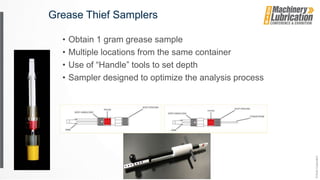

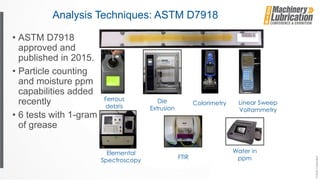

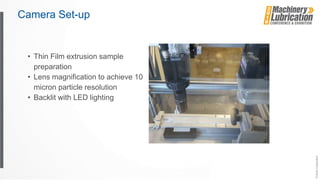

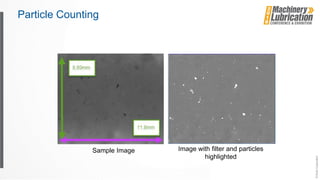

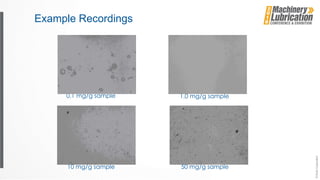

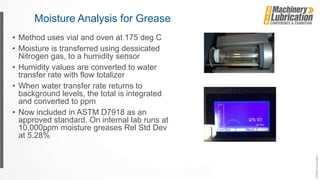

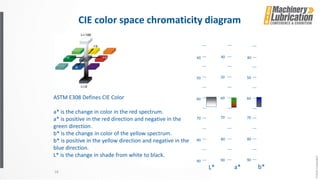

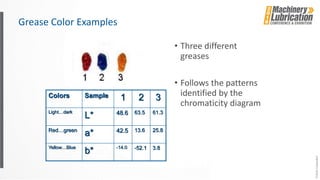

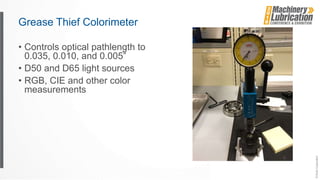

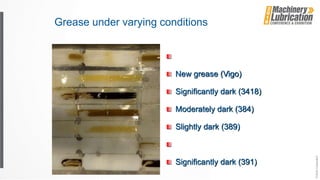

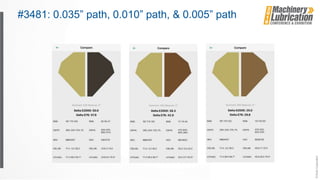

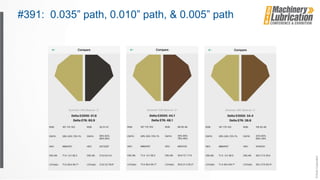

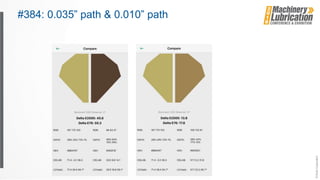

This document discusses establishing an effective grease analysis program to monitor critical equipment lubricated with grease. It recommends the following steps: 1) select equipment for inclusion, 2) evaluate grease flow to determine sampling locations, 3) select appropriate sampling equipment, 4) establish standard sampling procedures, 5) create appropriate test methods, 6) generate a sampling schedule, and 7) review results for issues and implement proactive measures. The document also describes various grease sampling and analysis techniques like particle counting, moisture analysis, and color measurement that can identify contamination, wear, or grease degradation issues.