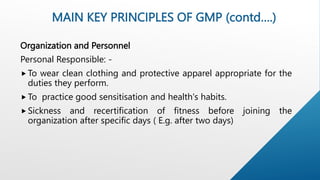

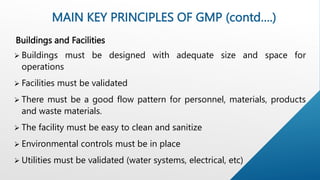

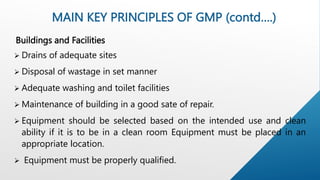

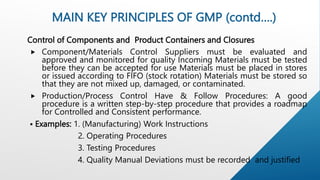

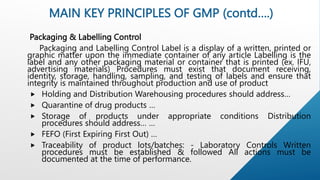

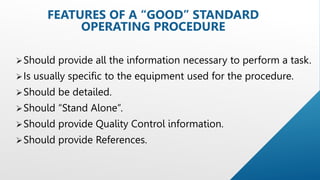

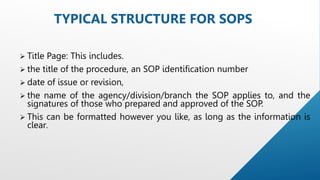

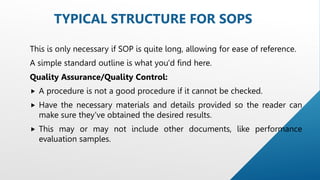

This document discusses Good Manufacturing Practices (GMP) and Standard Operating Procedures (SOPs). It defines GMP as ensuring quality standards in drug production and outlines its main principles, including organization, facilities, equipment, materials control, production processes, packaging, and records. SOPs are defined as written instructions for routine tasks and the document discusses benefits like consistent performance, quality assurance, and training. A typical SOP structure is also outlined.