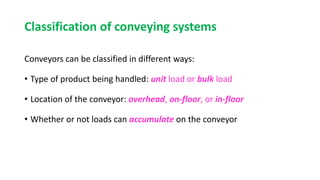

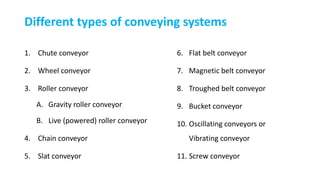

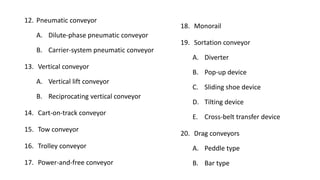

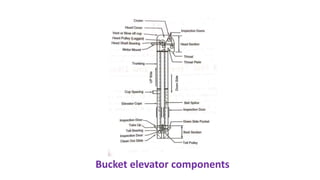

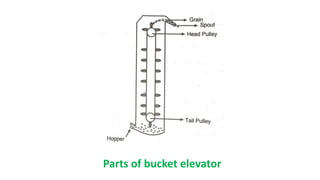

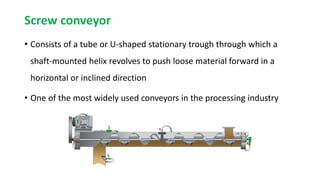

The document provides an overview of various conveying systems commonly used in feed mills, detailing their classifications and functions. Key types include chute, wheel, roller, chain, and bucket conveyors, each with specific applications and mechanisms for material transportation. Additionally, it covers advanced systems like pneumatic and sortation conveyors that enhance efficiency in handling bulk materials.