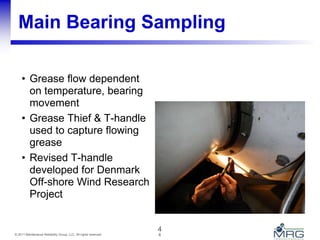

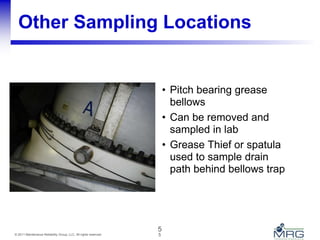

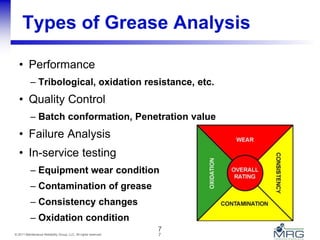

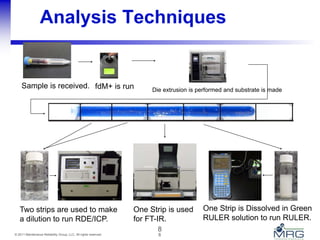

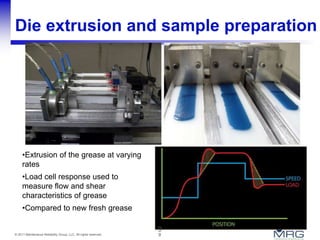

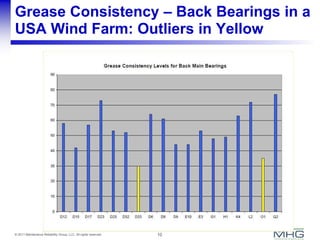

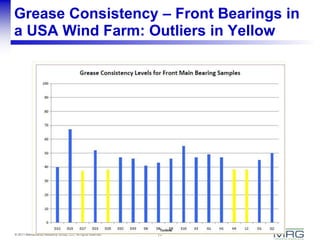

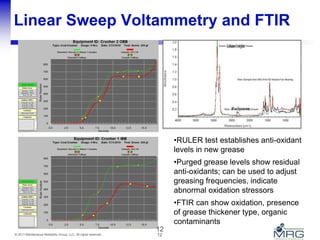

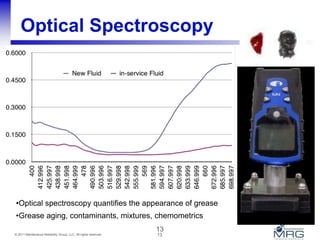

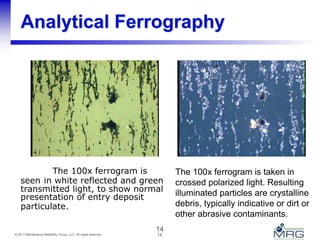

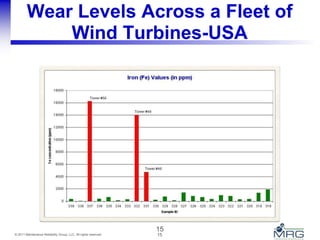

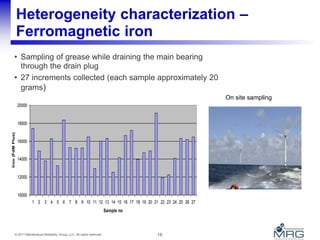

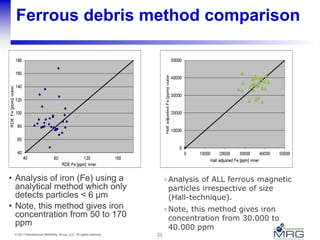

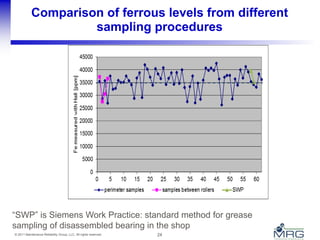

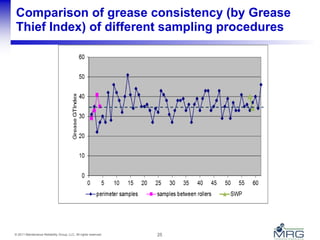

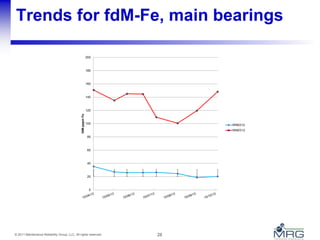

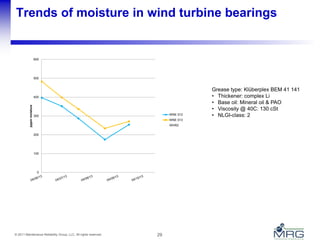

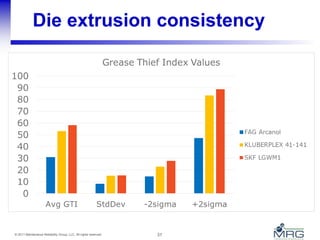

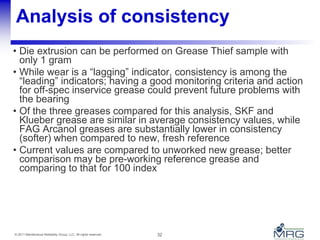

This document provides a comprehensive overview of grease sampling and analysis techniques used in wind turbine applications, emphasizing the importance of maintaining grease quality for equipment reliability. It outlines various sampling techniques, analysis methods, and the results of a two-year project involving major offshore wind operators, showcasing advancements in grease characterization and monitoring. Key findings indicate that in-service grease analysis can effectively complement existing condition monitoring systems and facilitate early detection of abnormalities, leading to cost-effective maintenance strategies.