The document discusses food safety practices and Good Manufacturing Practices (GMPs). It covers topics like basic food safety, food handling practices, GMPs, and employee hygiene. The key points are:

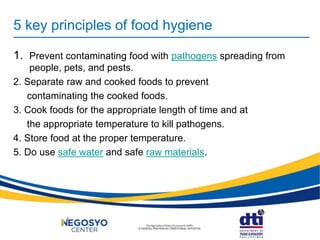

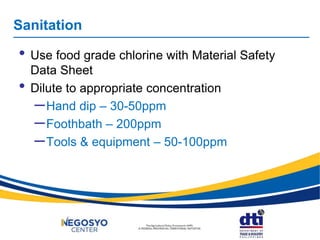

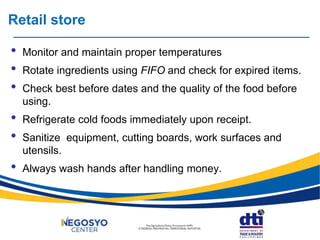

1) Food safety aims to prevent foodborne illness during handling, preparation, and storage of food. Proper hygiene and sanitation standards are important.

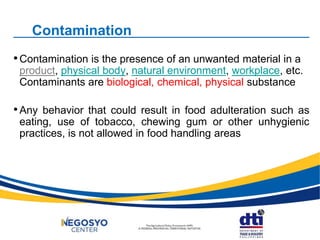

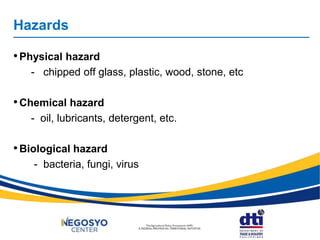

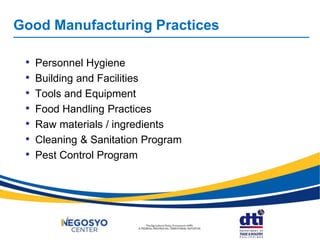

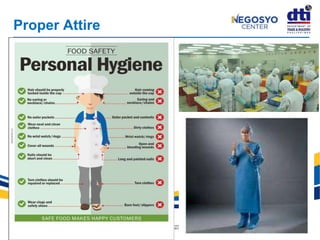

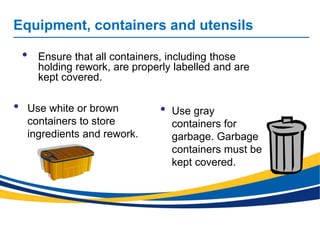

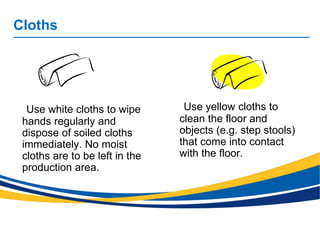

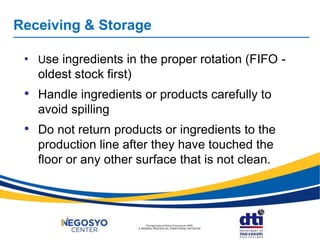

2) GMPs are activities and practices that prevent hazards and contamination in food production. They address issues like personnel hygiene, facilities, equipment cleaning, and receiving/storage.

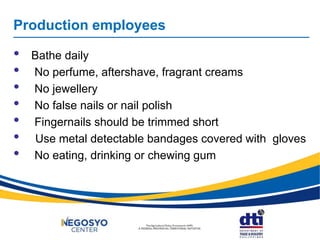

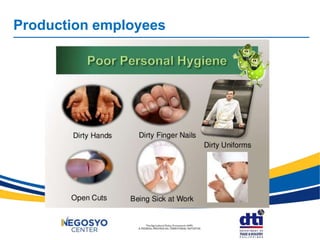

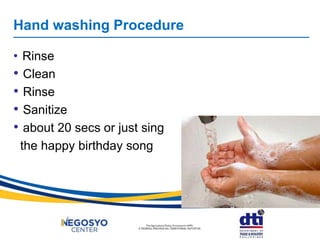

3) Employee hygiene practices include proper protective attire, handwashing, illness reporting, and ensuring cuts/wounds are covered. Personnel must