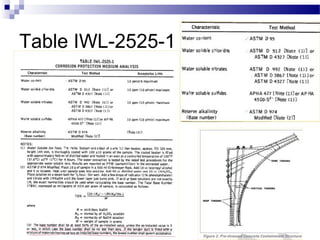

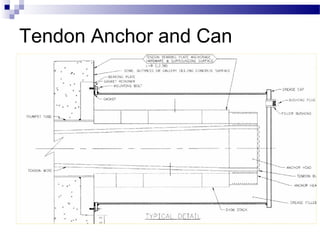

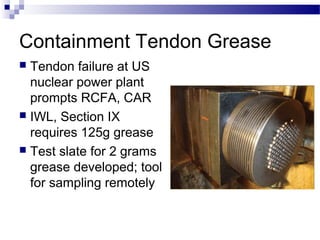

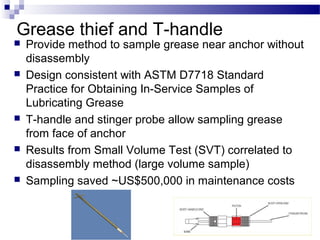

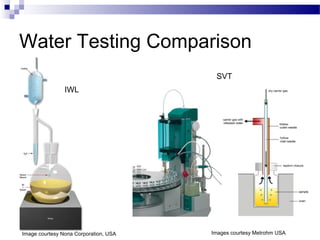

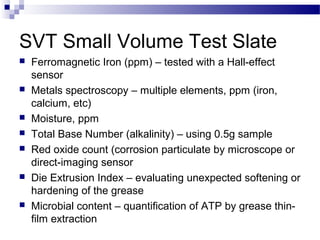

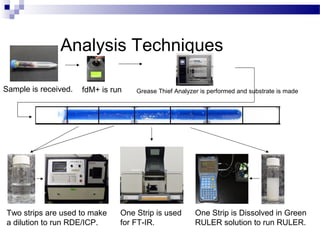

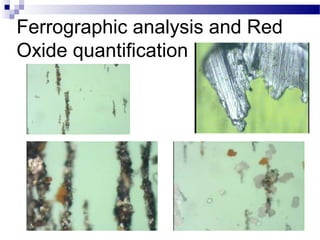

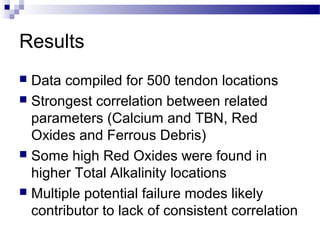

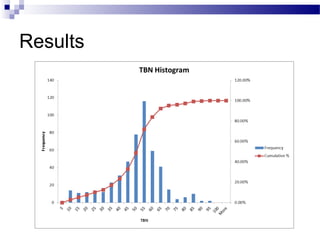

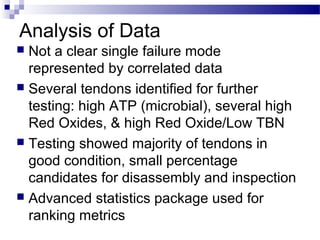

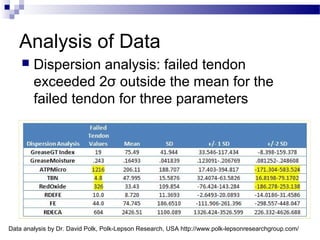

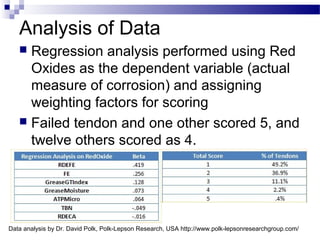

The document discusses advanced sampling and analysis methods for post-tensioned concrete tendon greases, emphasizing the shortcomings of current testing standards and the need for innovative approaches. It introduces new sampling tools and small volume testing techniques that are more efficient and cost-effective compared to traditional methods. Findings indicate that these new methods may enhance the detection of failure modes and correlate well with established testing procedures.