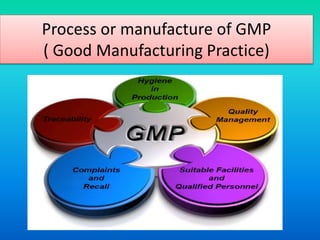

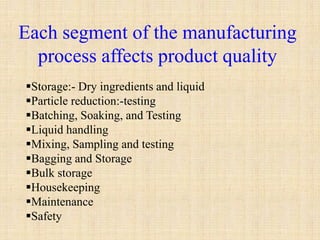

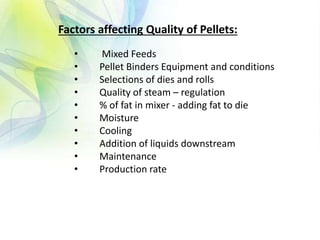

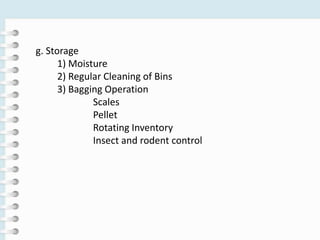

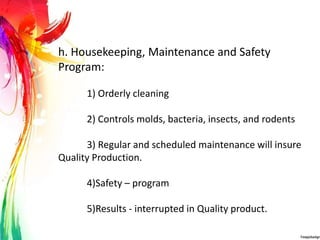

This document outlines the key steps and factors involved in good manufacturing practice for animal feed production. It discusses several segments of the manufacturing process that affect quality, including storage, particle reduction, batching, mixing, pelleting, storage, and housekeeping. For each segment, it identifies specific quality control points such as cleaning, testing, maintenance, and safety practices that ensure a consistent, high-quality end product.