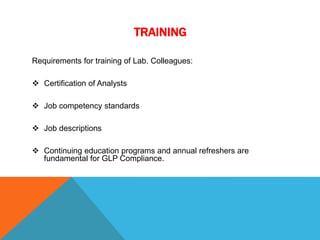

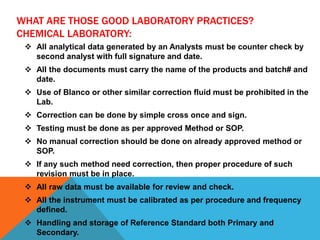

Good Laboratory Practices (GLP) are a set of principles that provide a framework for the organization and quality processes of laboratories conducting studies on products that are regulated. GLP helps ensure safety, quality and uniformity of pharmaceutical products by requiring laboratories to implement standards for areas like documentation, training, equipment validation, and safety. Key aspects of GLP include establishing standard operating procedures, maintaining accurate records, ensuring only authorized personnel and properly labeled materials are in laboratories, and providing training to laboratory staff. Following GLP principles improves the performance and effectiveness of quality control in laboratories.