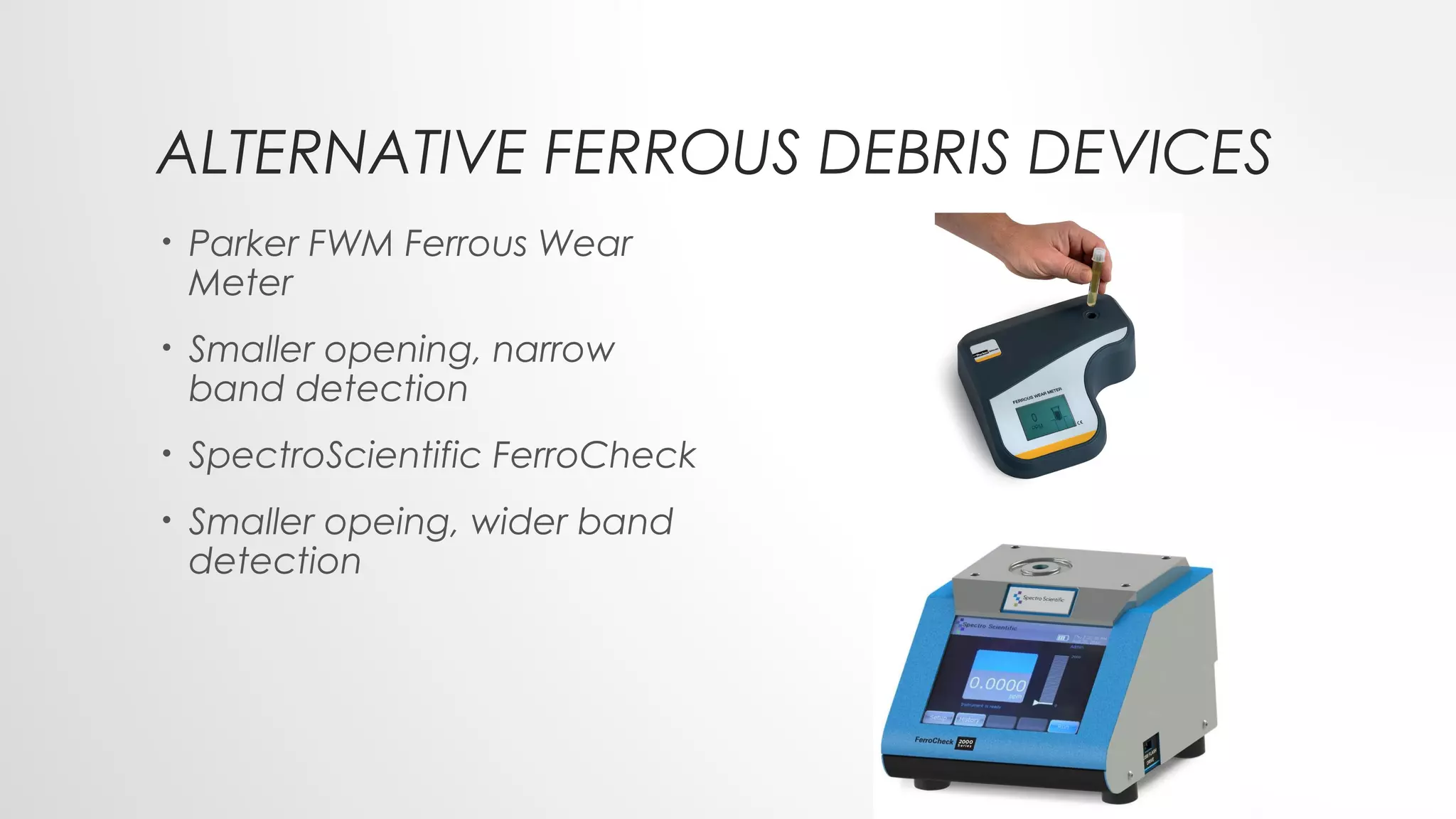

The document outlines the changes in ferrous debris measurement options for grease thief samplers under ASTM D7918, emphasizing the need for design adjustments to maintain functionality in various applications. It highlights recent approvals and enhancements in analysis techniques, along with the discontinuation of certain models. Next steps include developing alternative devices and revising D7918 to support new calibration and testing methodologies.