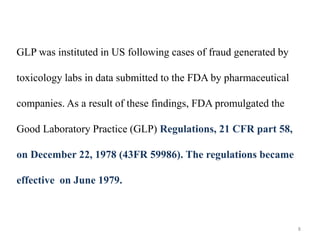

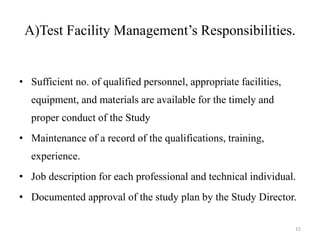

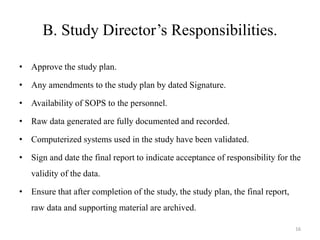

This document provides an overview of Good Laboratory Practice (GLP) principles established by the Organization for Economic Co-operation and Development (OECD). GLP was created in response to cases of fraudulent laboratory practices and aims to ensure the quality and validity of non-clinical safety studies. The key principles include requirements for test facility organization, quality assurance programs, facilities, equipment, test systems, test items, standard operating procedures, study conduct, reporting, and record keeping. Following GLP aims to yield data that accurately reflect study results and ensure international acceptance of safety tests.