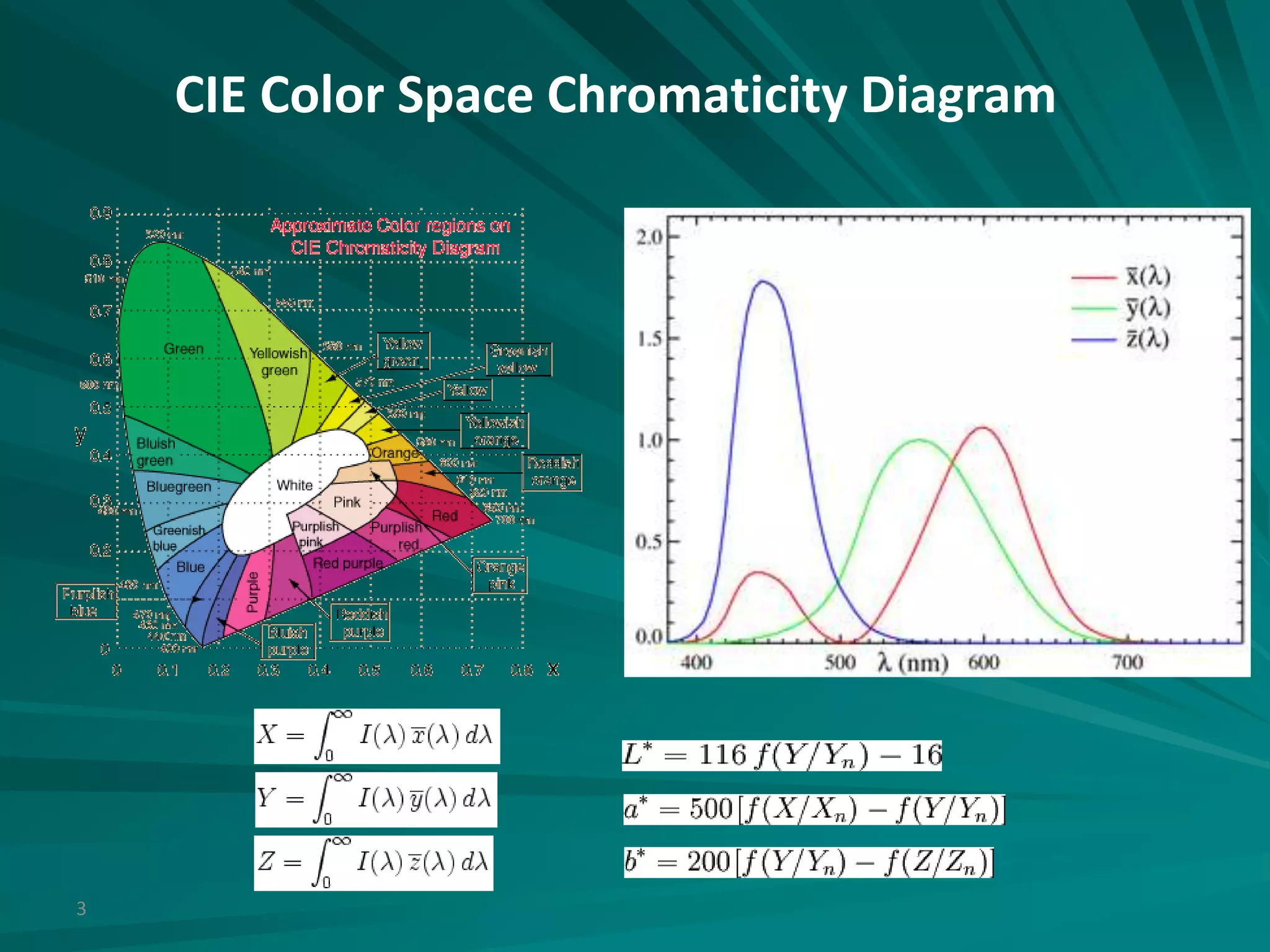

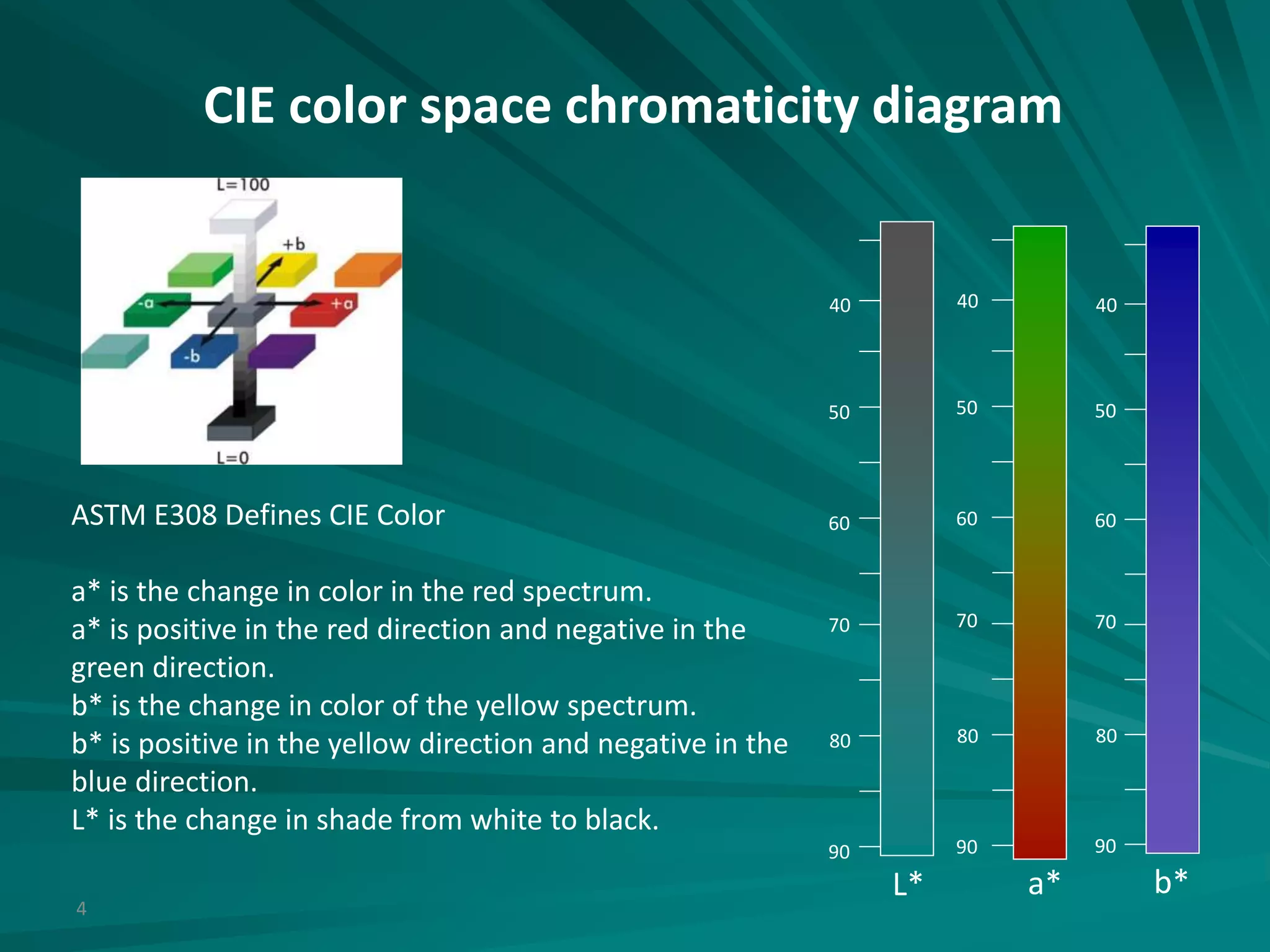

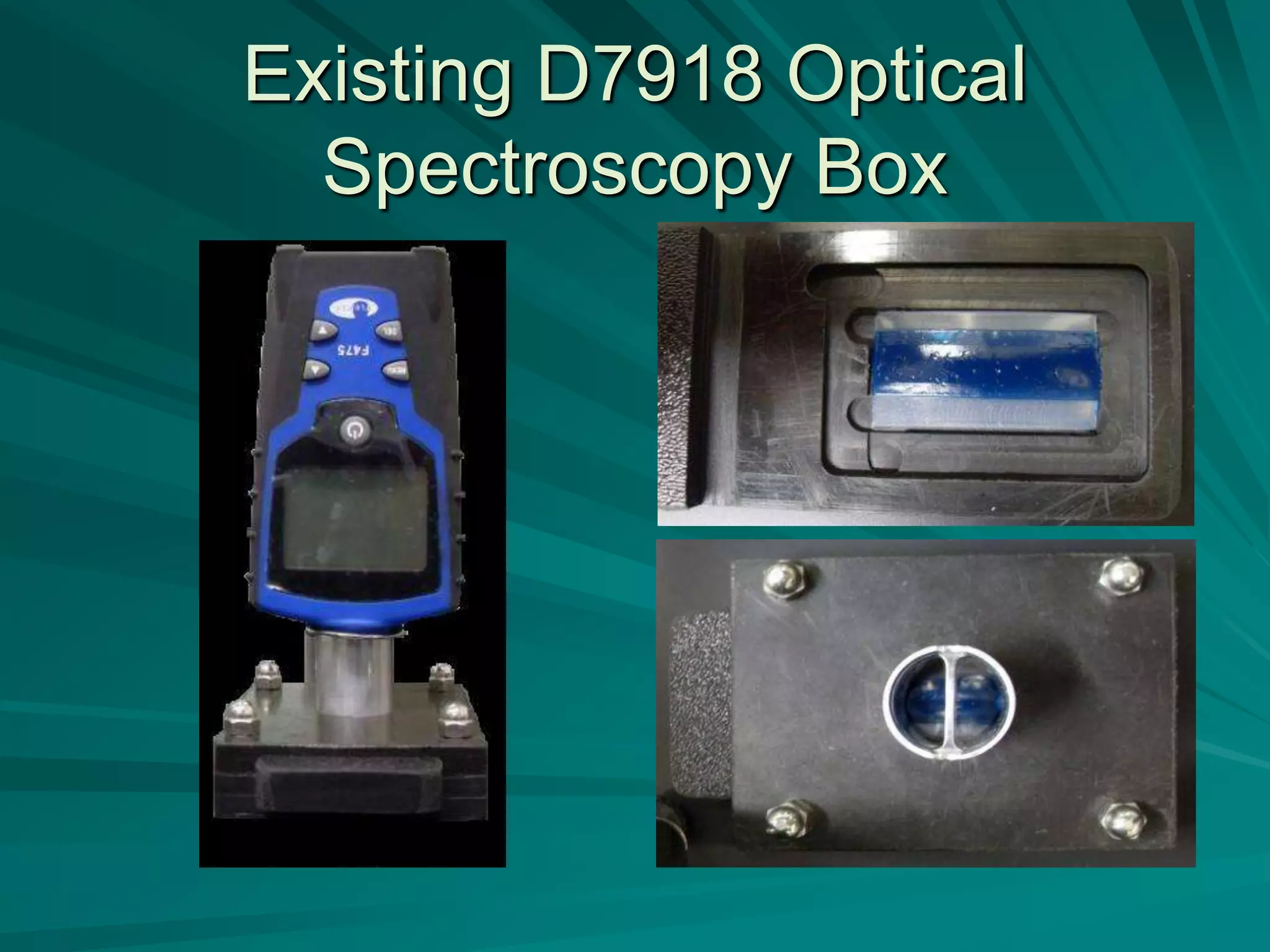

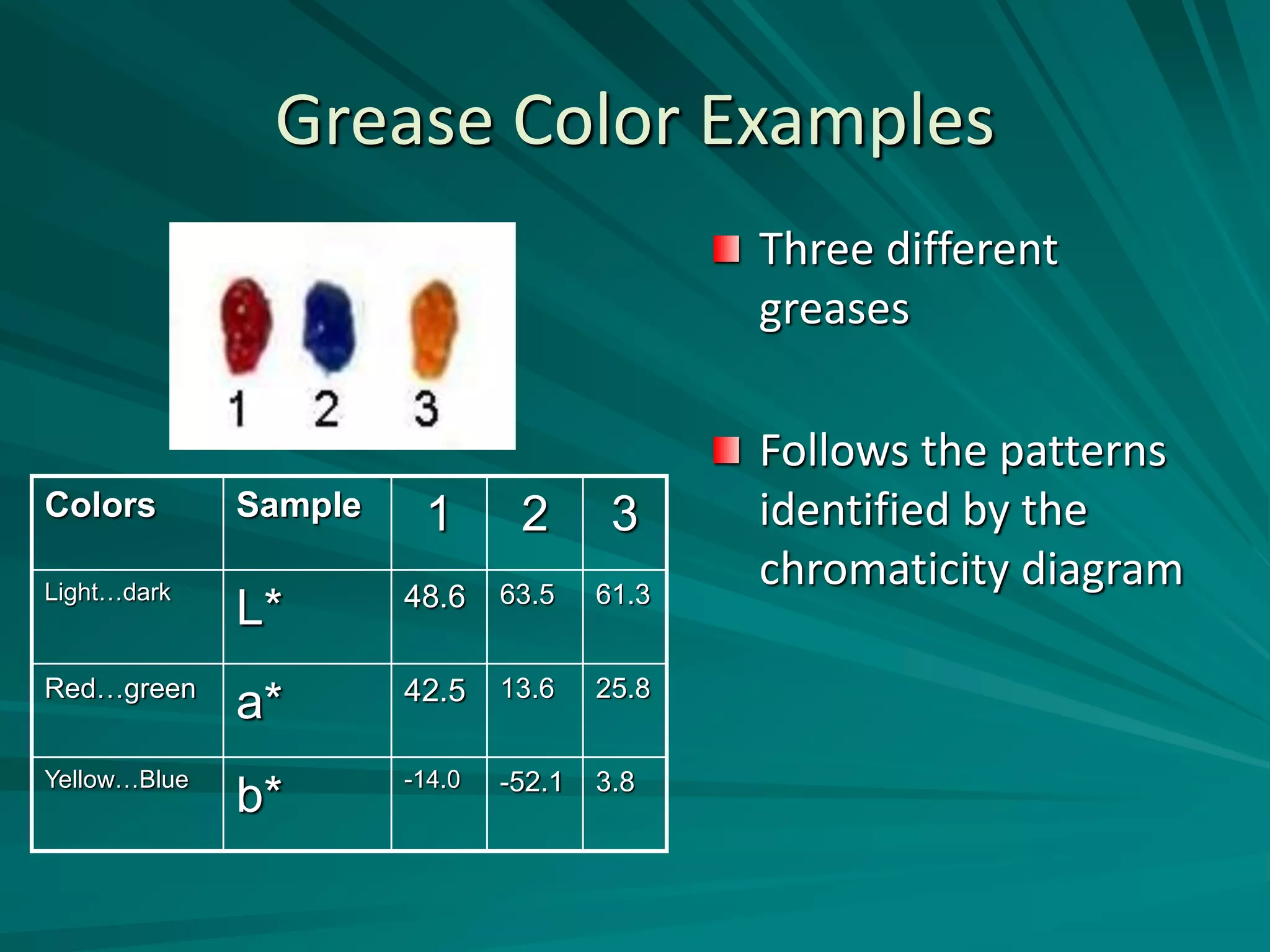

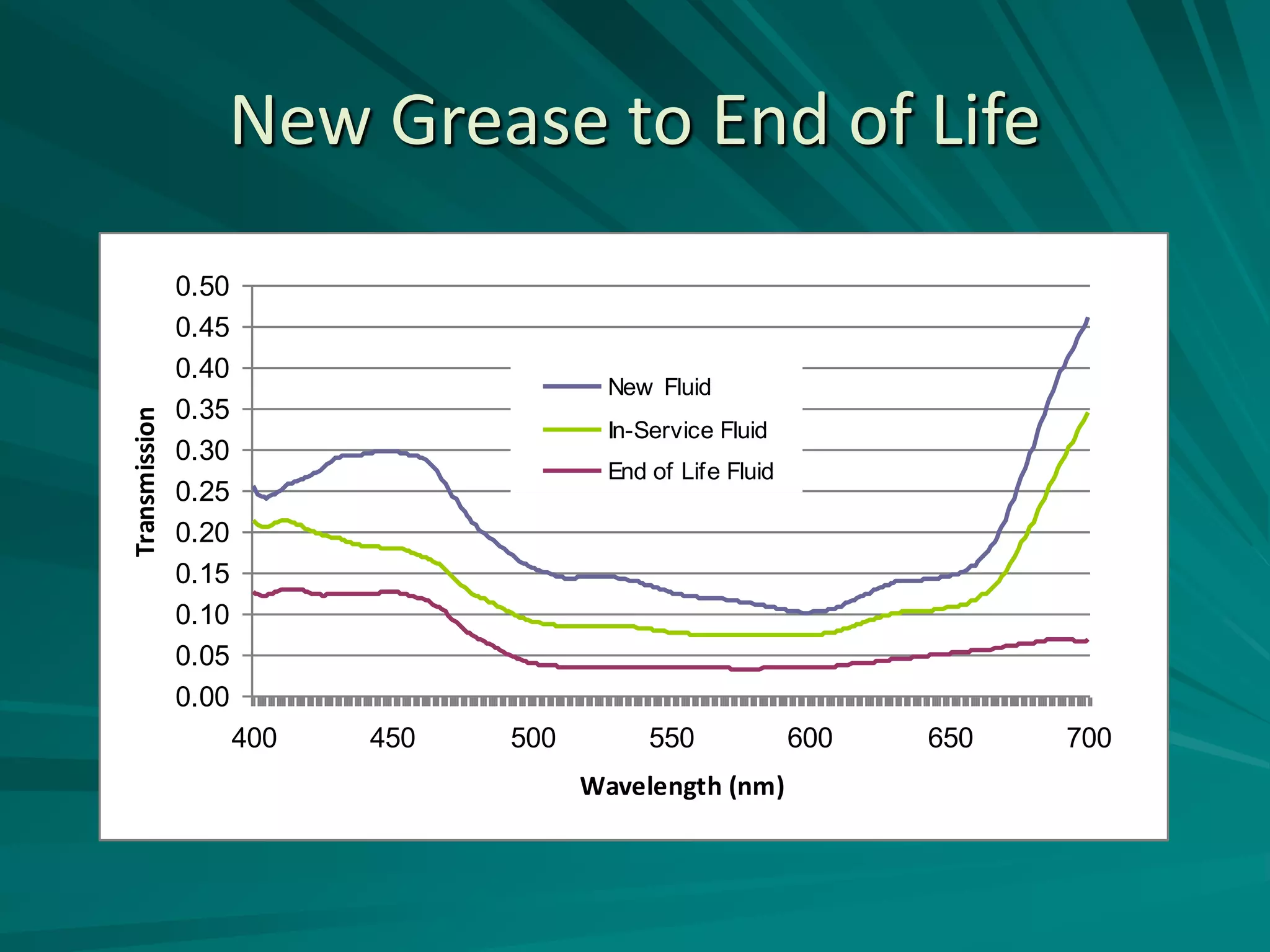

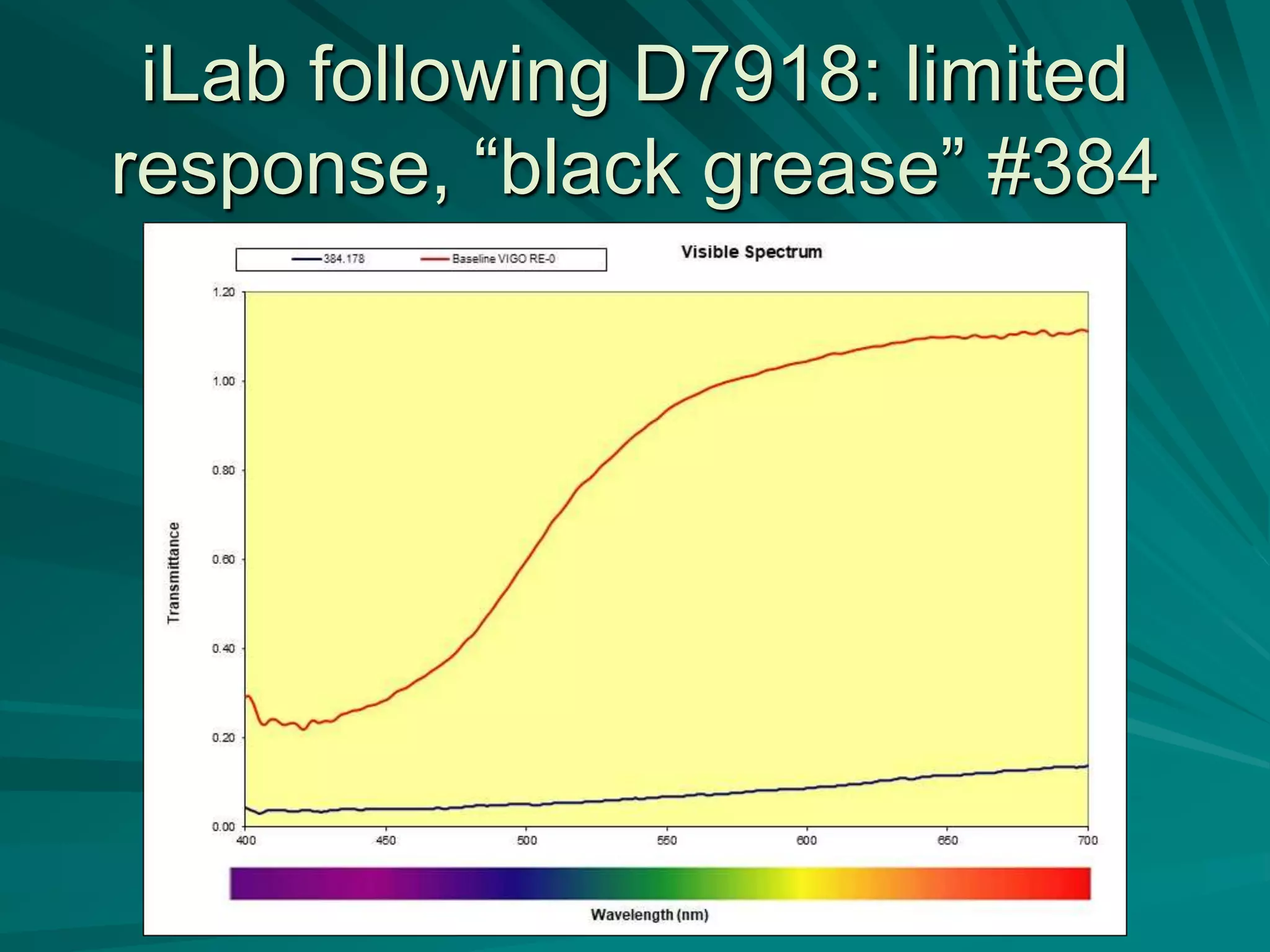

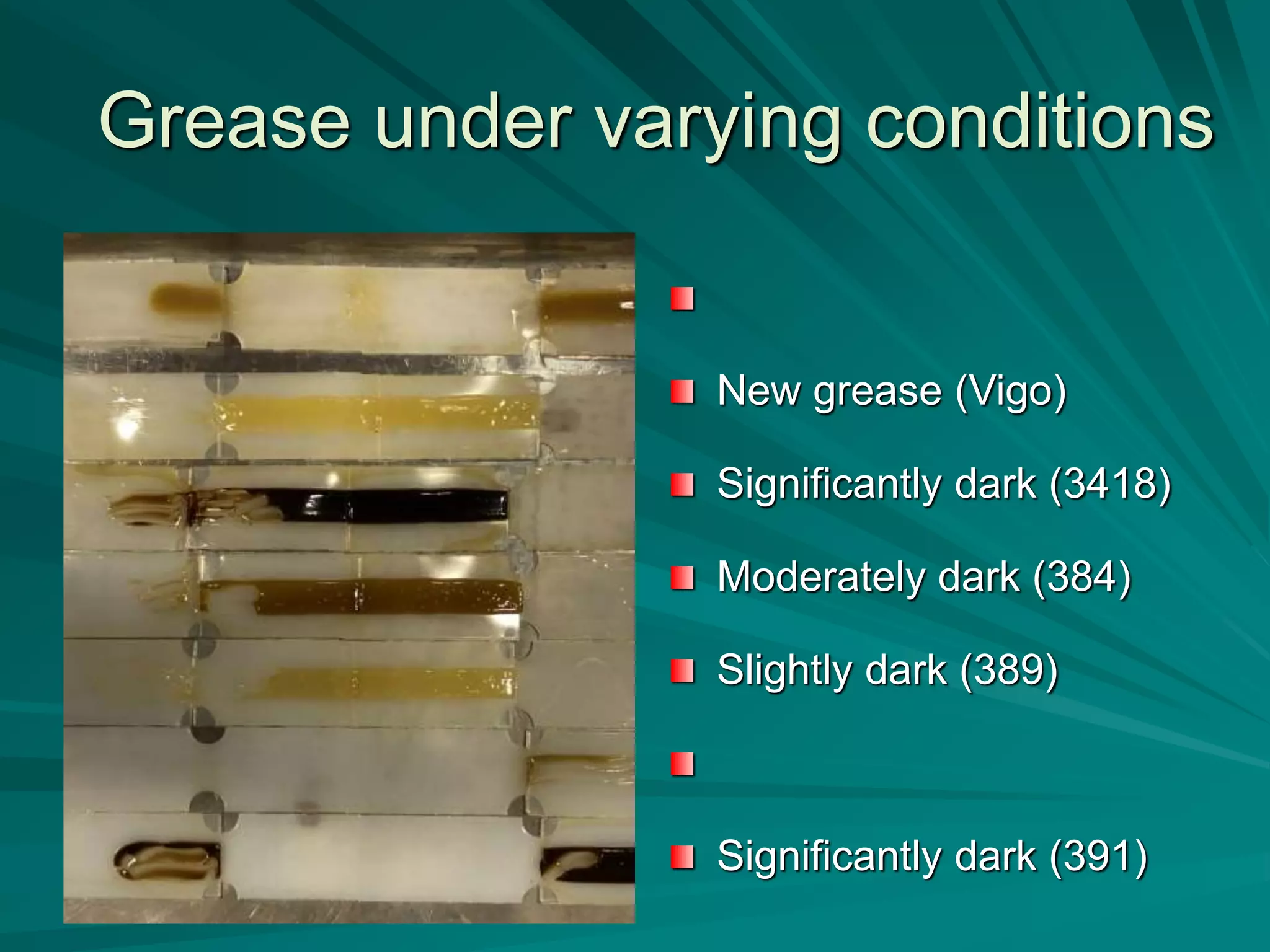

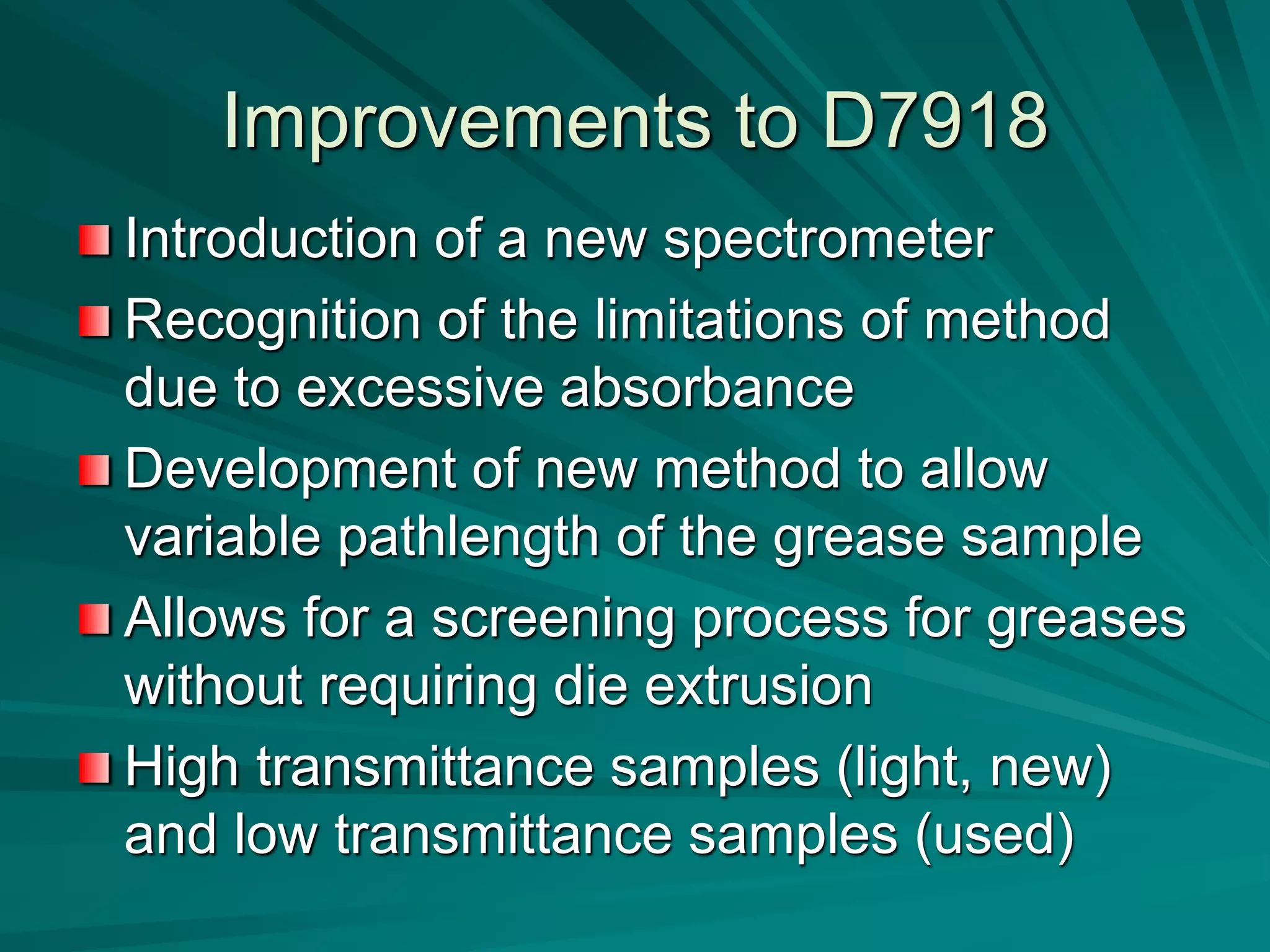

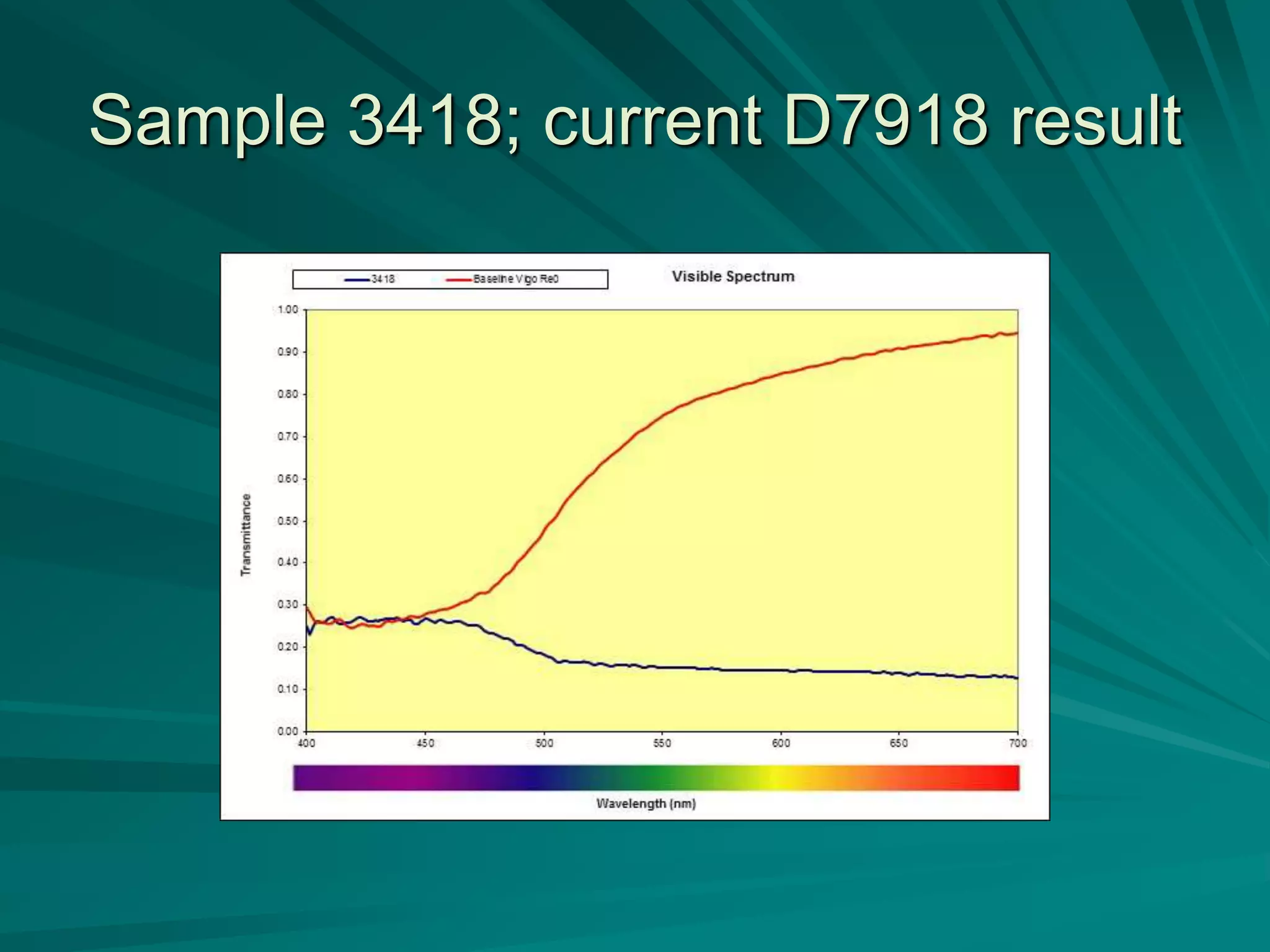

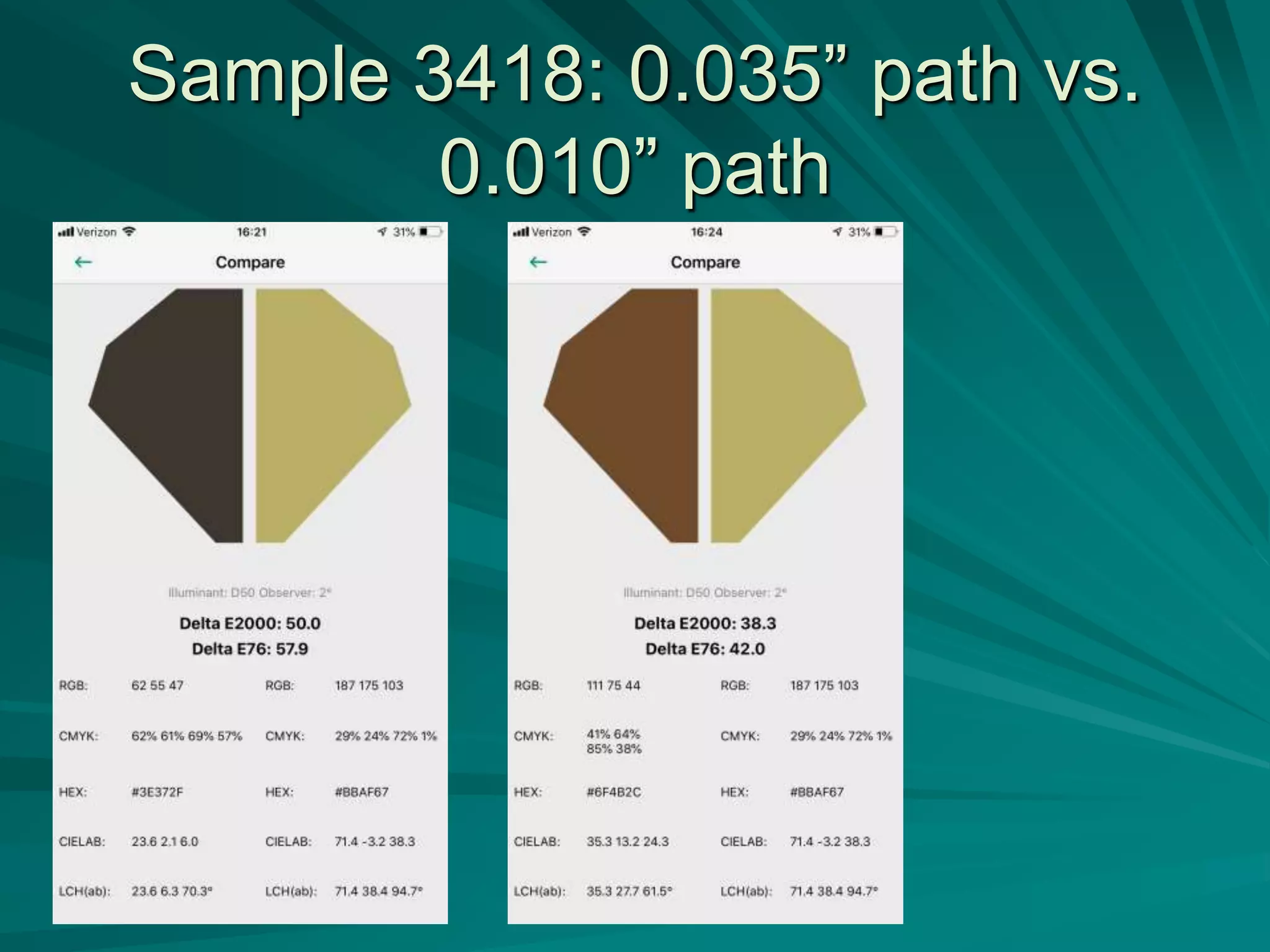

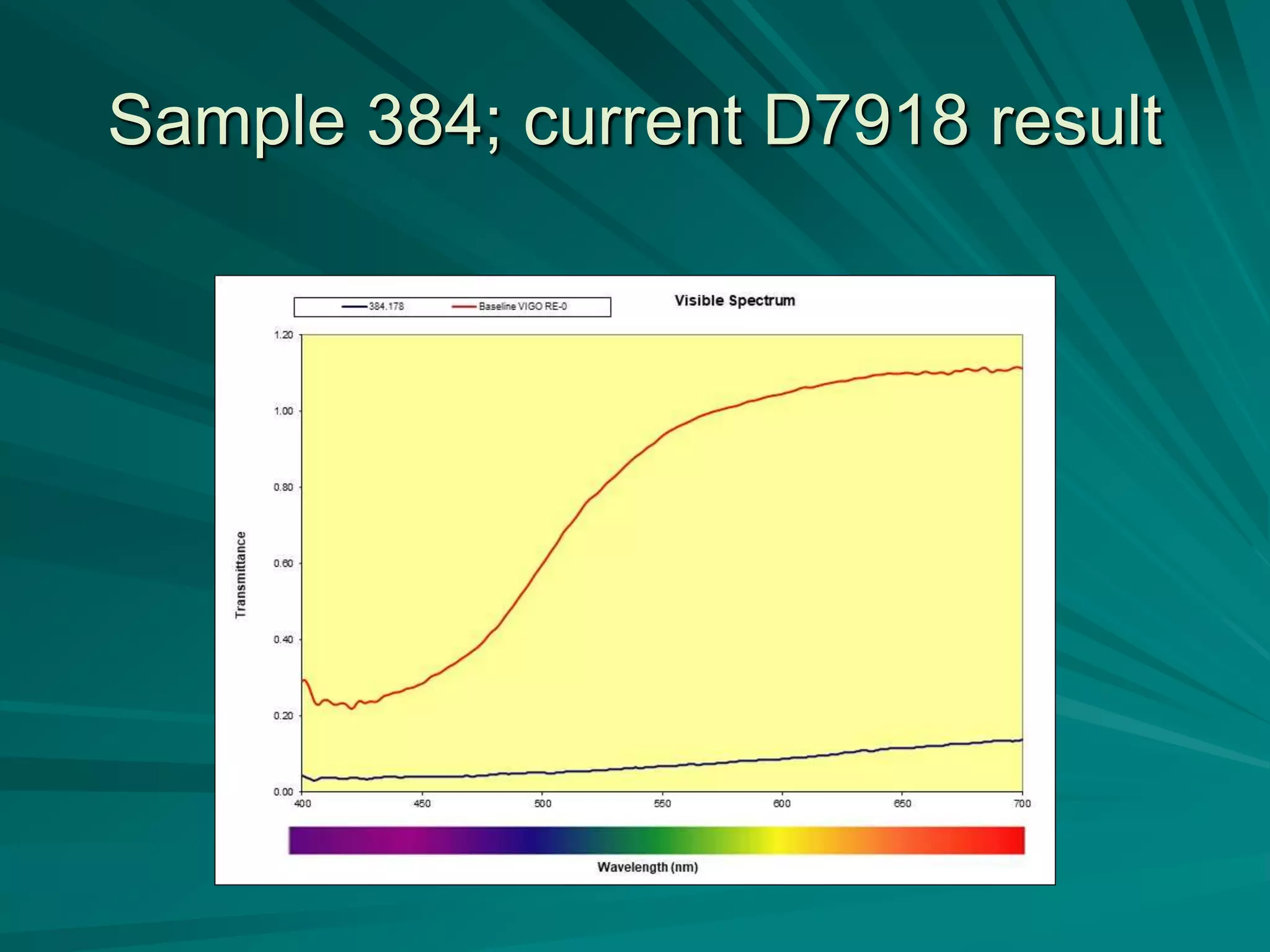

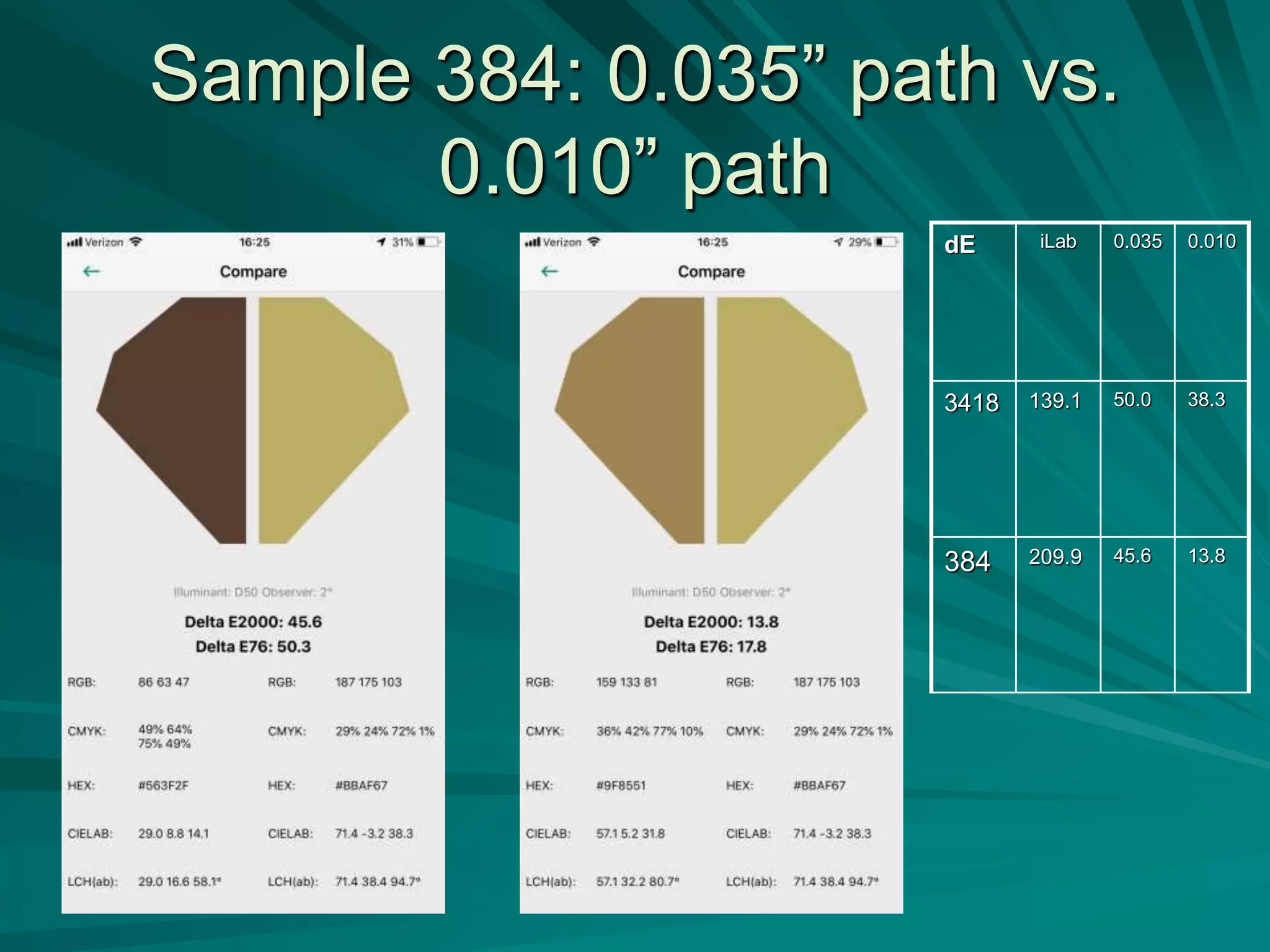

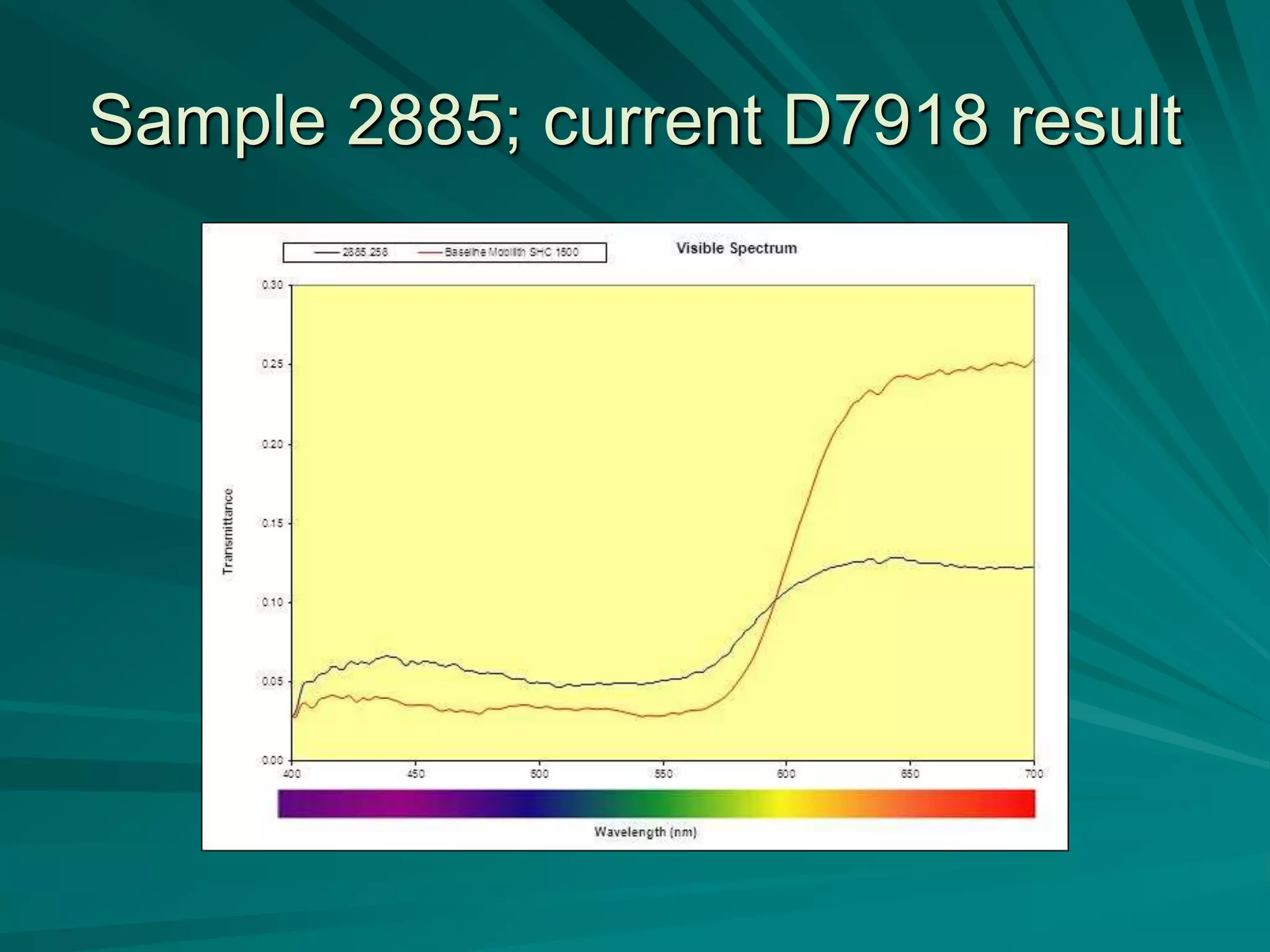

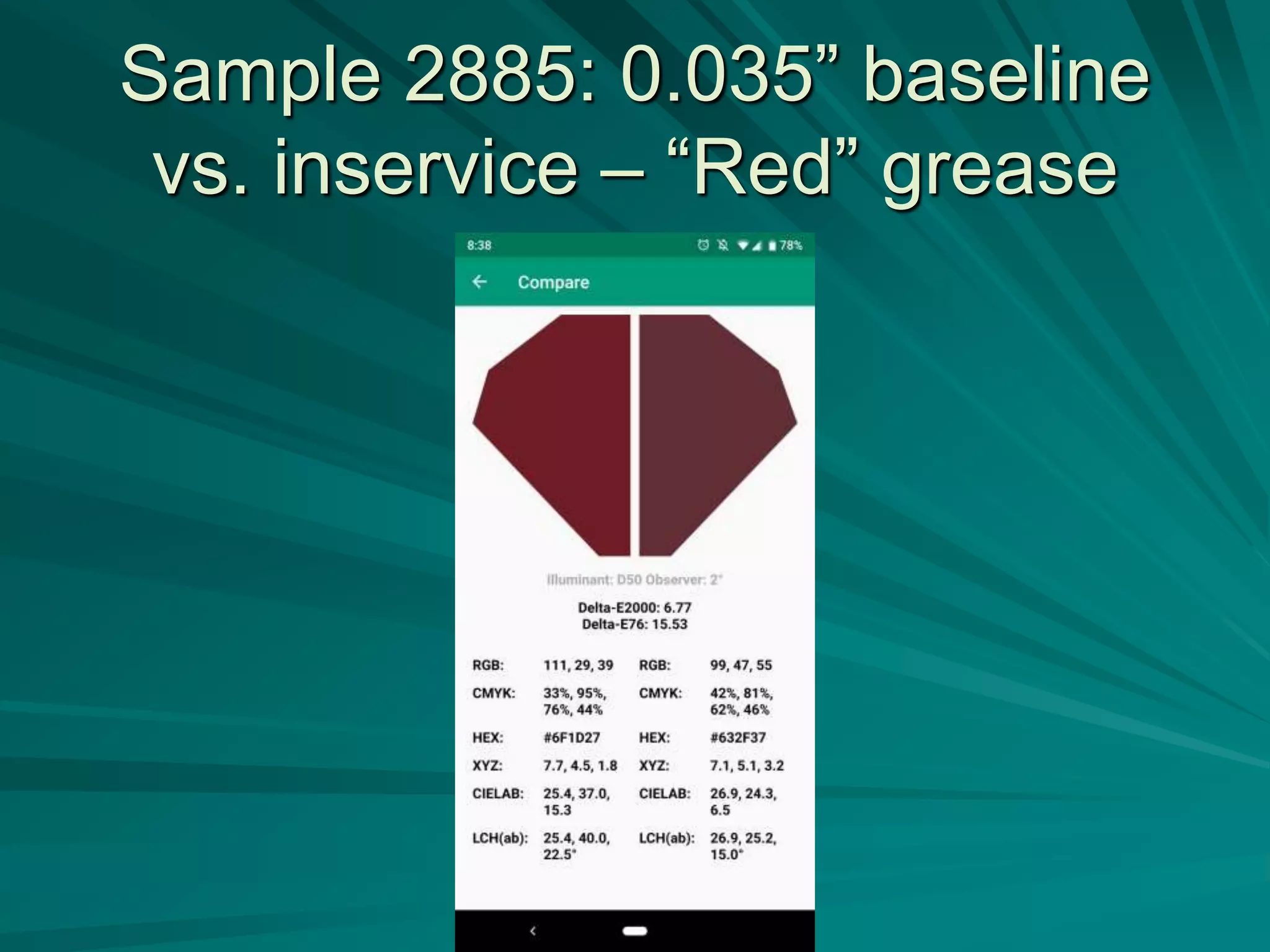

The document outlines an enhancement to the existing ASTM D7918 methodology for evaluating grease color using colorimetric spectroscopy. It introduces a new spectrometer that allows for variable pathlength assessment, addressing limitations from excessive absorbance in standard testing. Proposed next steps include integrating a new colorimeter, revising the ASTM standard, and continuing research on grease-specific color relationships.