This document provides information on sausage making equipment, processes, safety considerations and sanitation. Key points:

1) Thermometers and scales are critical for ensuring meat and finished product temperatures and ingredient ratios are safe. Sausage is fully cooked at 160°F internally.

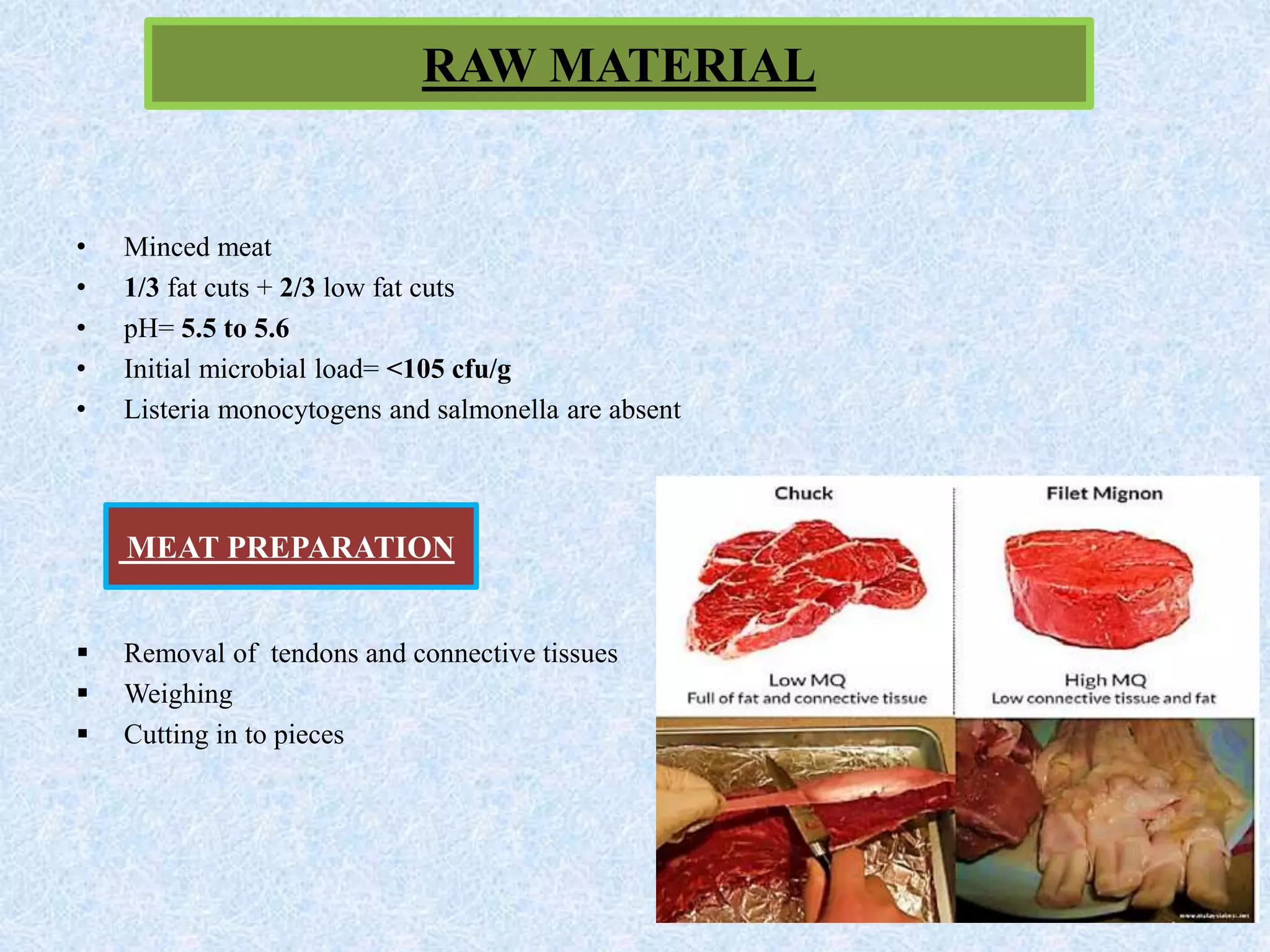

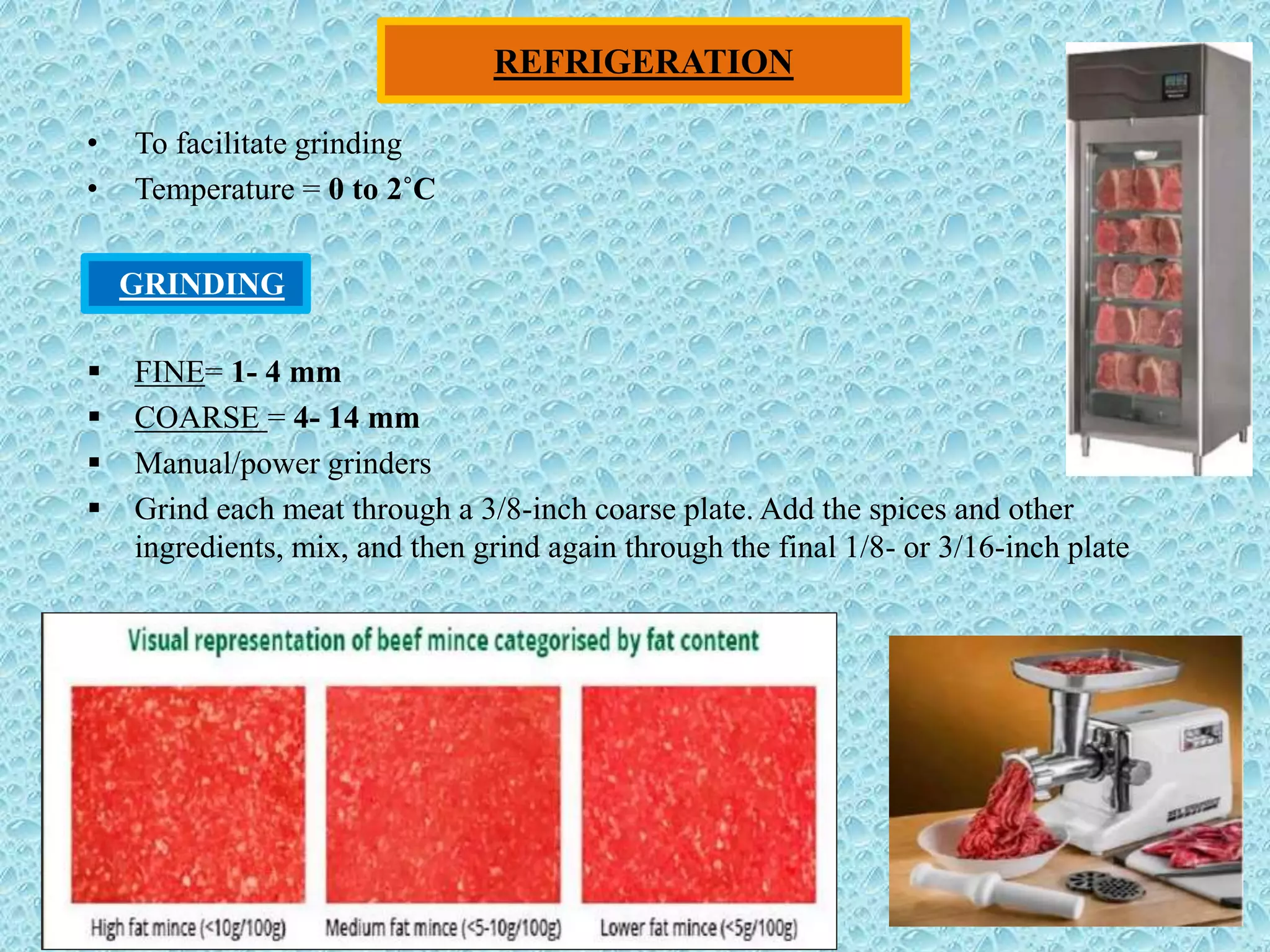

2) Grinders, choppers, stuffers and casings are used to grind, mix, fill and link sausages. Proper grinding plates and sharp blades are important for quality.

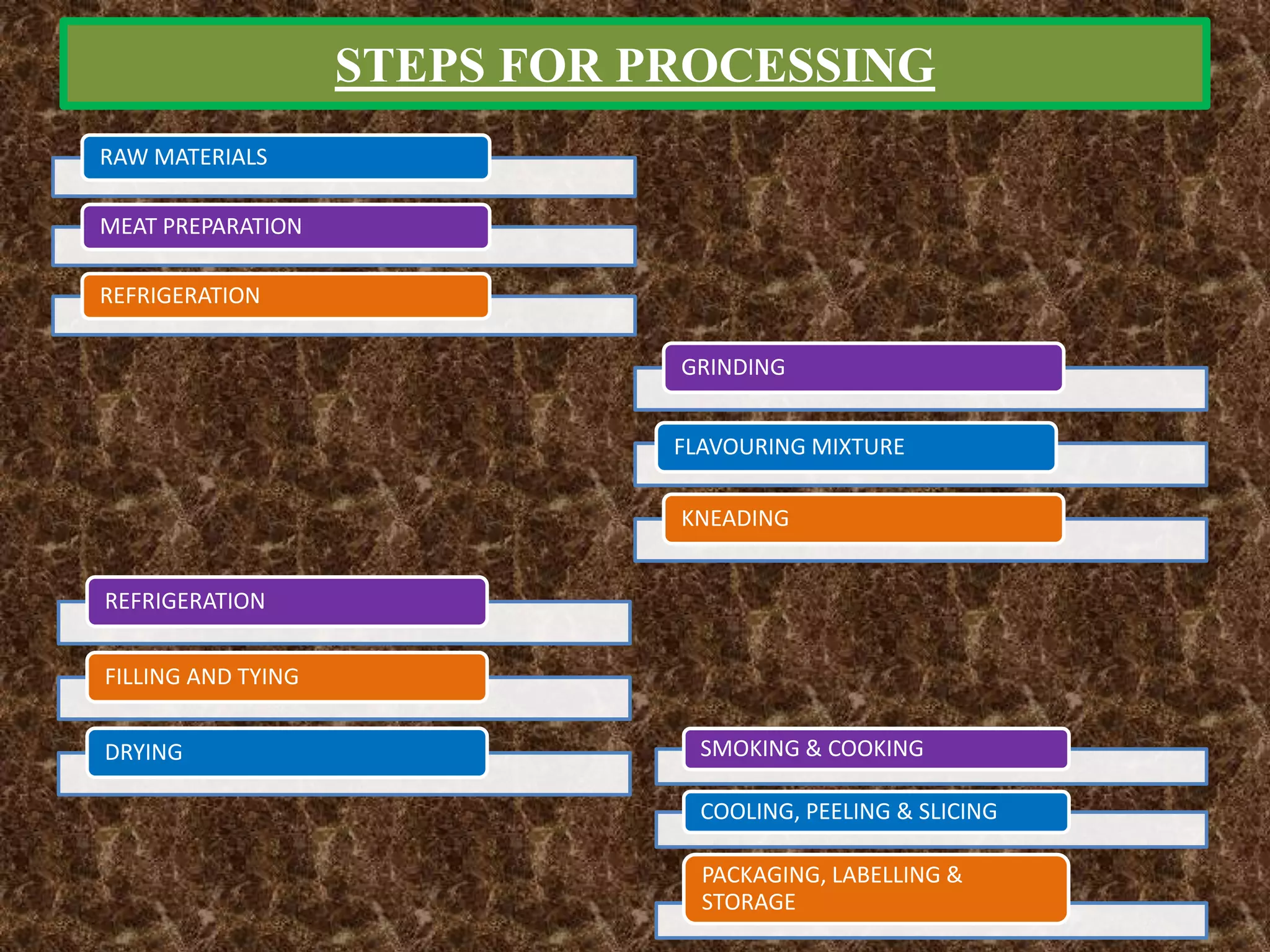

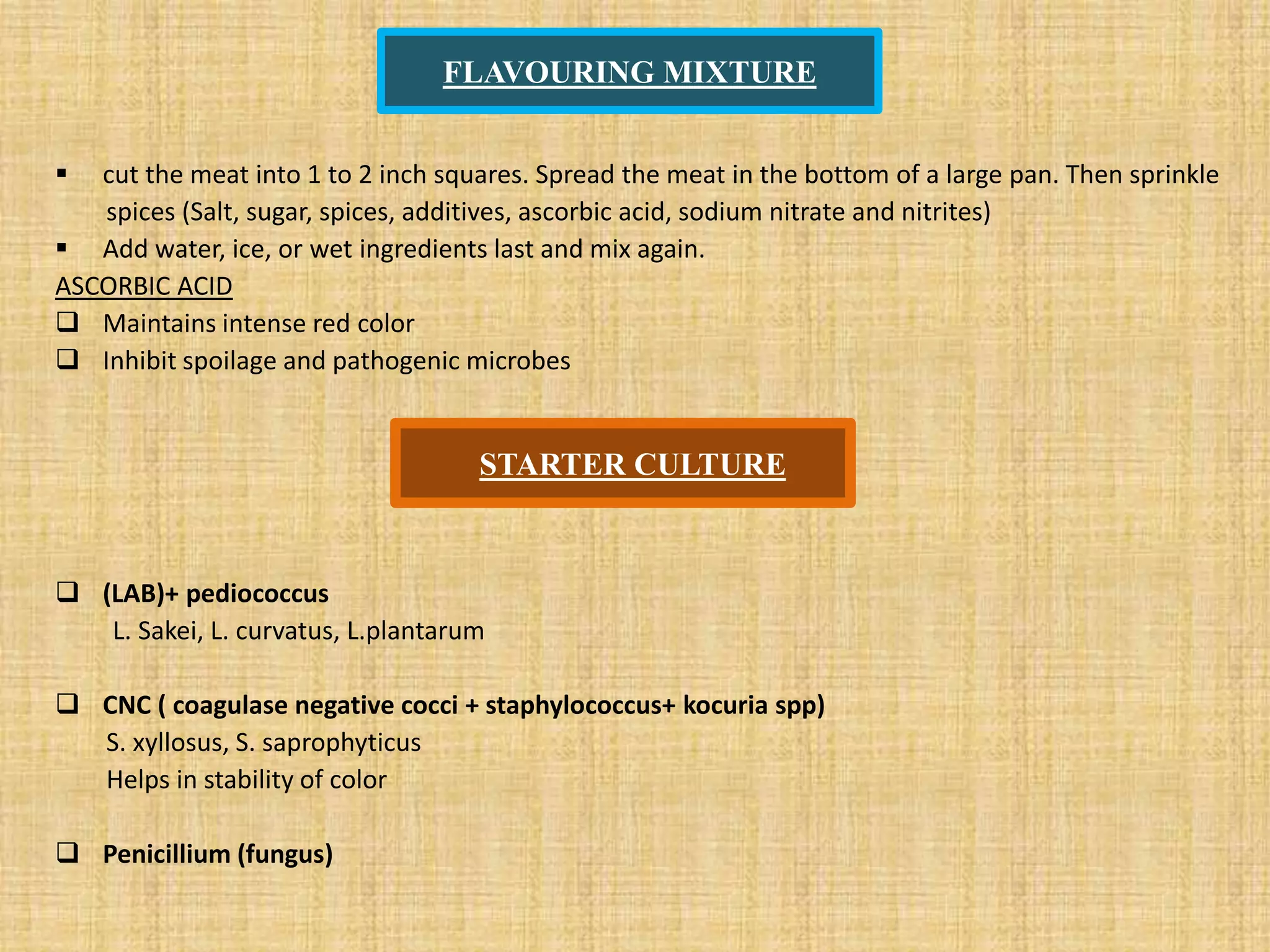

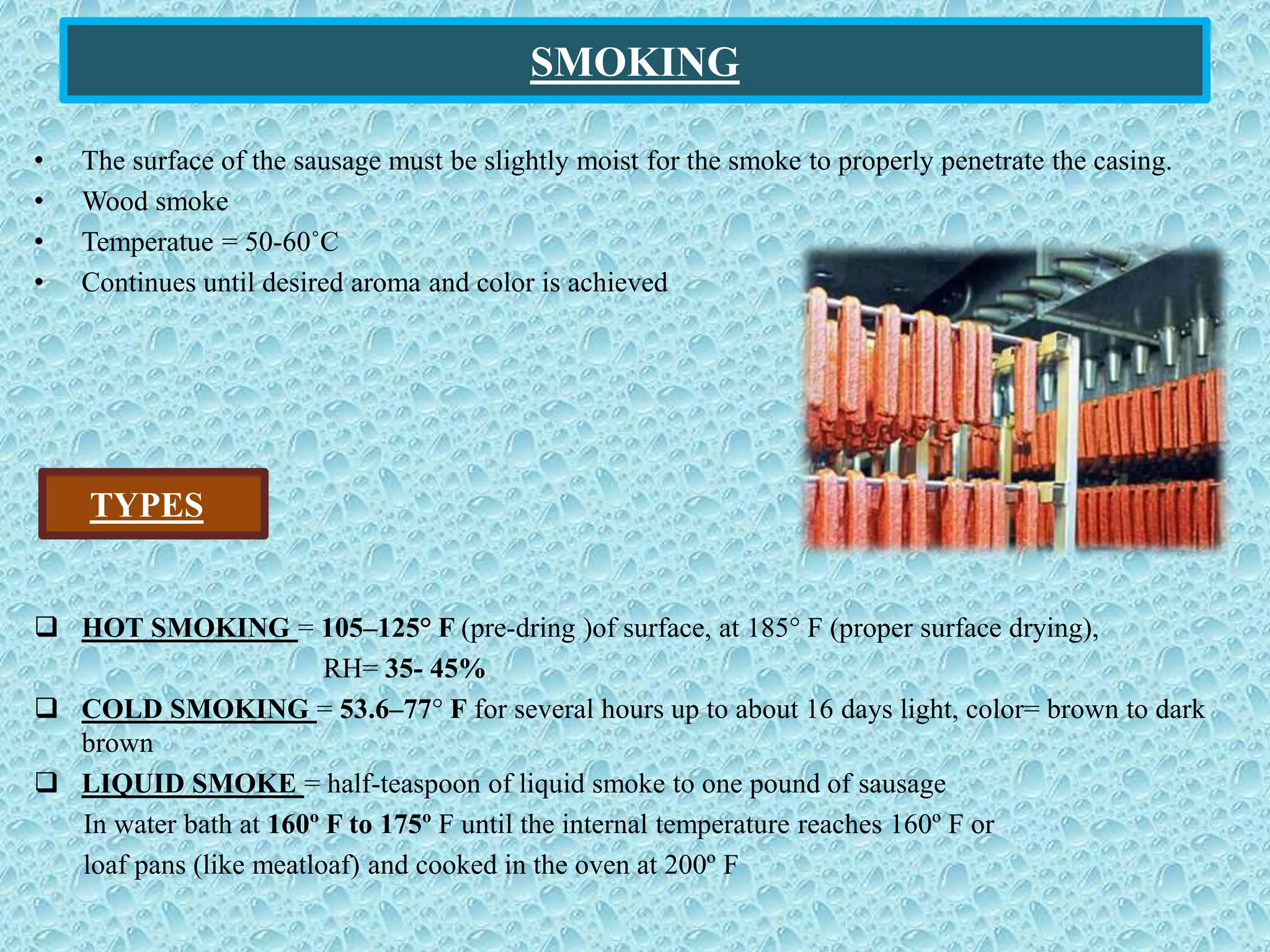

3) Processing involves grinding, mixing spices, stuffing into casings, potential fermentation, drying, smoking and cooking sausages to 160°F. Temperature control and sanitation are essential for safety.

![IMPORTANT CONSIDERATIONS IN SAUSAGE MAKING

Meat products are extremely perishable and must be maintained under refrigeration

(40º F or below).

A calibrated (traced to the National Institute of Standards and Technology [NIST] standard)

thermometer is necessary to ensuring that raw meat and meat ingredients do not exceed 40°

After the product has been formulated, smoke and cook it to the required temperature, and then

return the product to refrigeration.

1) TEMPERATURE](https://image.slidesharecdn.com/processingofsausages-210811155811/75/PROCESSING-OF-SAUSAGES-16-2048.jpg)