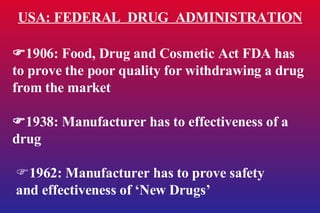

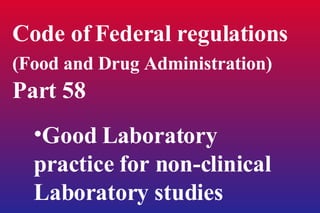

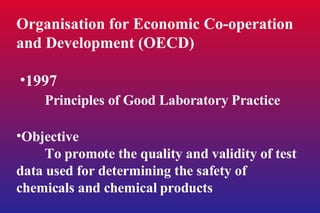

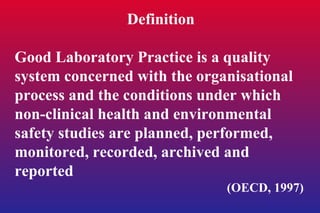

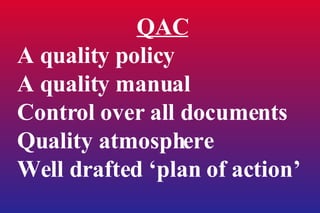

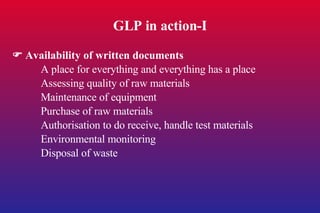

The document discusses Good Laboratory Practice (GLP), which refers to a quality system for non-clinical safety studies. It outlines the history and regulations around GLP from agencies like the FDA and OECD. Key aspects of GLP include establishing a quality assurance unit, appointing a study director, using standard operating procedures and calibrated equipment, qualified personnel, documentation, auditing, and archiving materials. GLP is meant to ensure the quality and validity of non-clinical safety studies.