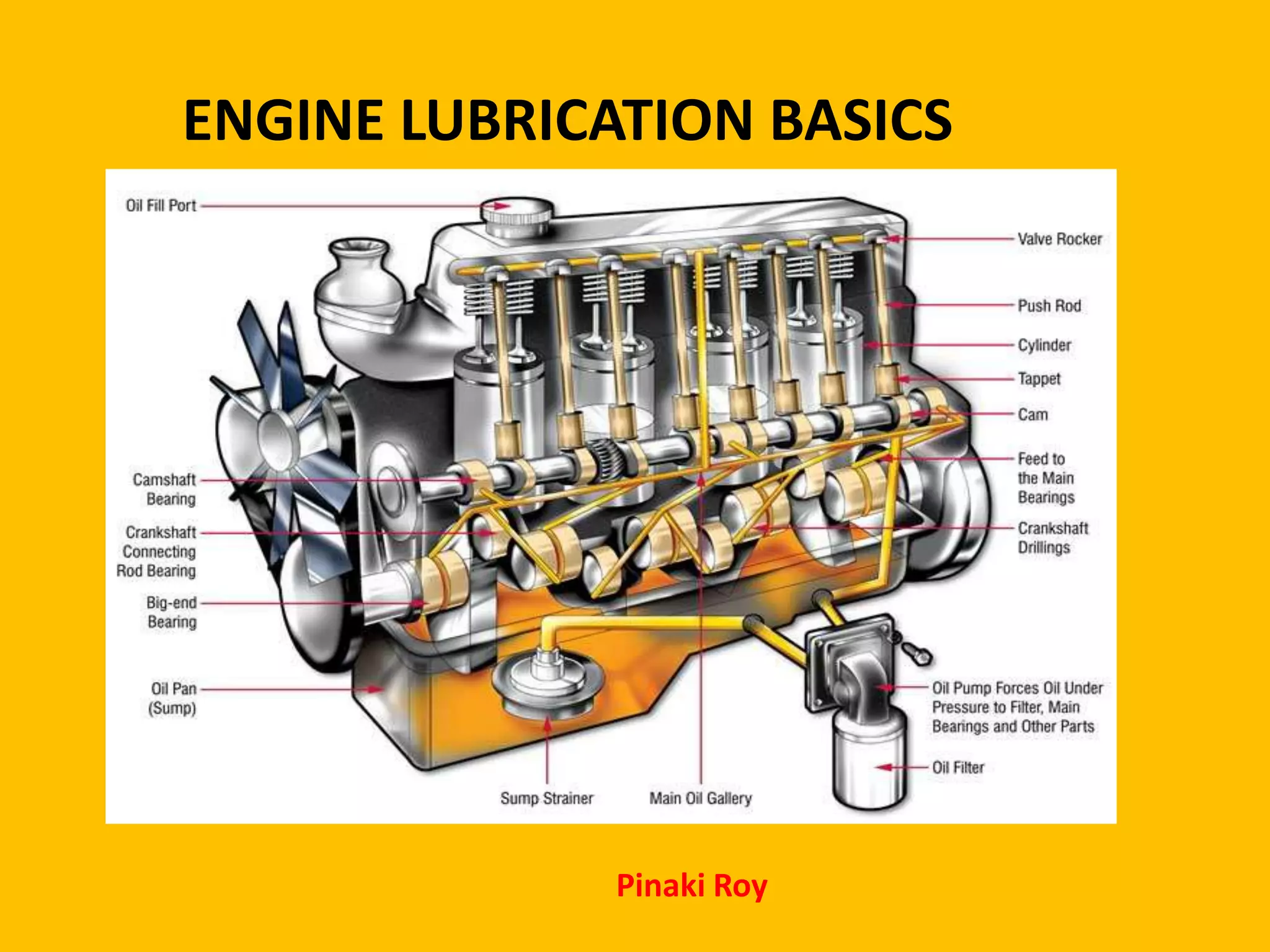

Engine lubrication begins with oil pulled from the sump through a filter, then distributed throughout the engine via passageways to components like bearings and pistons. Lubricants contain additives like detergents that suspend harmful deposits in the oil to prevent damage. A multi-grade oil uses viscosity index improvers that allow it to flow easily at cold temperatures but maintain thickness at higher engine temperatures. Regular maintenance like oil changes is necessary to prevent additive depletion and lubrication breakdown from contamination, overheating, or long drain intervals.