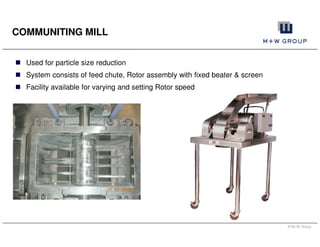

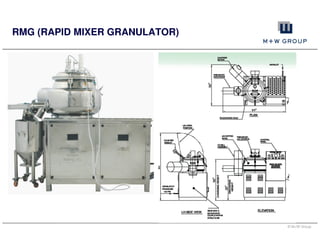

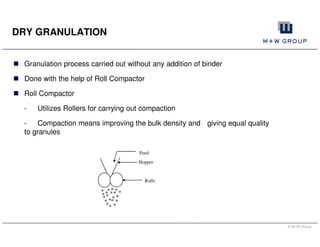

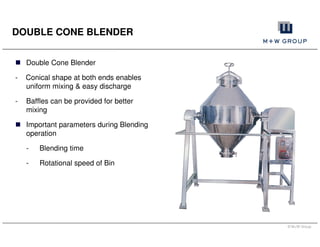

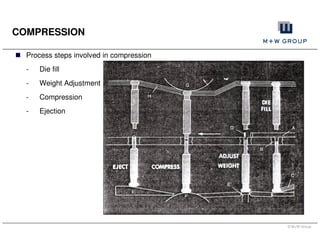

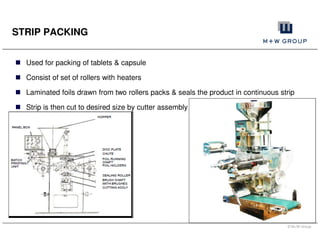

This document describes various types of equipment used in pharmaceutical manufacturing, including sampling booths, dispensing booths, sifting equipment, mills, granulation equipment, blending equipment, tablet compression machines, coating equipment, and packaging equipment. It provides details on the components, functioning, and purposes of different pieces of equipment for processes like sampling, milling, granulation, blending, compression, coating, and packaging.