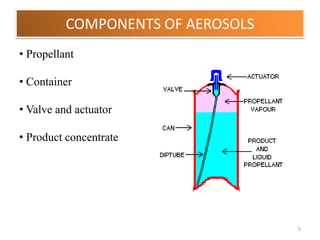

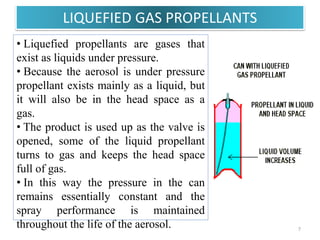

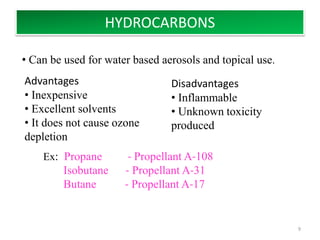

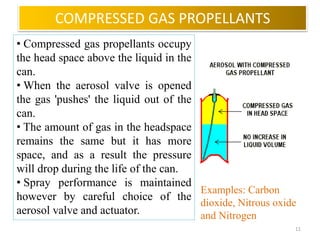

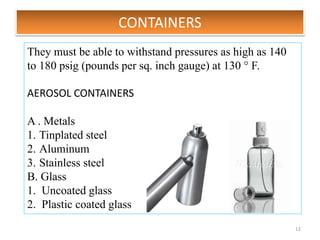

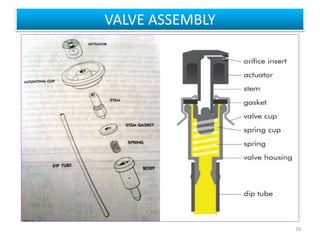

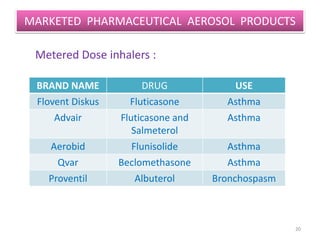

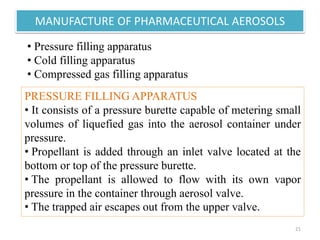

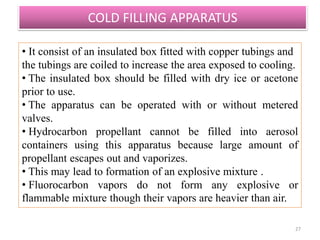

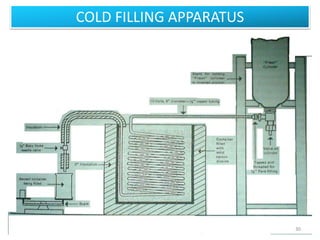

This document provides an overview of inhalation aerosols, including the propellants used, packaging, and filling techniques. It discusses the main components of aerosols like propellants, containers, valves, and actuators. The two main types of propellants are liquefied gas propellants and compressed gas propellants. It also summarizes the advantages and disadvantages of aerosols as well as the pressure filling and cold filling methods used to manufacture pharmaceutical aerosols.