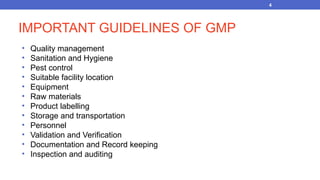

The document outlines the significance of Good Manufacturing Practices (GMP) and Hazard Analysis and Critical Control Points (HACCP) in the meat processing industry, emphasizing their roles in ensuring food safety and product quality. It discusses the necessity of employee training, regular monitoring, and audits to comply with these standards, alongside the integration of both systems for optimal results. The conclusion highlights a commitment to food safety and the potential for technological advancements to enhance the quality of meat products.