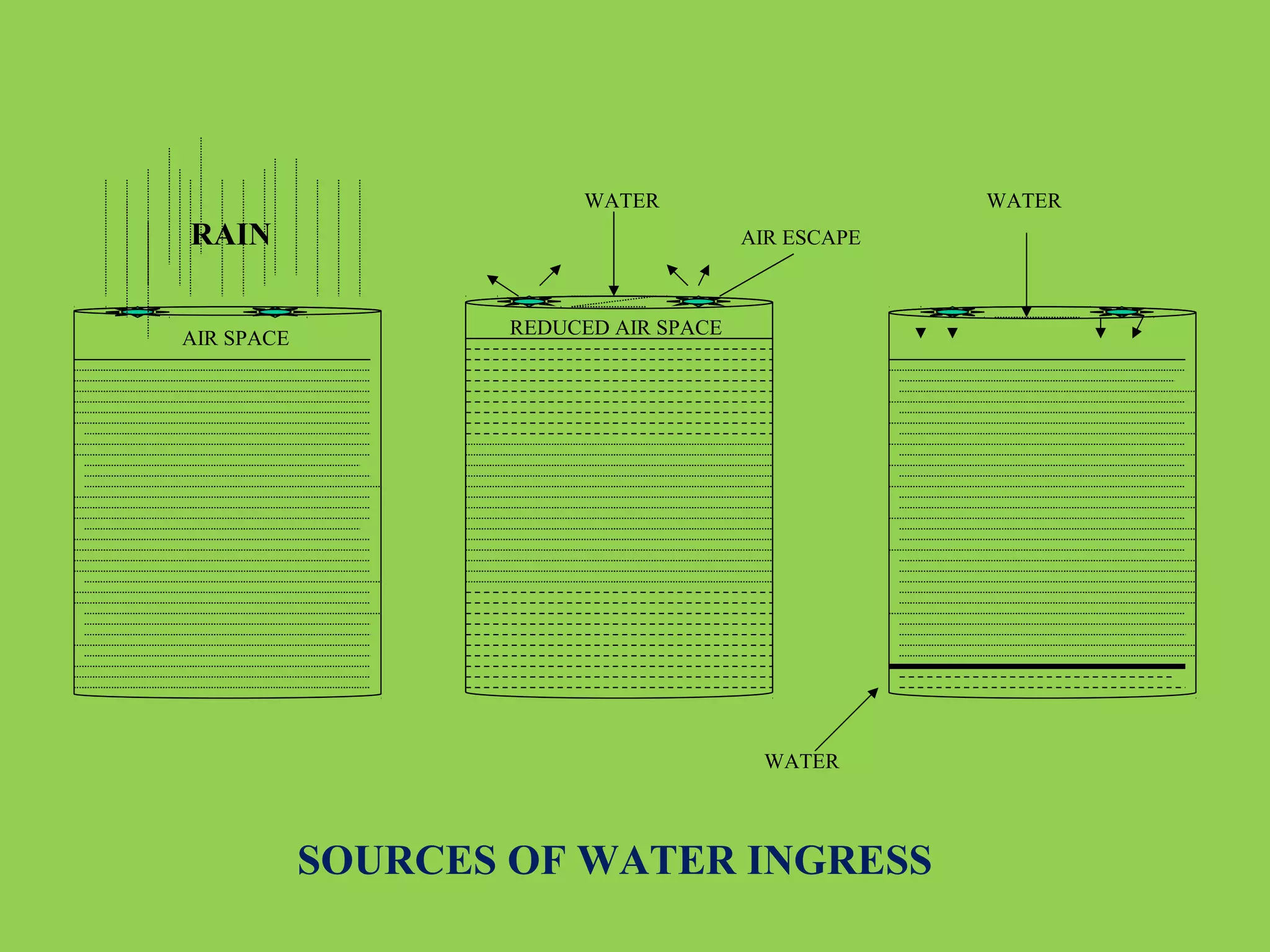

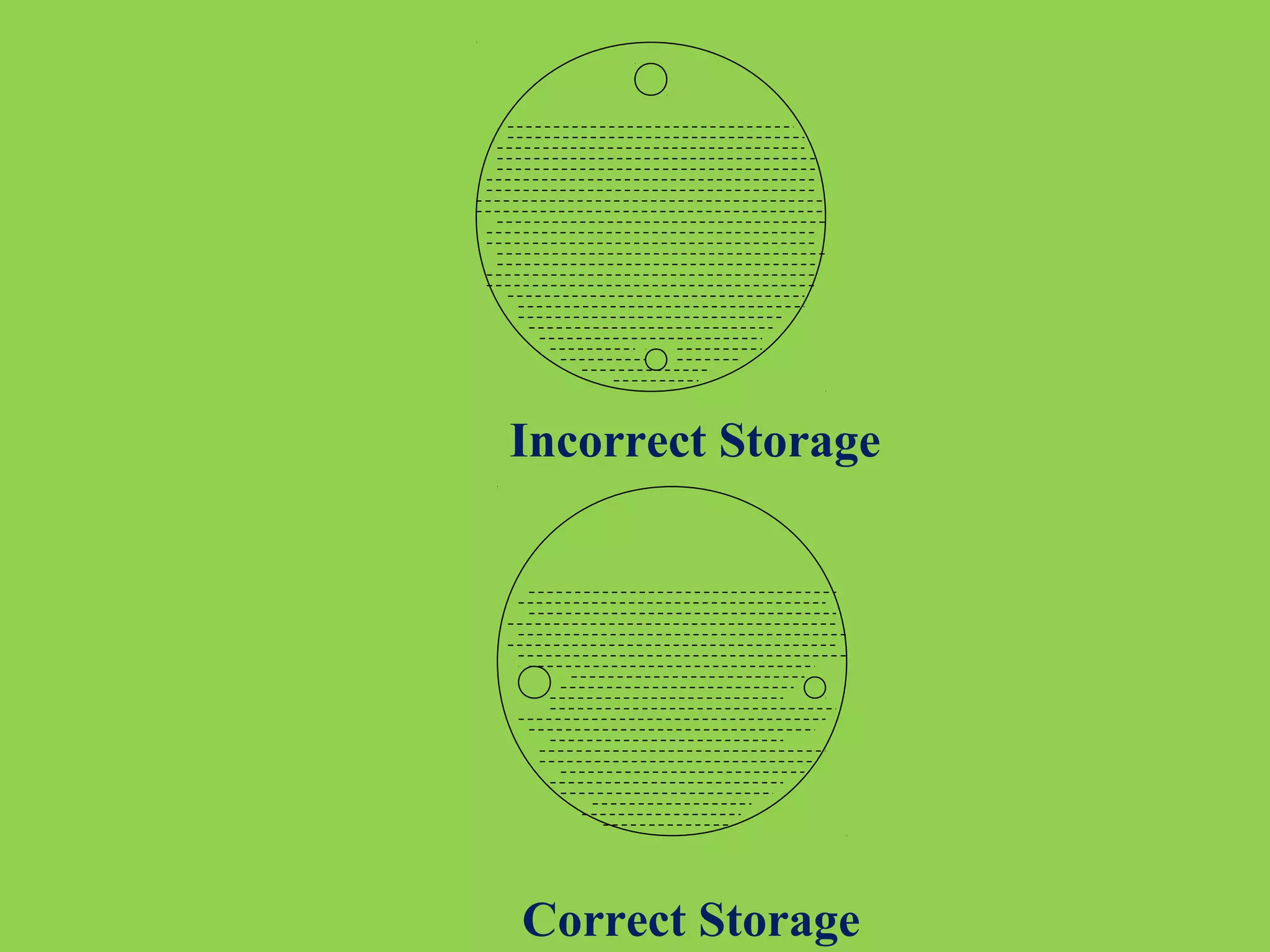

The document discusses the proper storage and handling of lubricants such as oil and grease. It notes that lubricants generally come in oil drums or grease drums that should be stored indoors or outdoors in positions that prevent water ingress. When storing outdoors, drums should be covered. Grease drums should be stored vertically indoors or covered outdoors. Lubricants should be dispensed in covered containers and handling practices should avoid contamination. Proper maintenance and calibration of dispensing equipment is also important to ensure the right quantity and quality of lubricants.