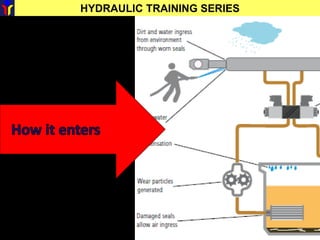

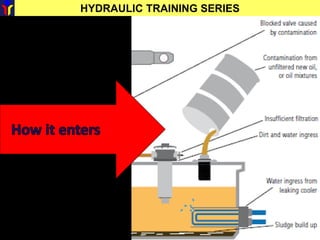

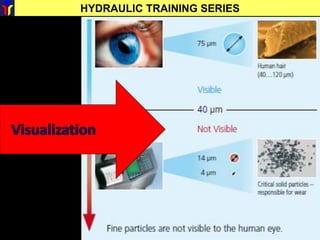

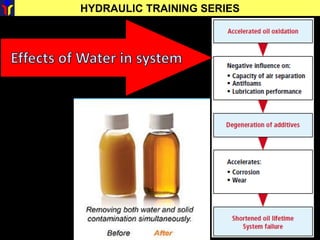

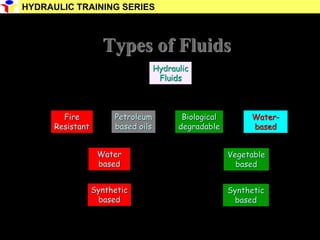

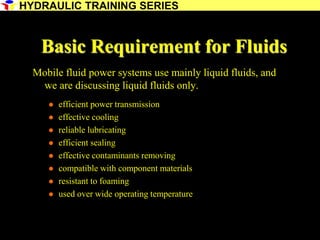

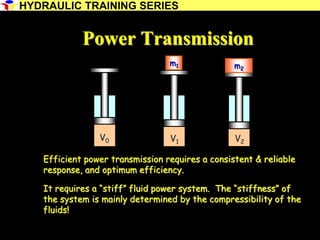

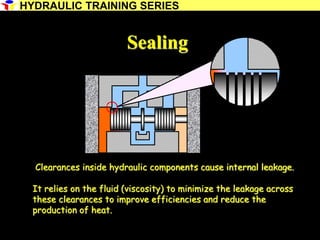

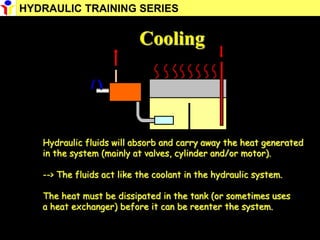

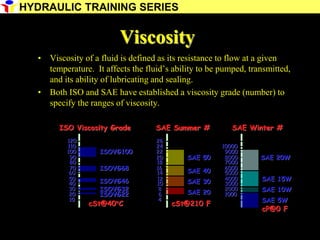

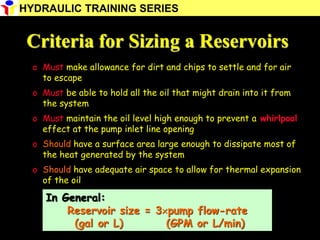

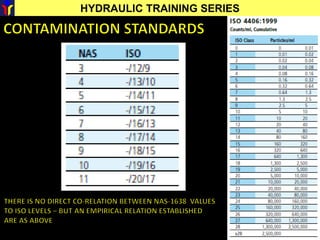

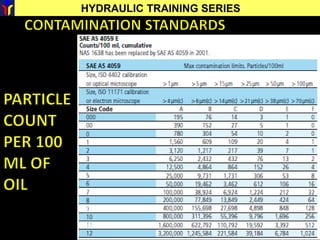

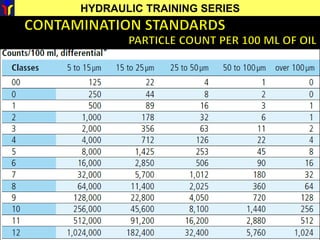

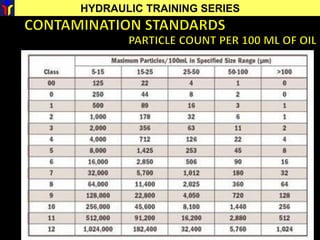

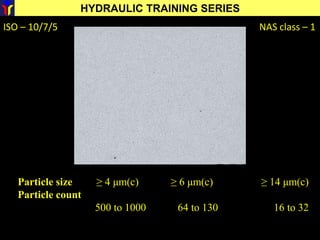

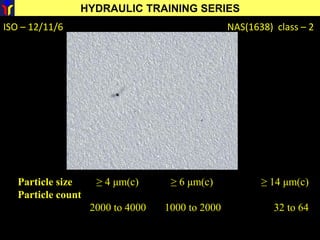

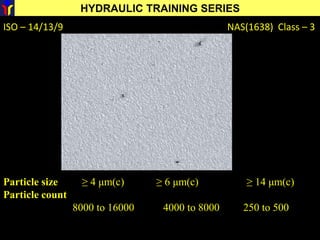

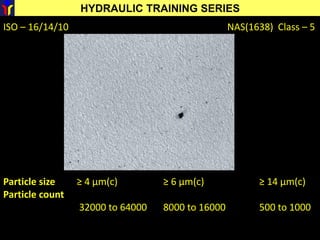

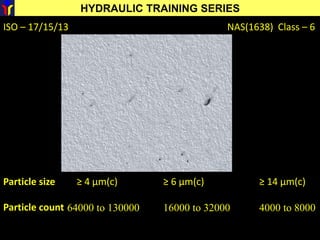

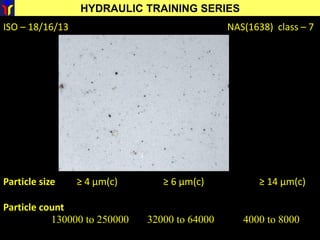

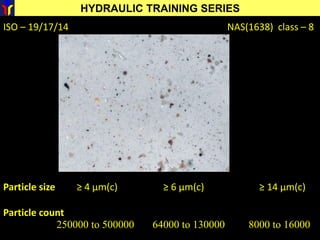

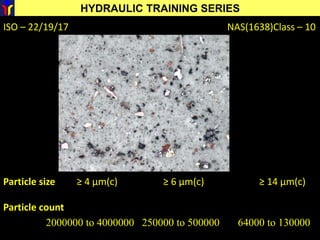

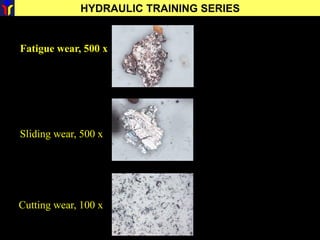

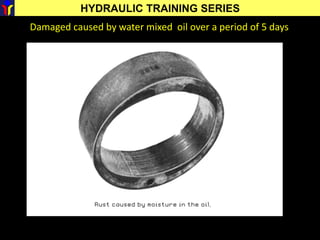

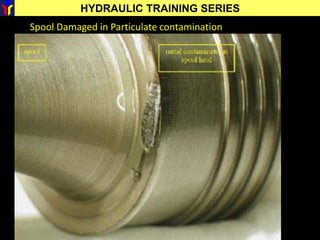

The document outlines key aspects of hydraulic training, focusing on oil contamination and the essential requirements for hydraulic fluids, including efficient power transmission, lubrication, sealing, cooling, and contaminants removal. It emphasizes the importance of fluid properties and the selection criteria for different types of hydraulic fluids based on their specific roles and environmental impact. Additionally, it discusses categories of contamination, sources of solid contamination, and fluid conditioning methods to ensure the reliability and performance of hydraulic systems.