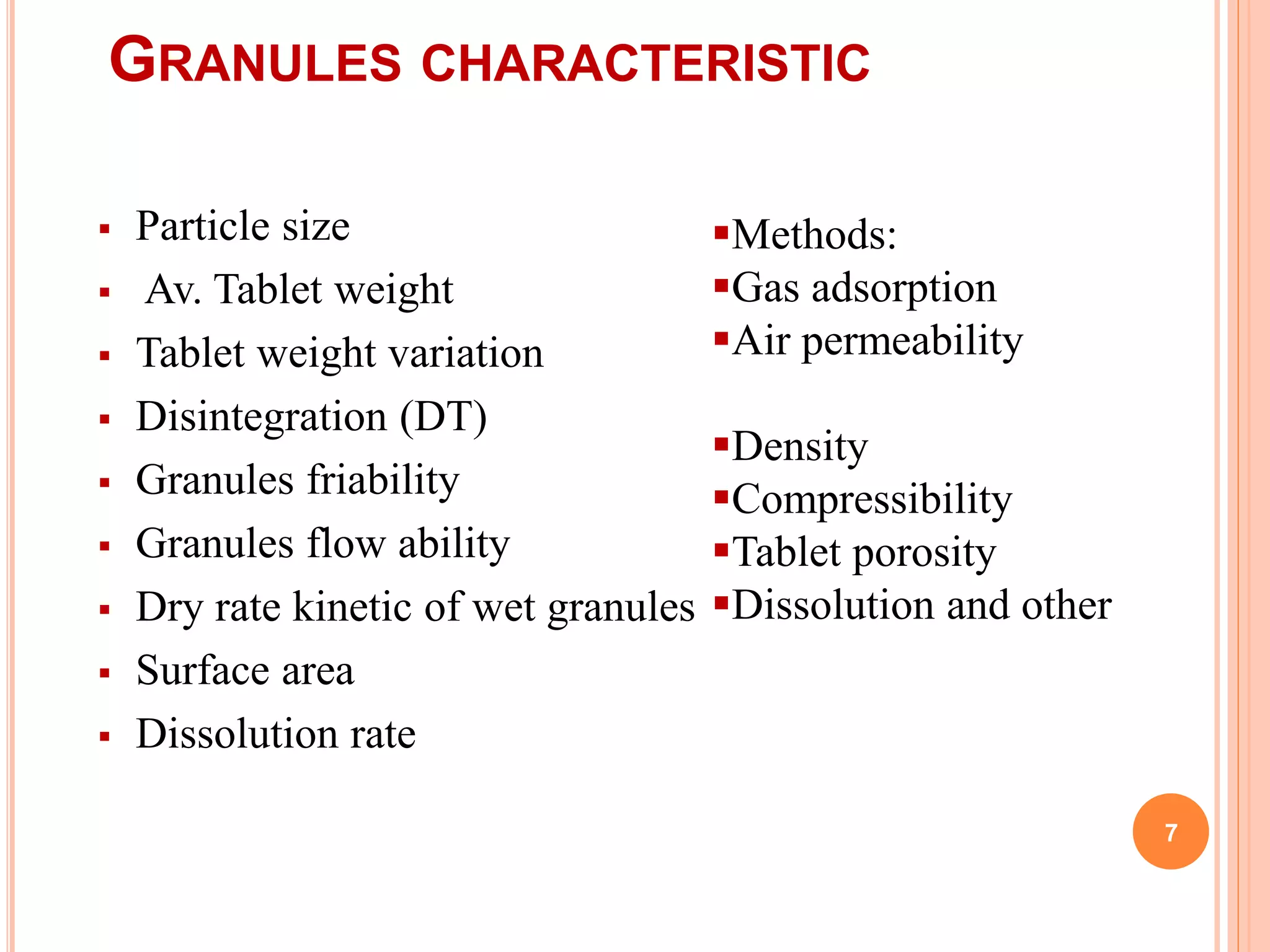

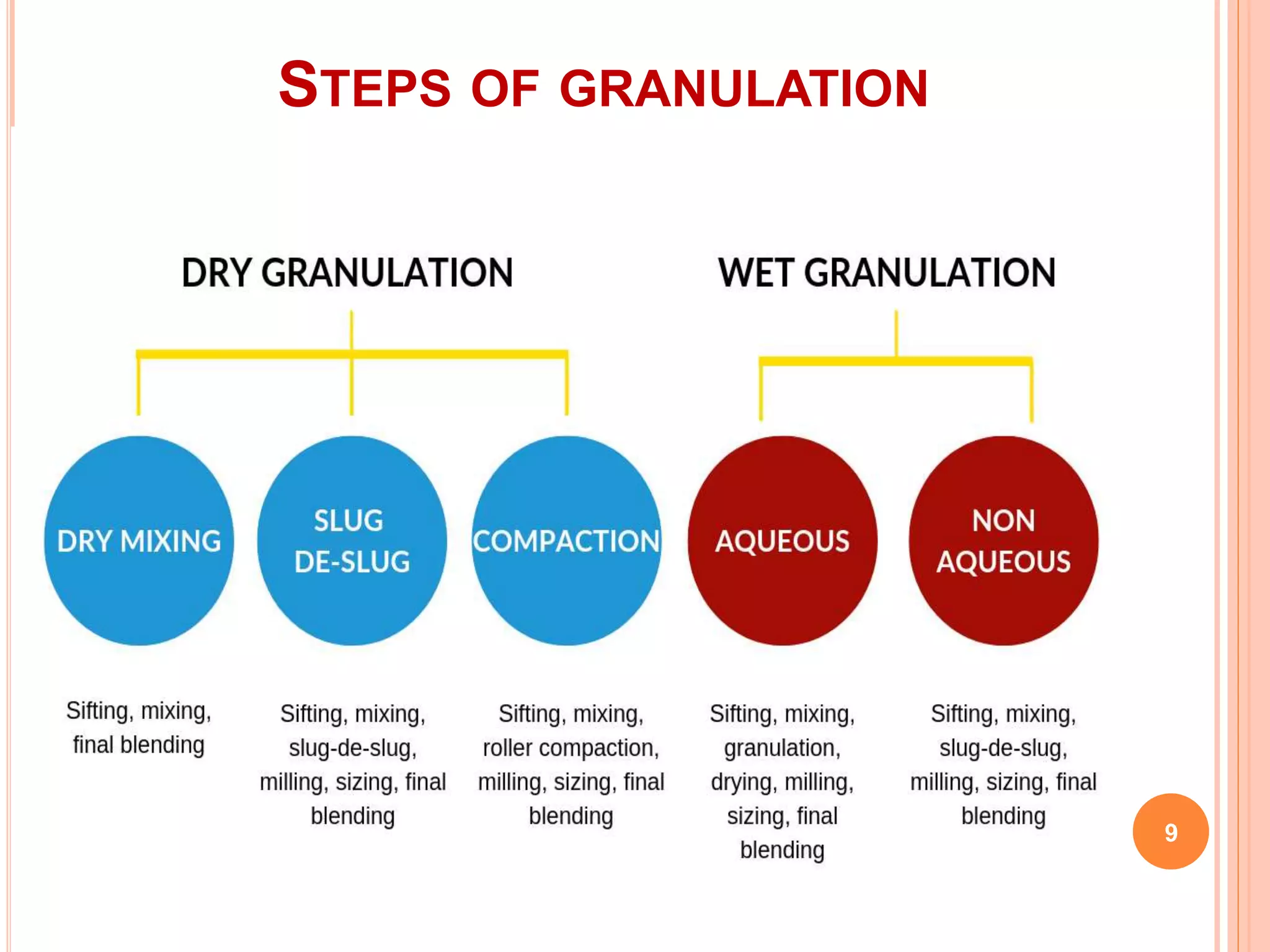

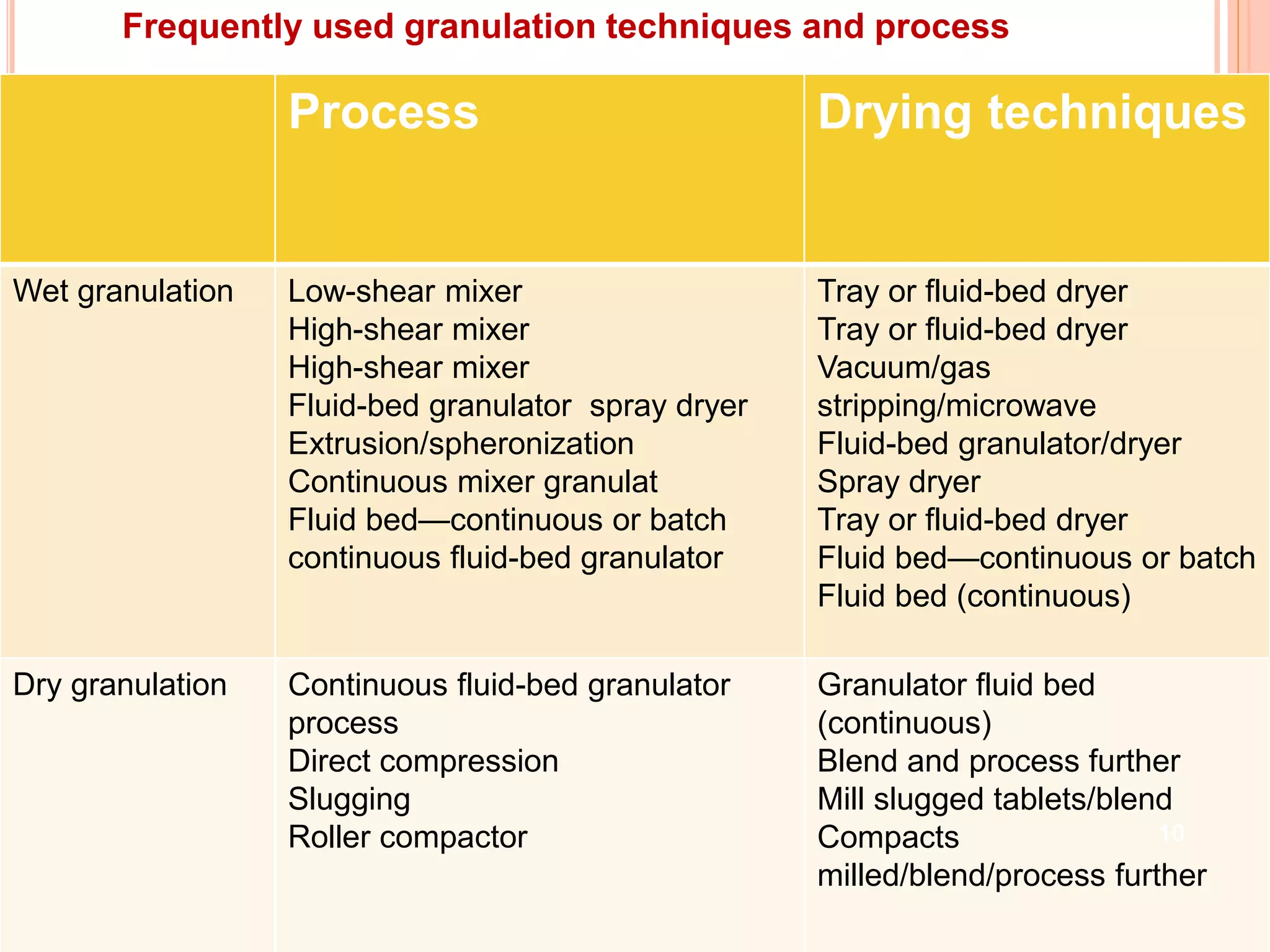

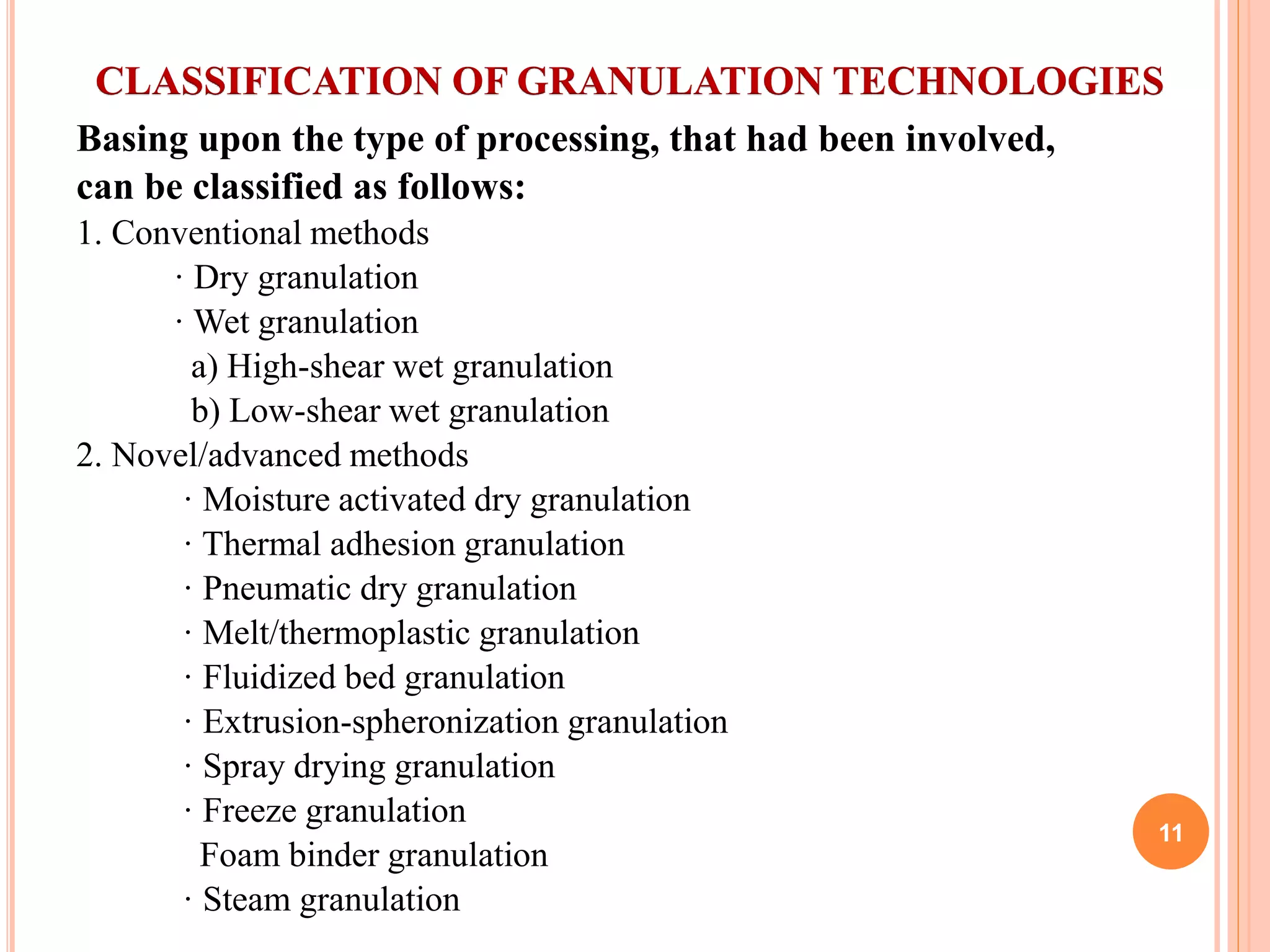

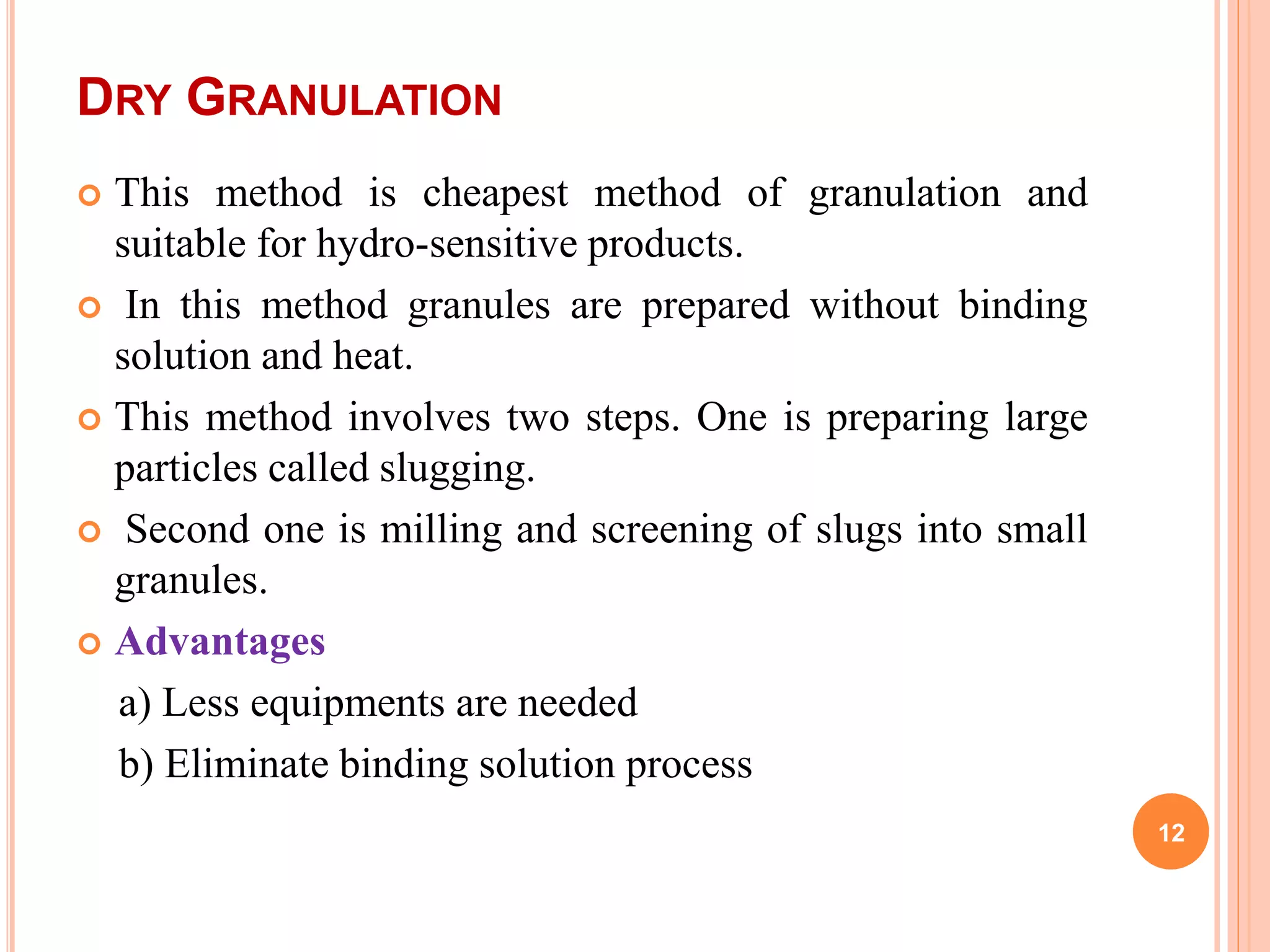

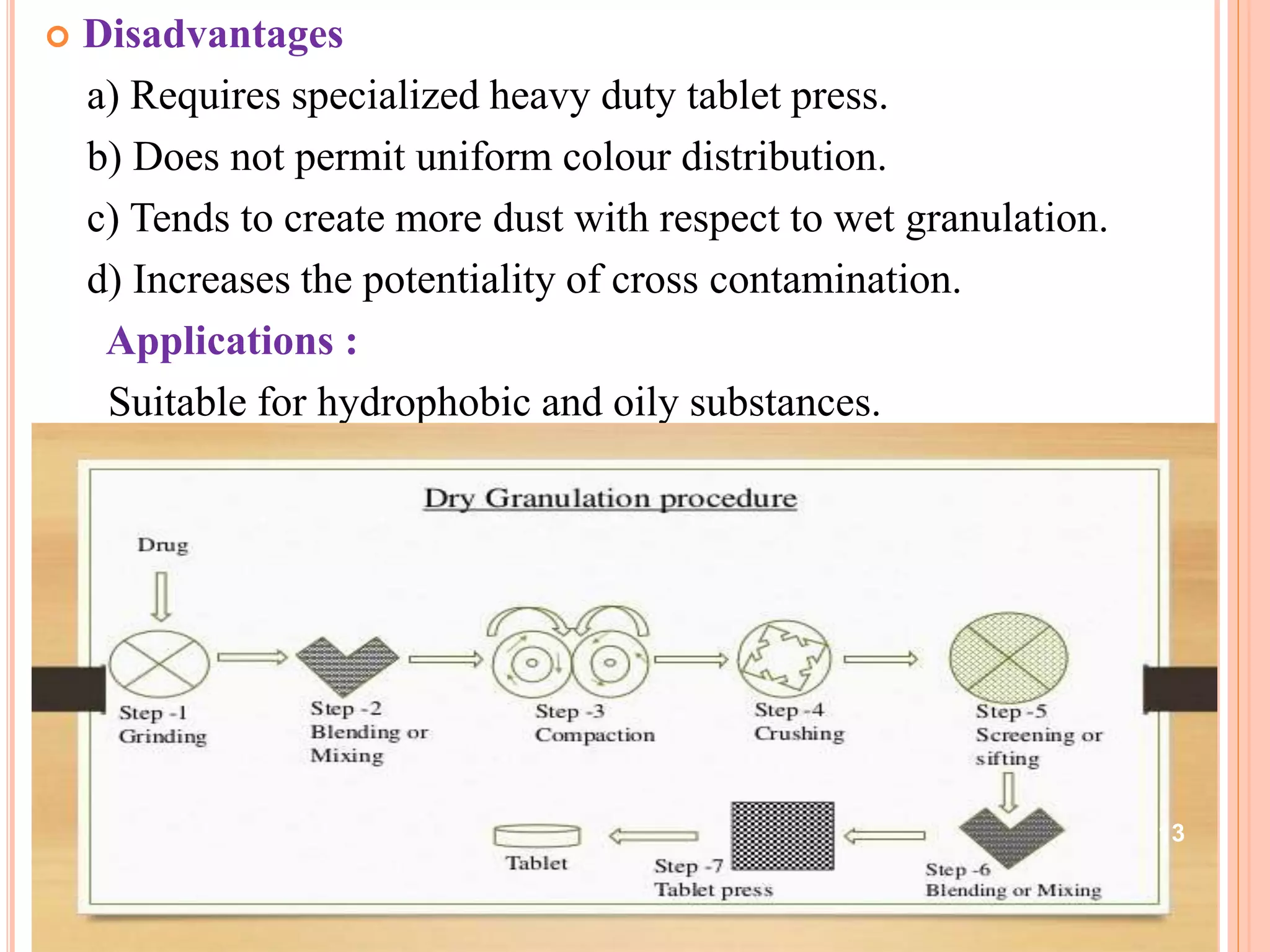

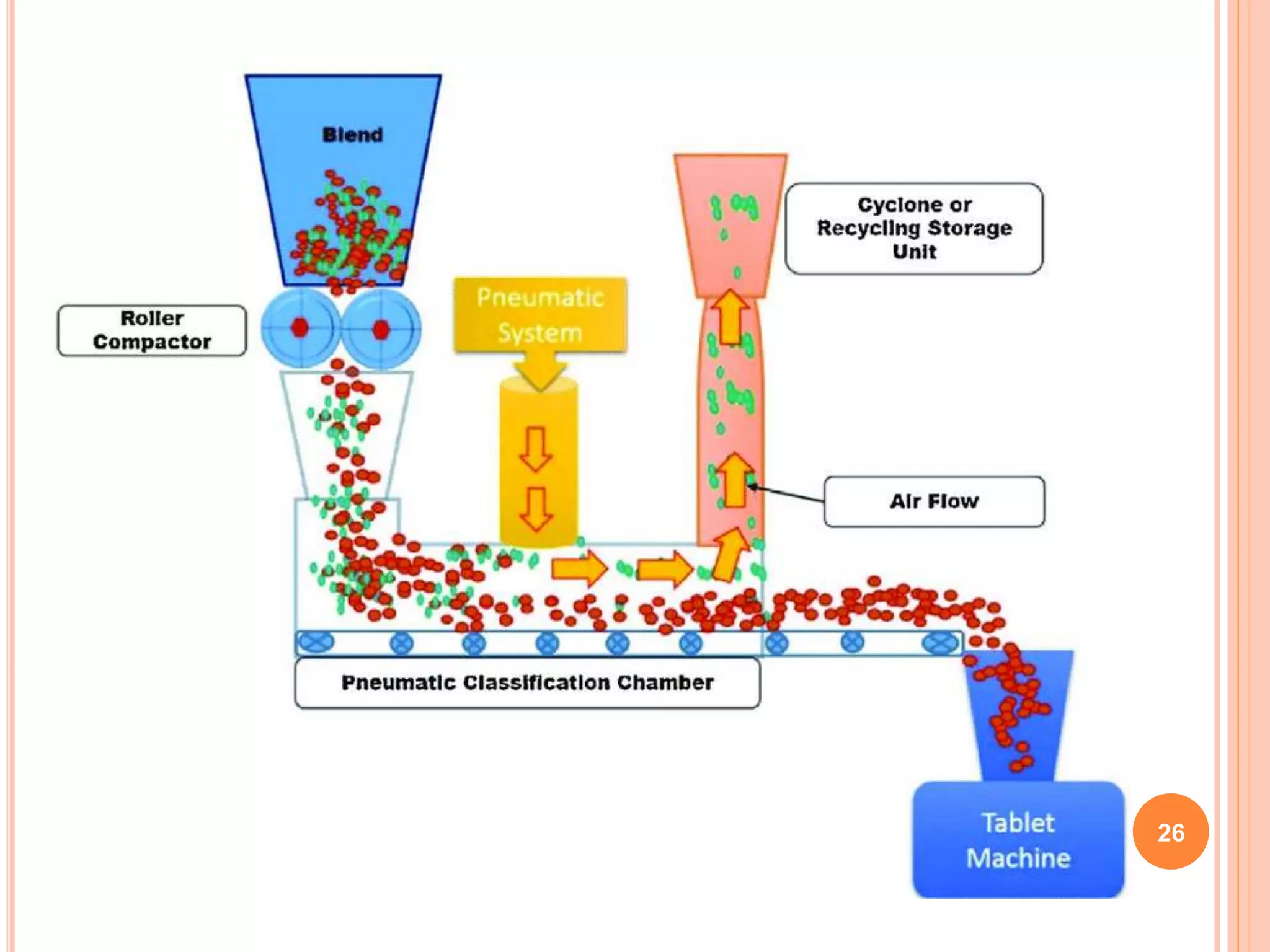

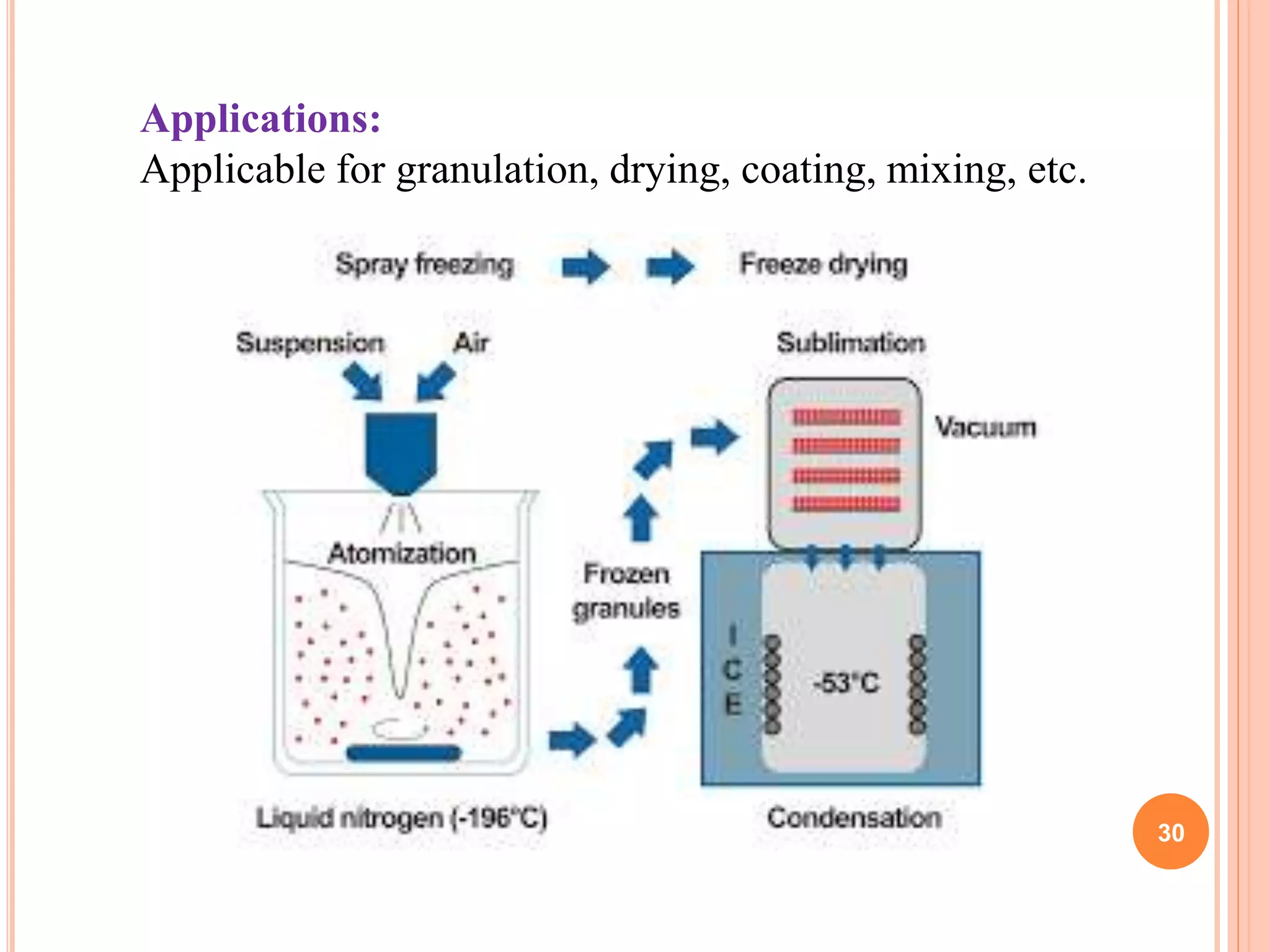

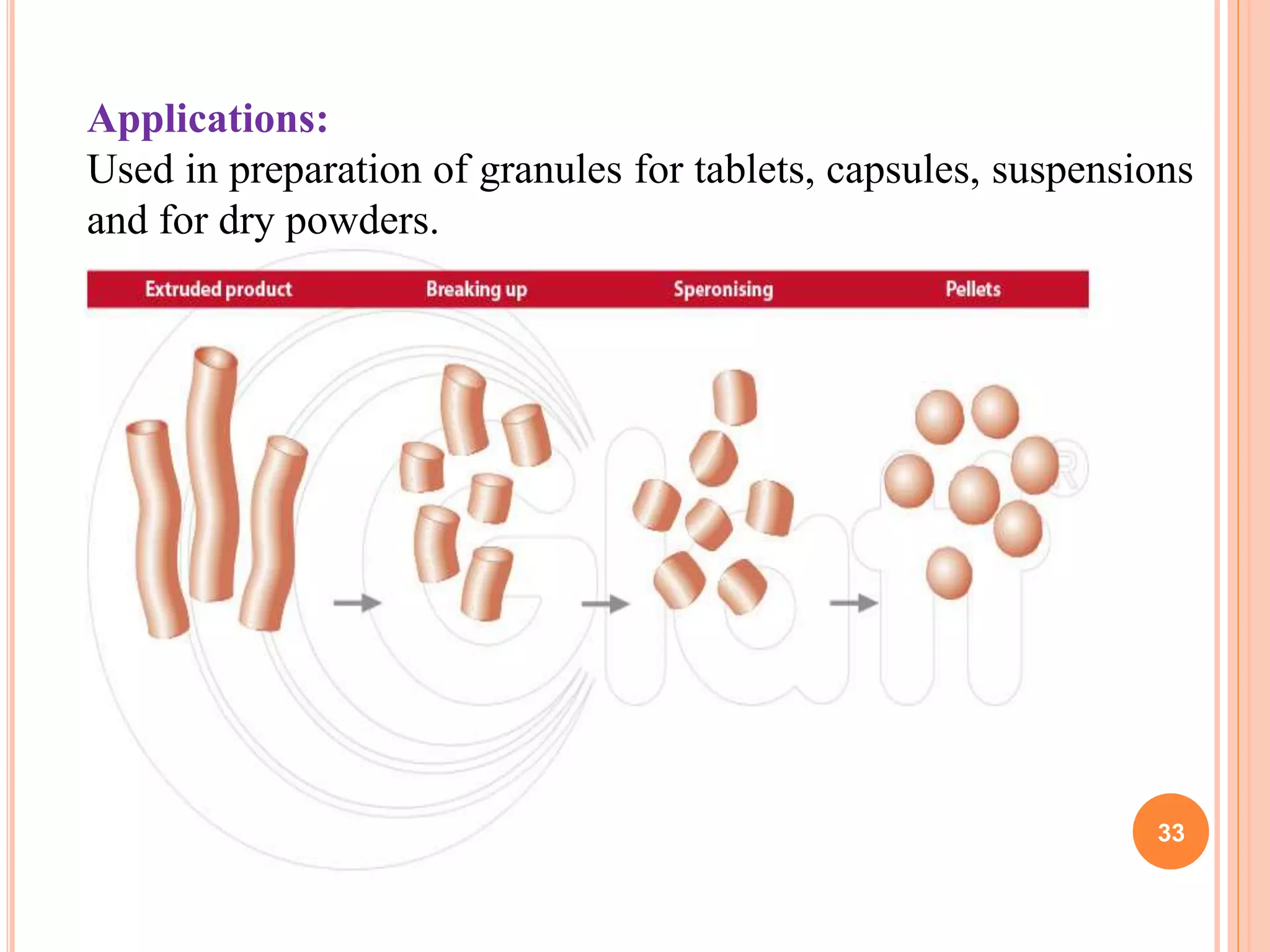

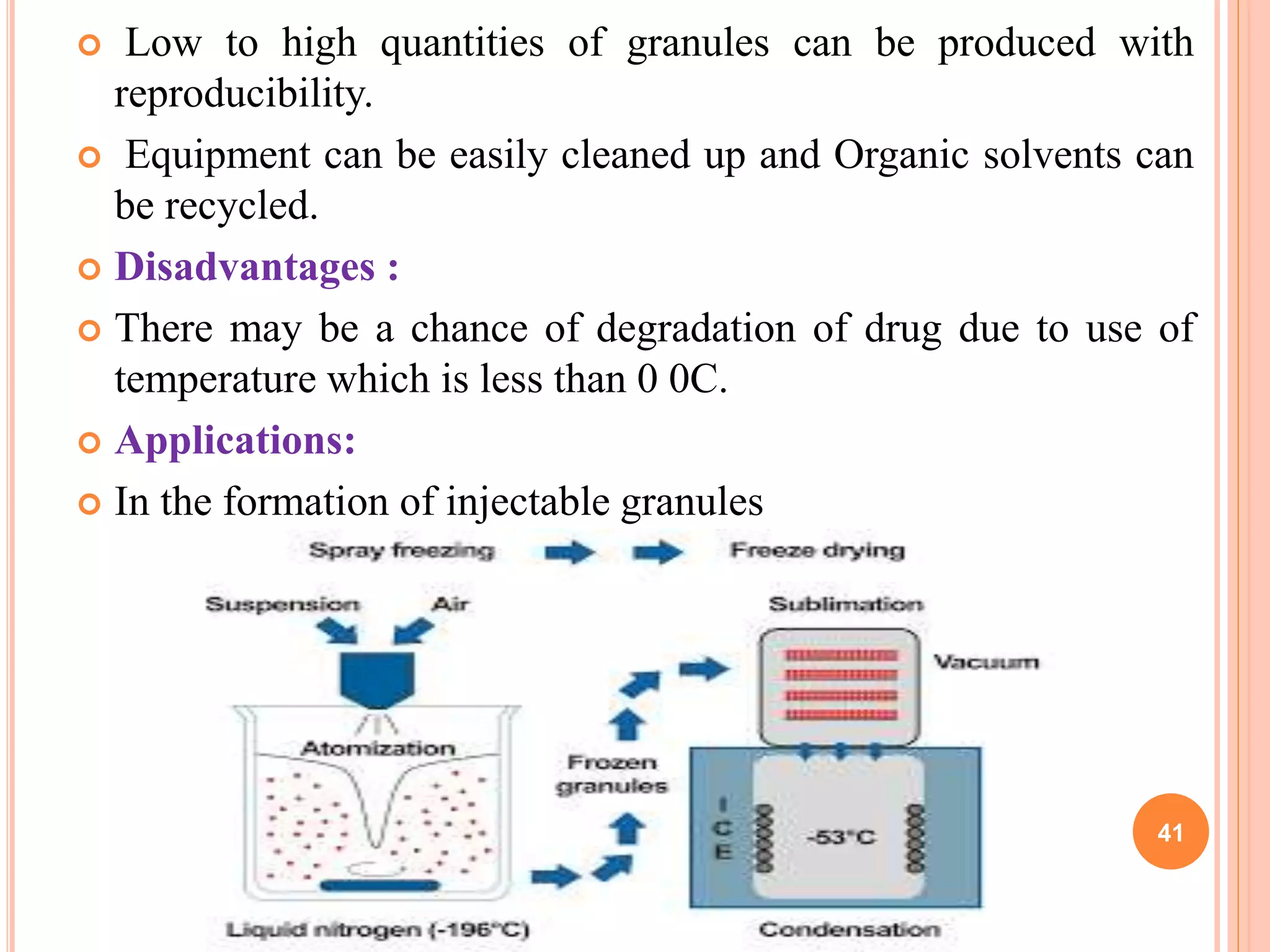

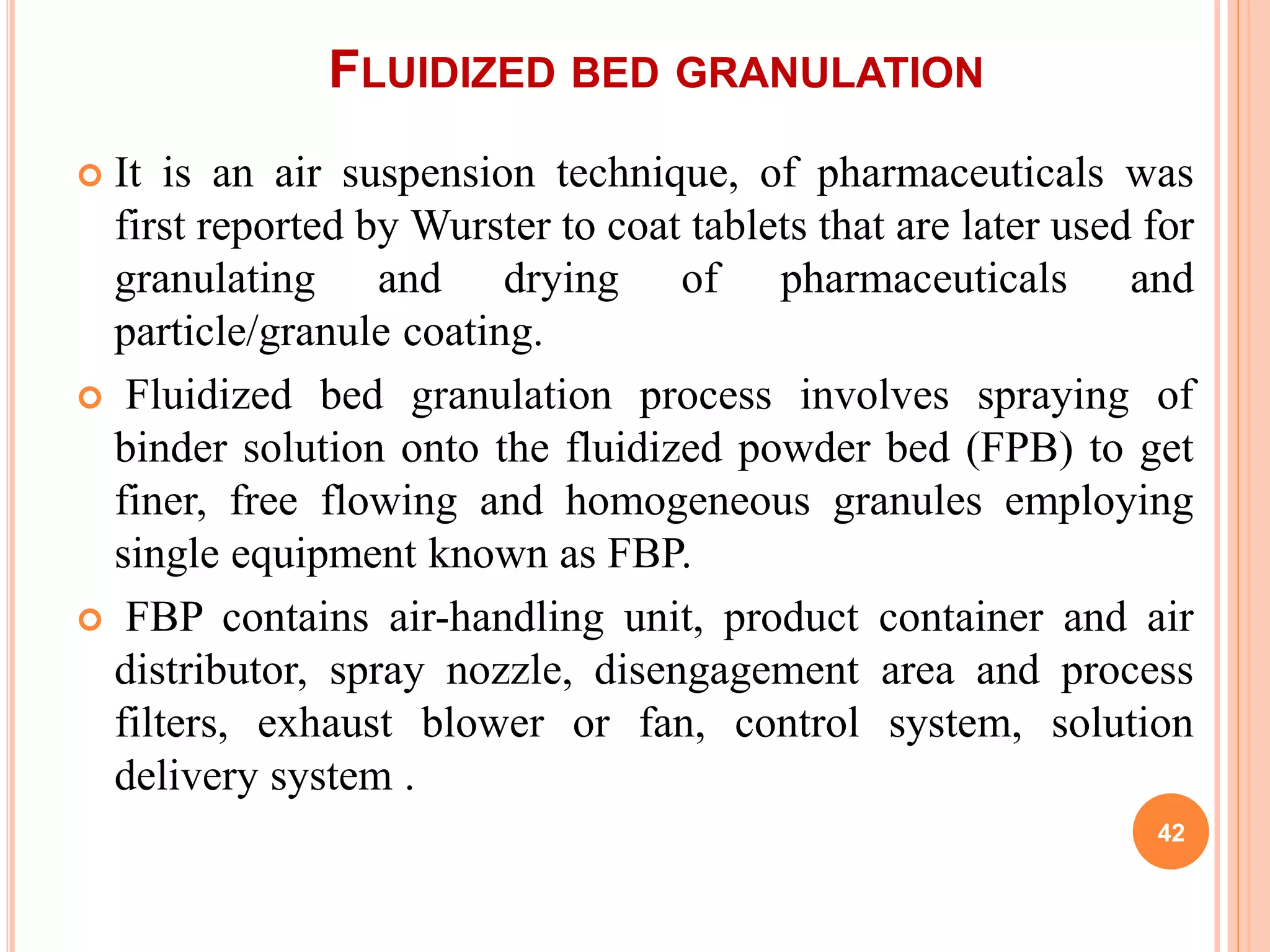

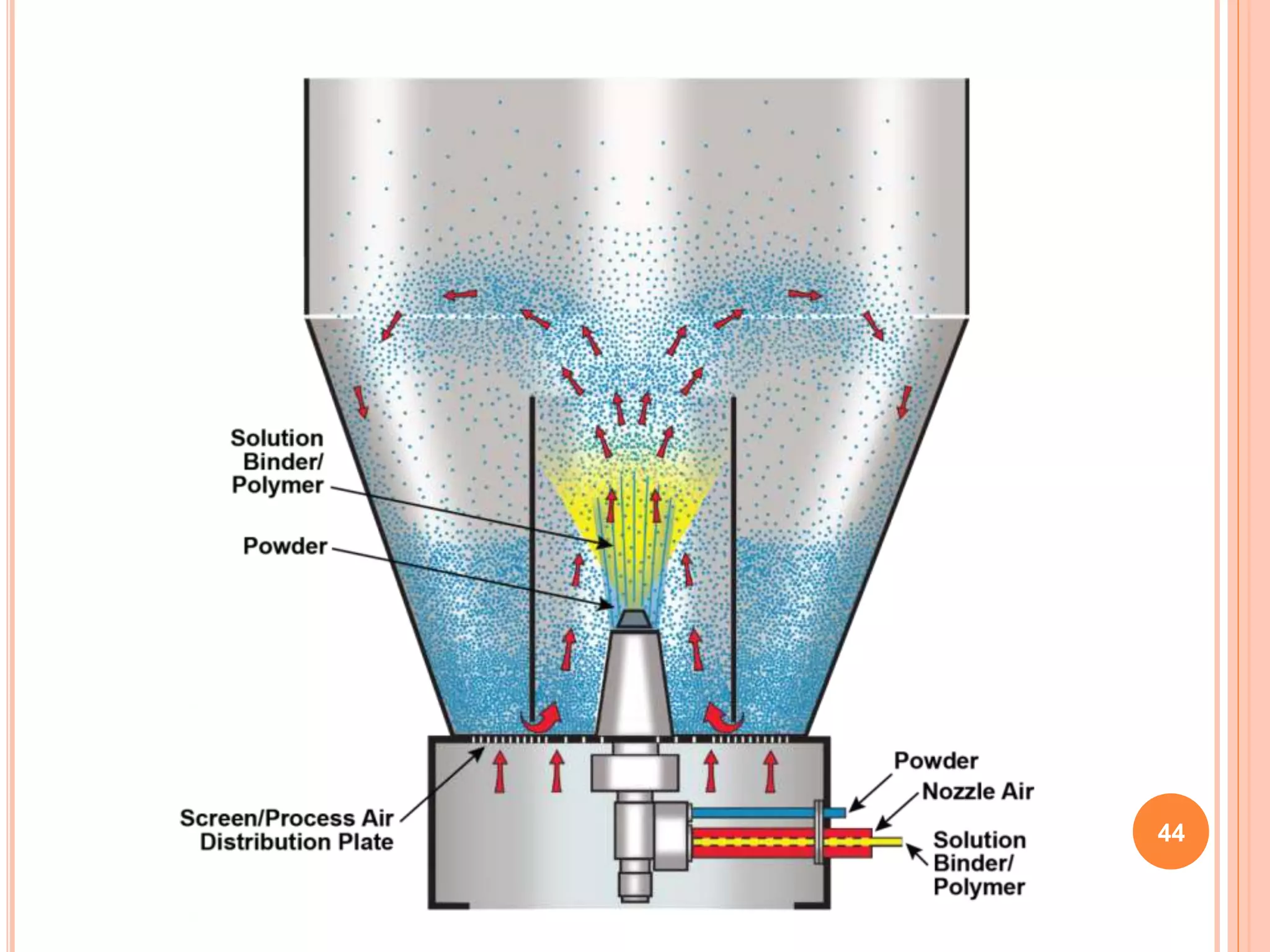

This document provides an overview of granulation techniques used in pharmaceutical manufacturing. It defines granulation and describes common granulation methods like wet and dry granulation. Wet granulation techniques like high shear and low shear mixing are explained in detail along with novel techniques like moisture activated dry granulation, thermal adhesion granulation, and freeze granulation. Key granulation process parameters and characteristics of granules are also summarized. The document concludes by discussing various granulation technologies and their applications in the pharmaceutical industry.