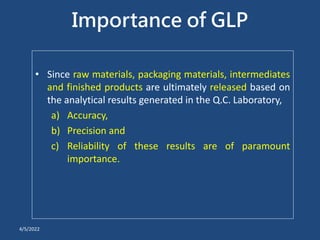

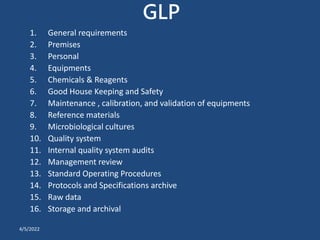

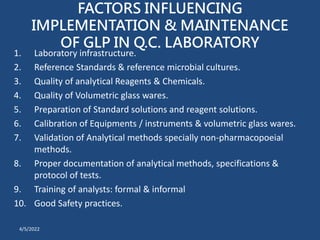

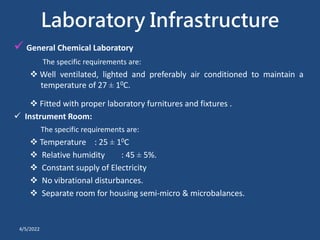

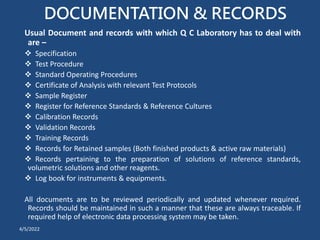

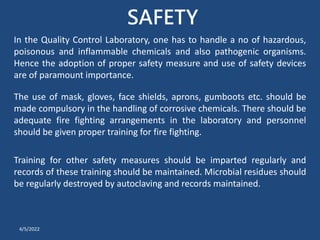

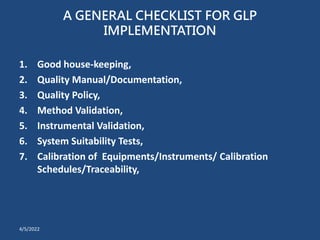

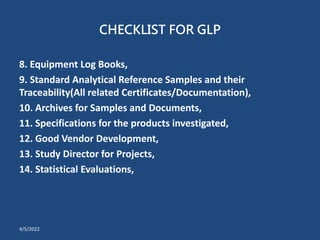

This document discusses Good Laboratory Practices (GLP) for quality control laboratories. It defines GLP as a quality system for non-clinical health and environmental safety studies. The purpose of GLP is to promote valid and quality test data for determining safety. Key aspects of GLP include infrastructure requirements for different laboratory sections, calibration and validation of equipment, documentation standards, training programs, and safety measures. The document also provides checklists to ensure all GLP requirements are properly implemented and maintained in the quality control laboratory.