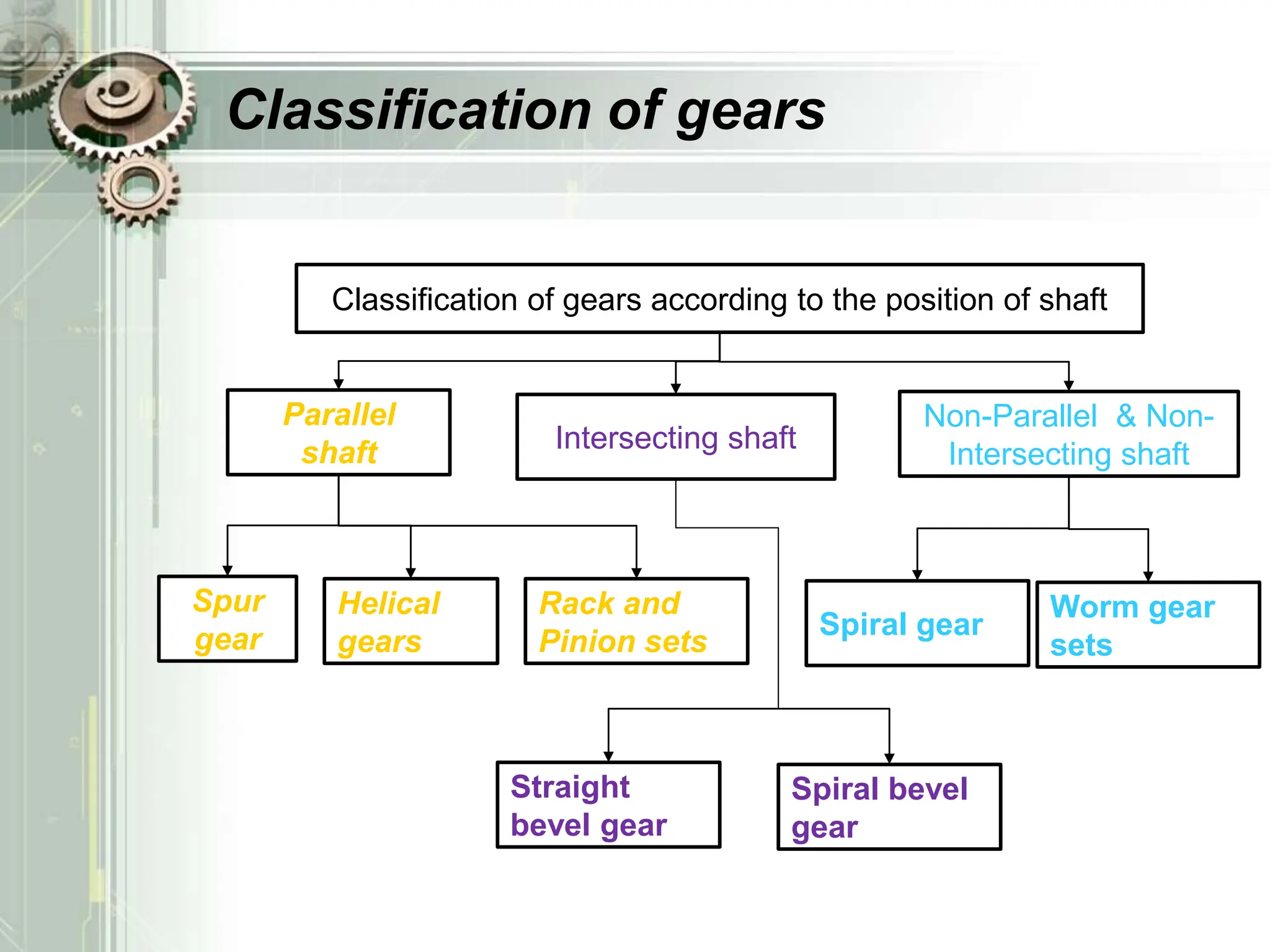

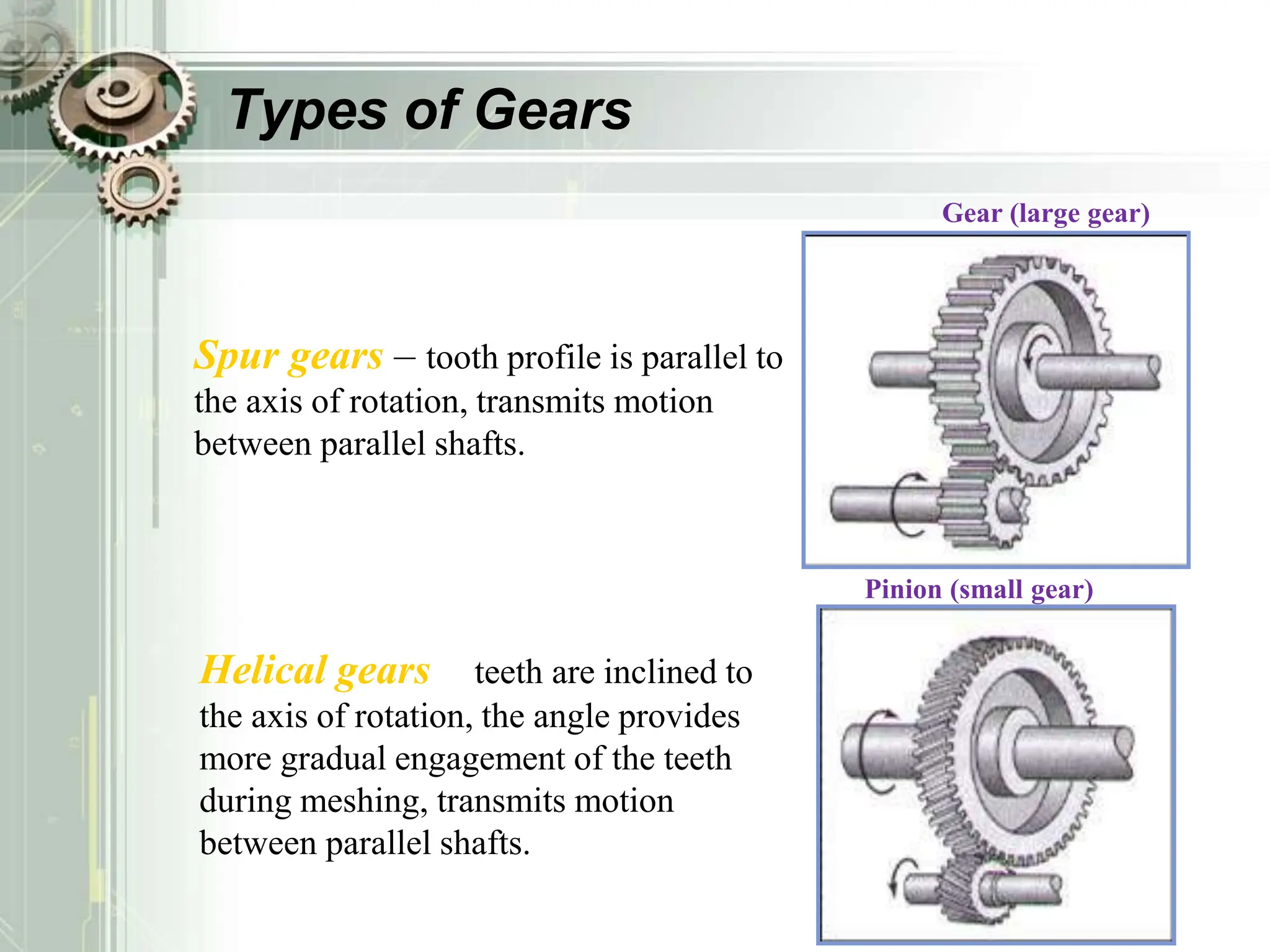

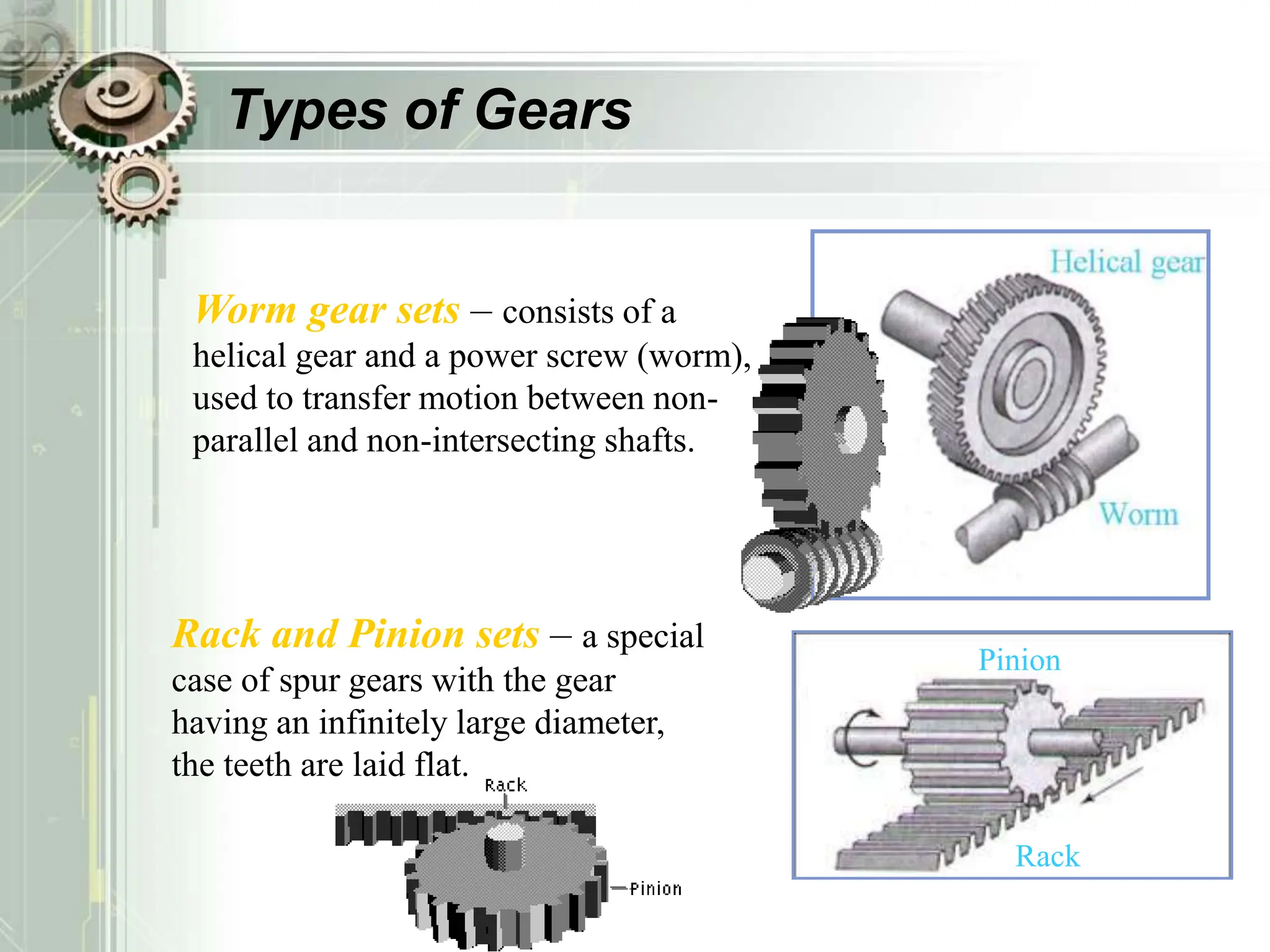

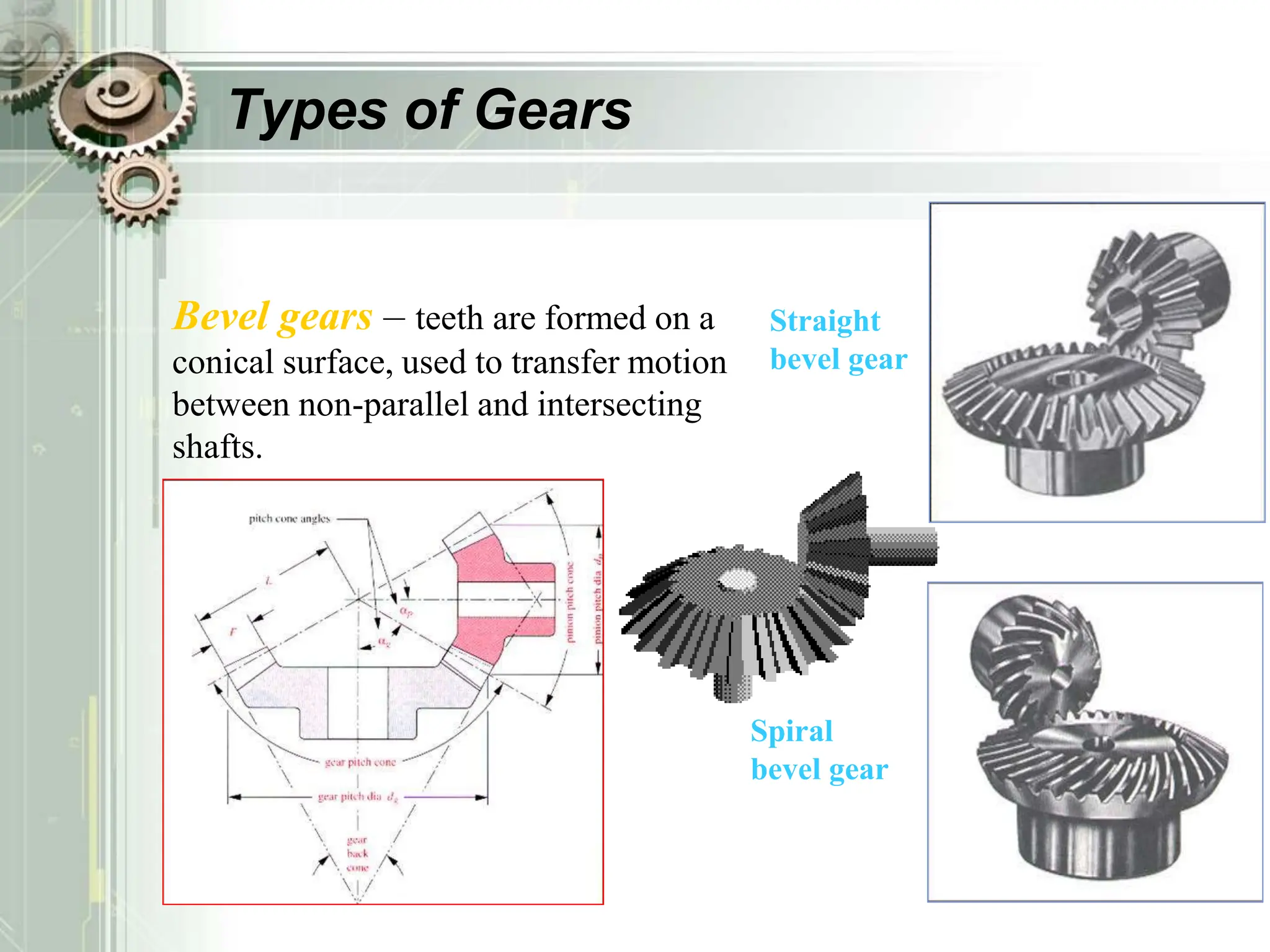

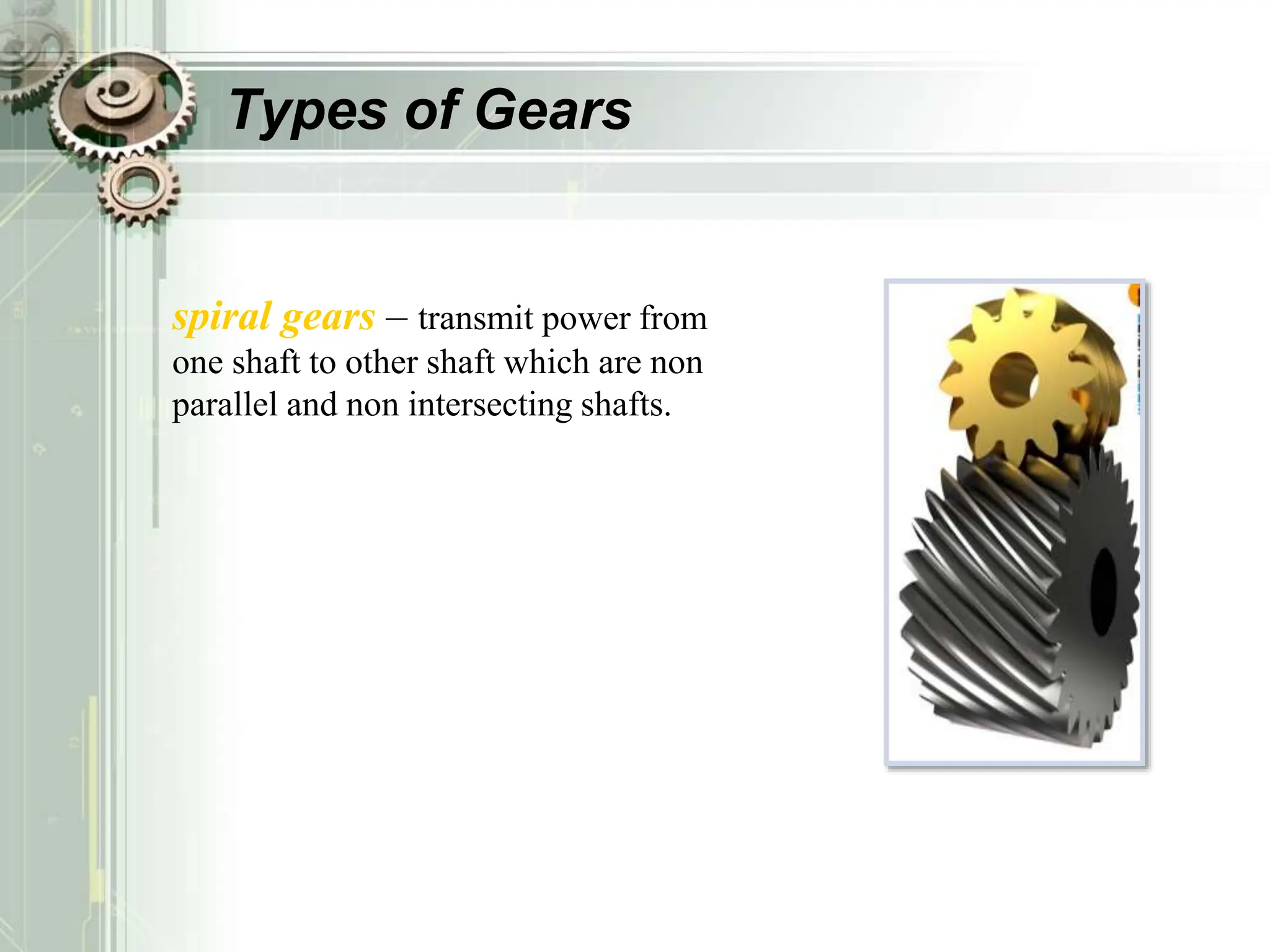

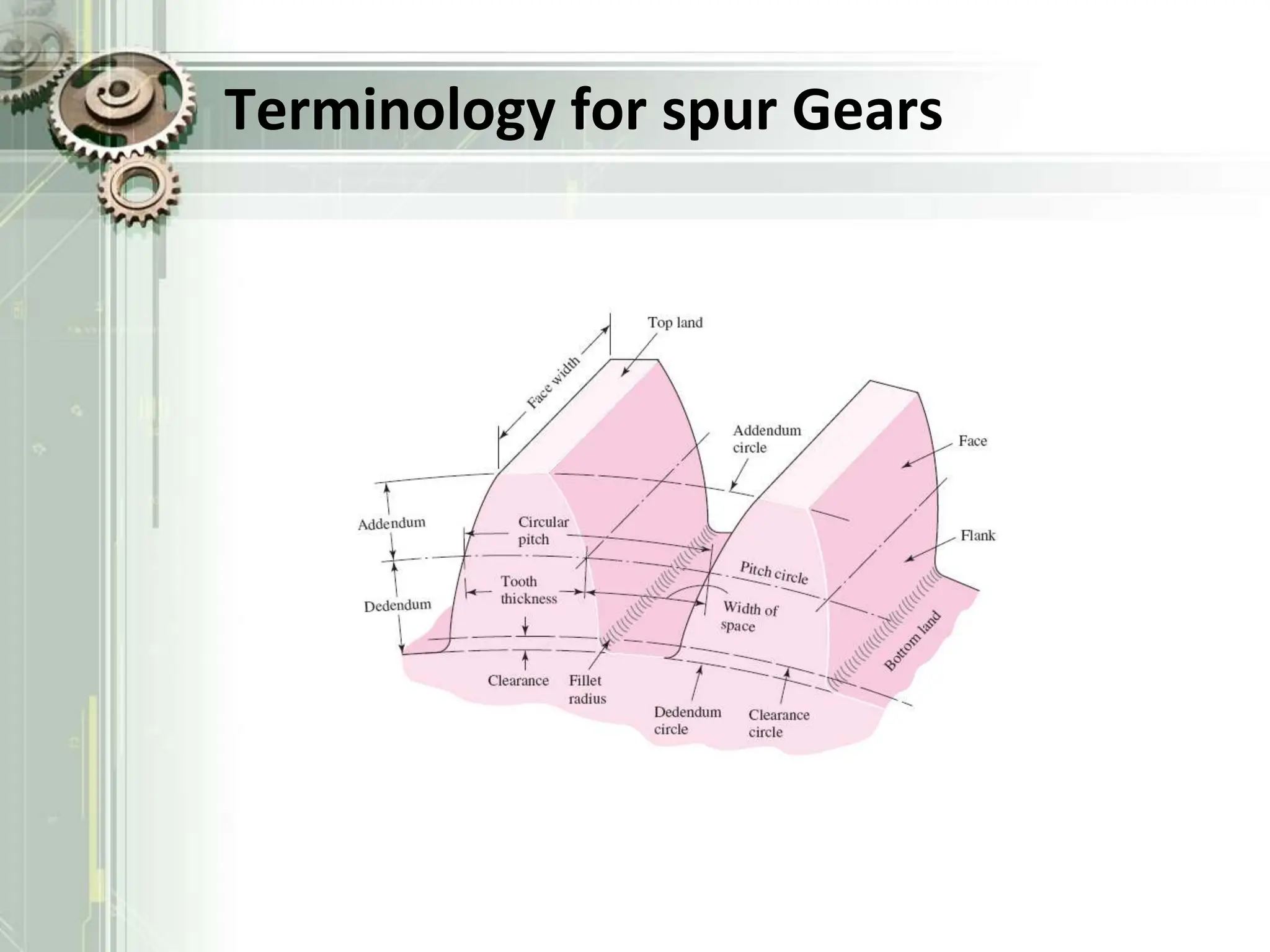

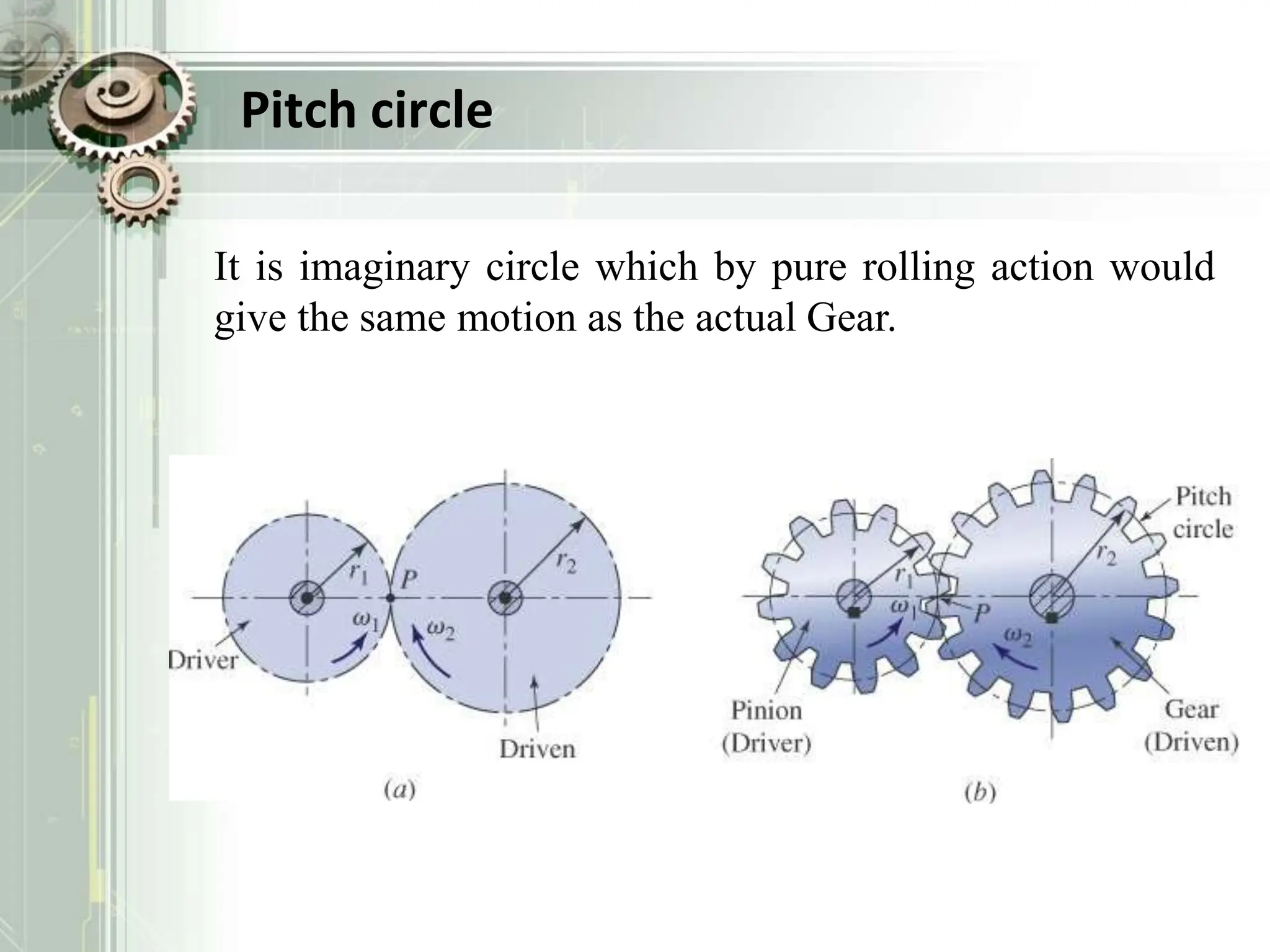

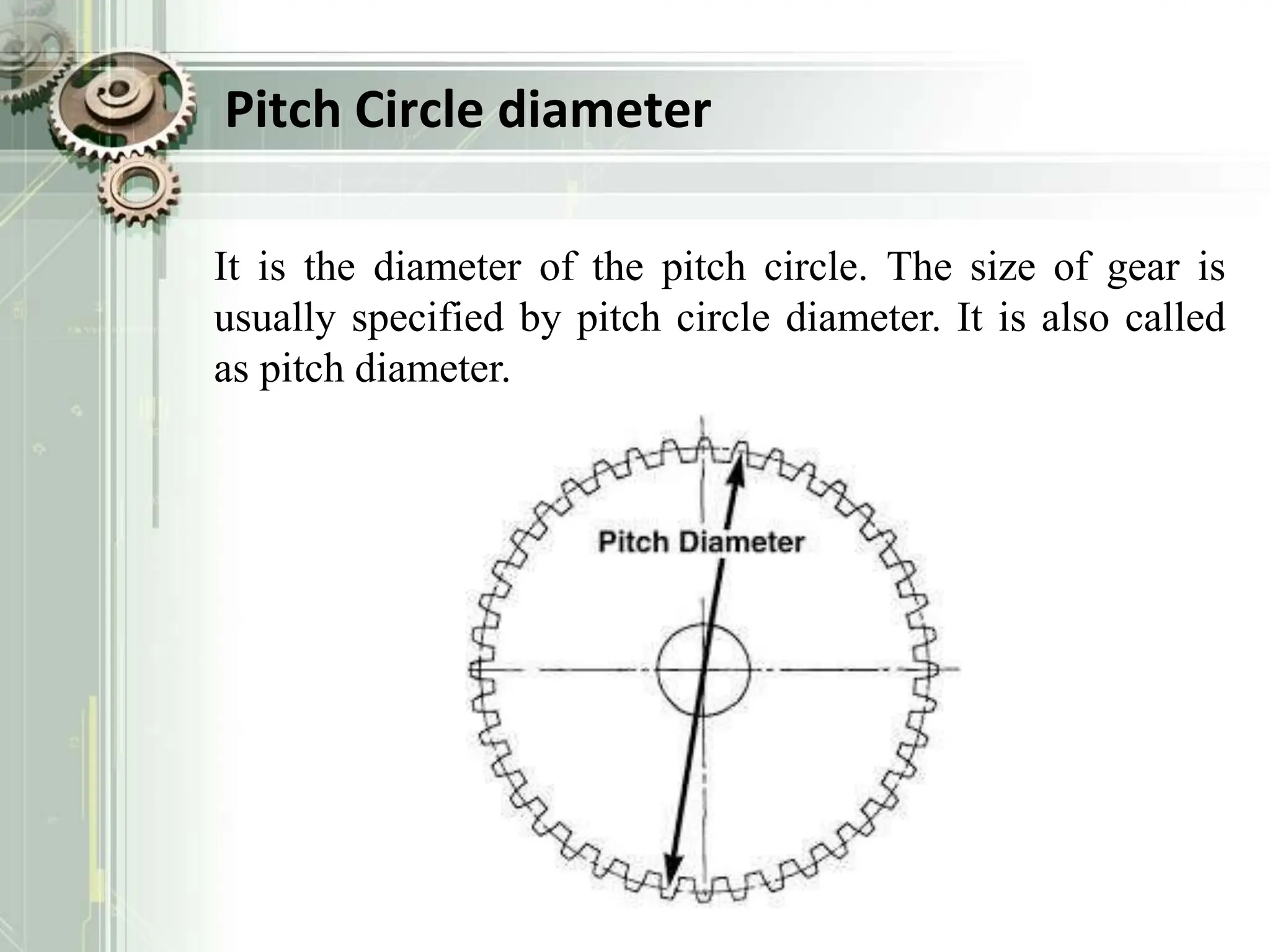

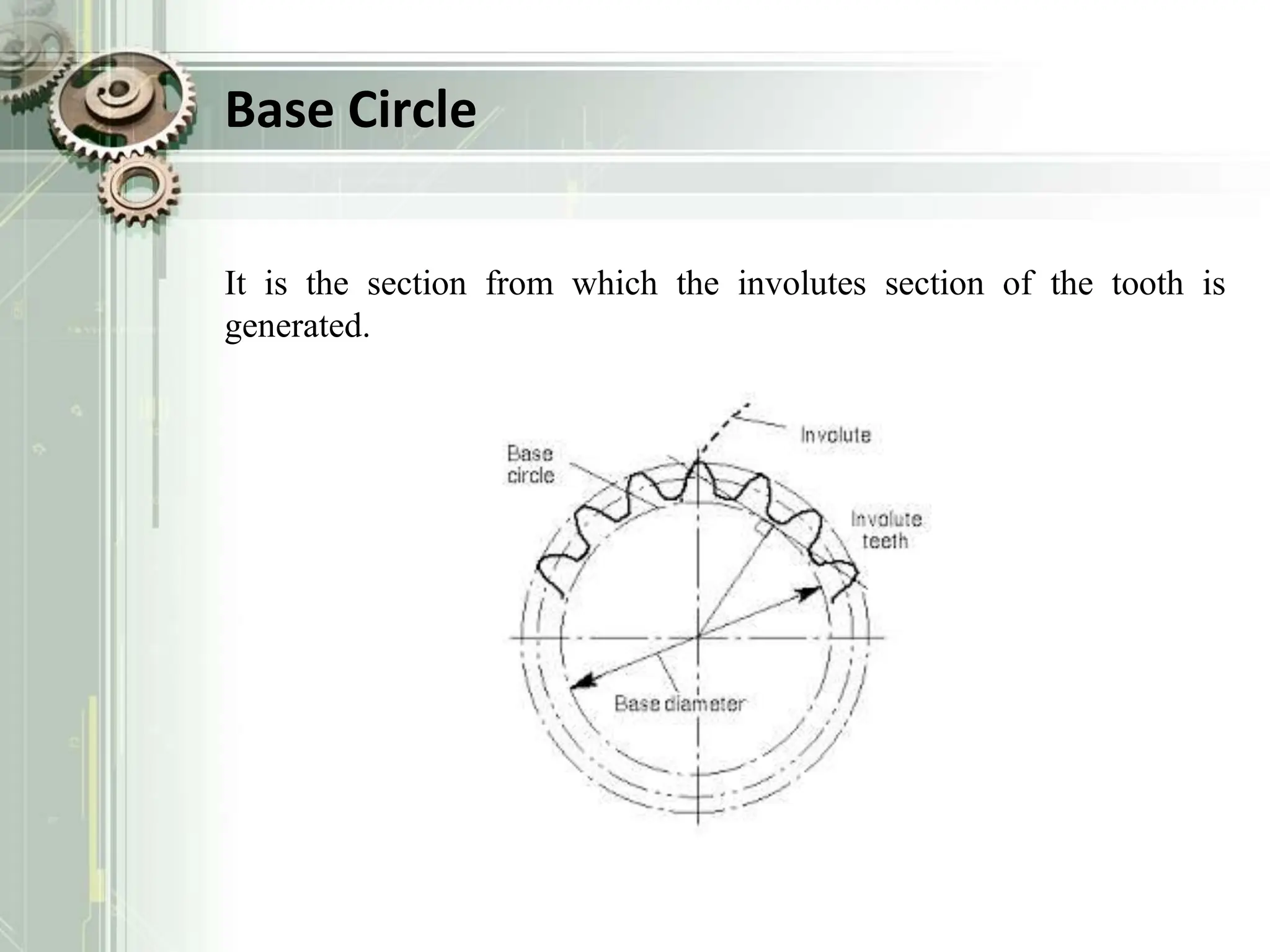

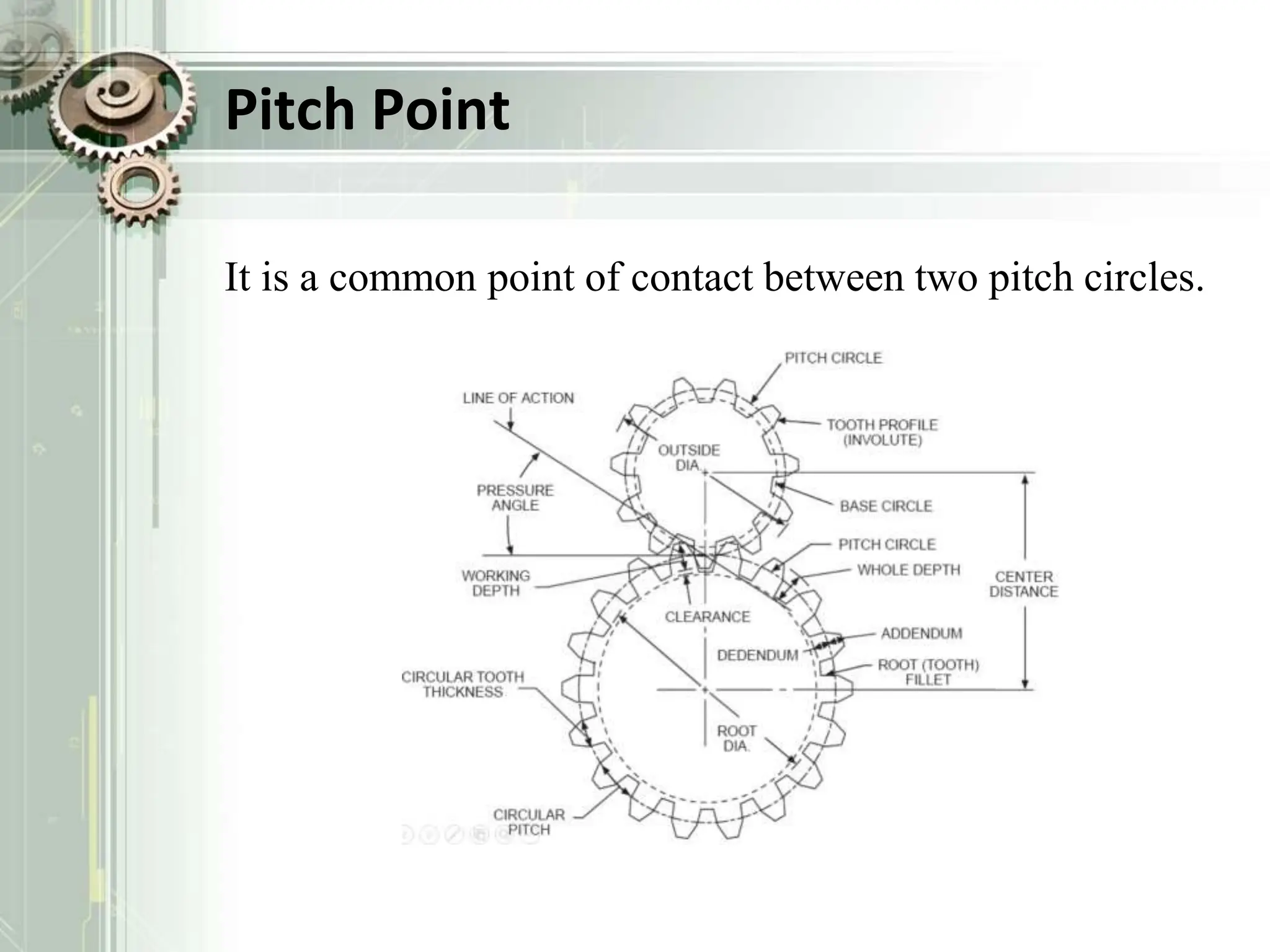

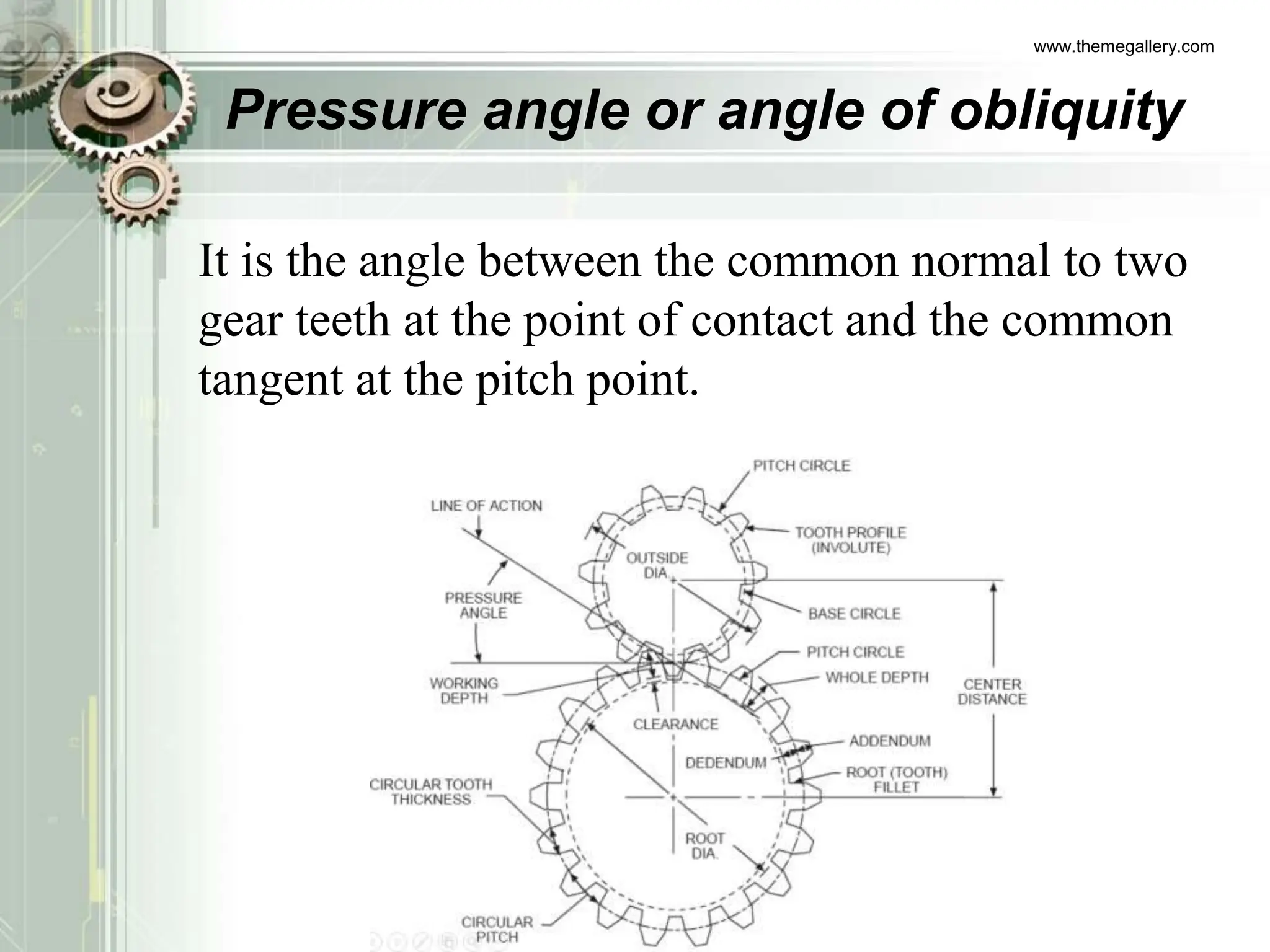

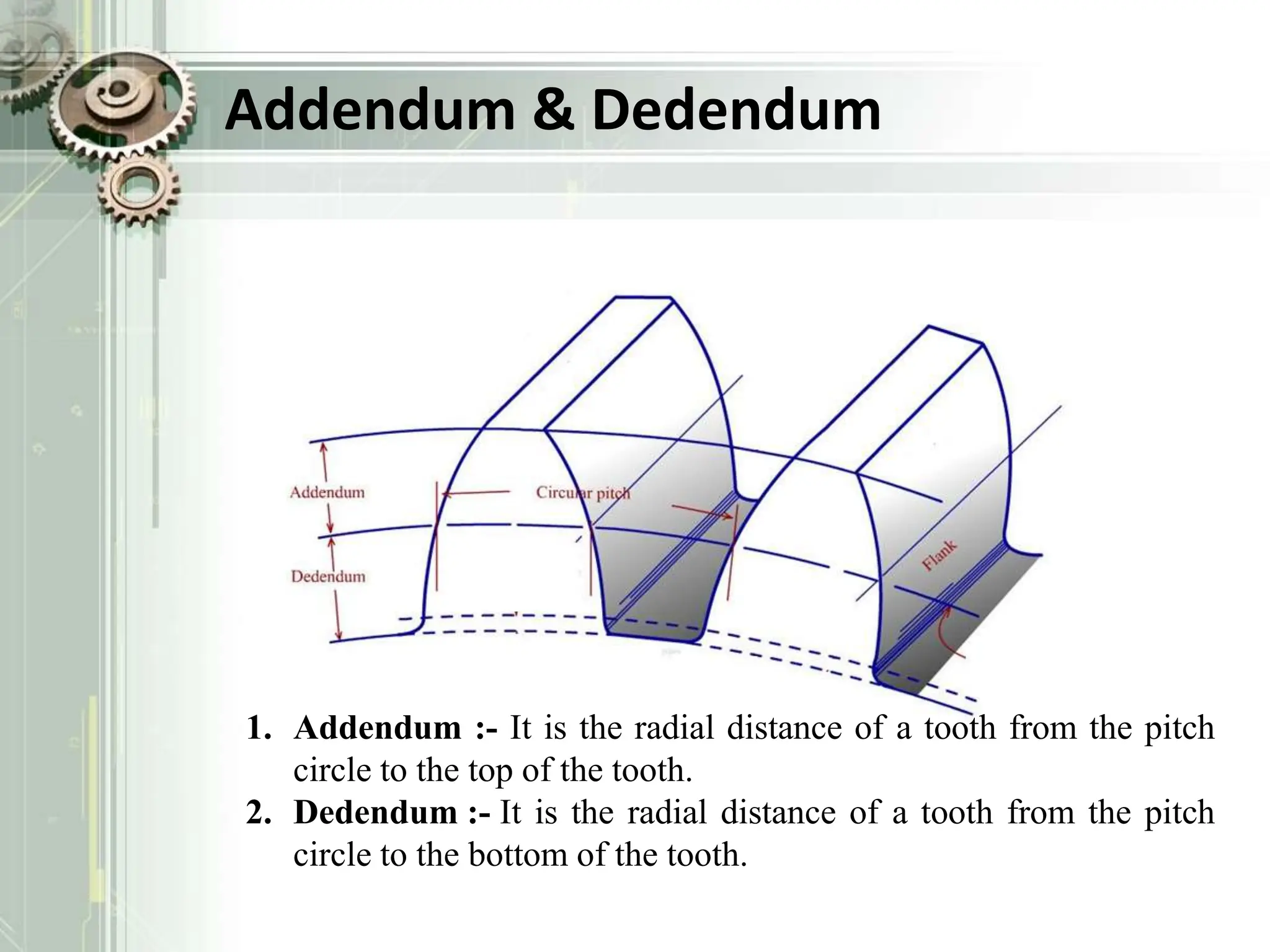

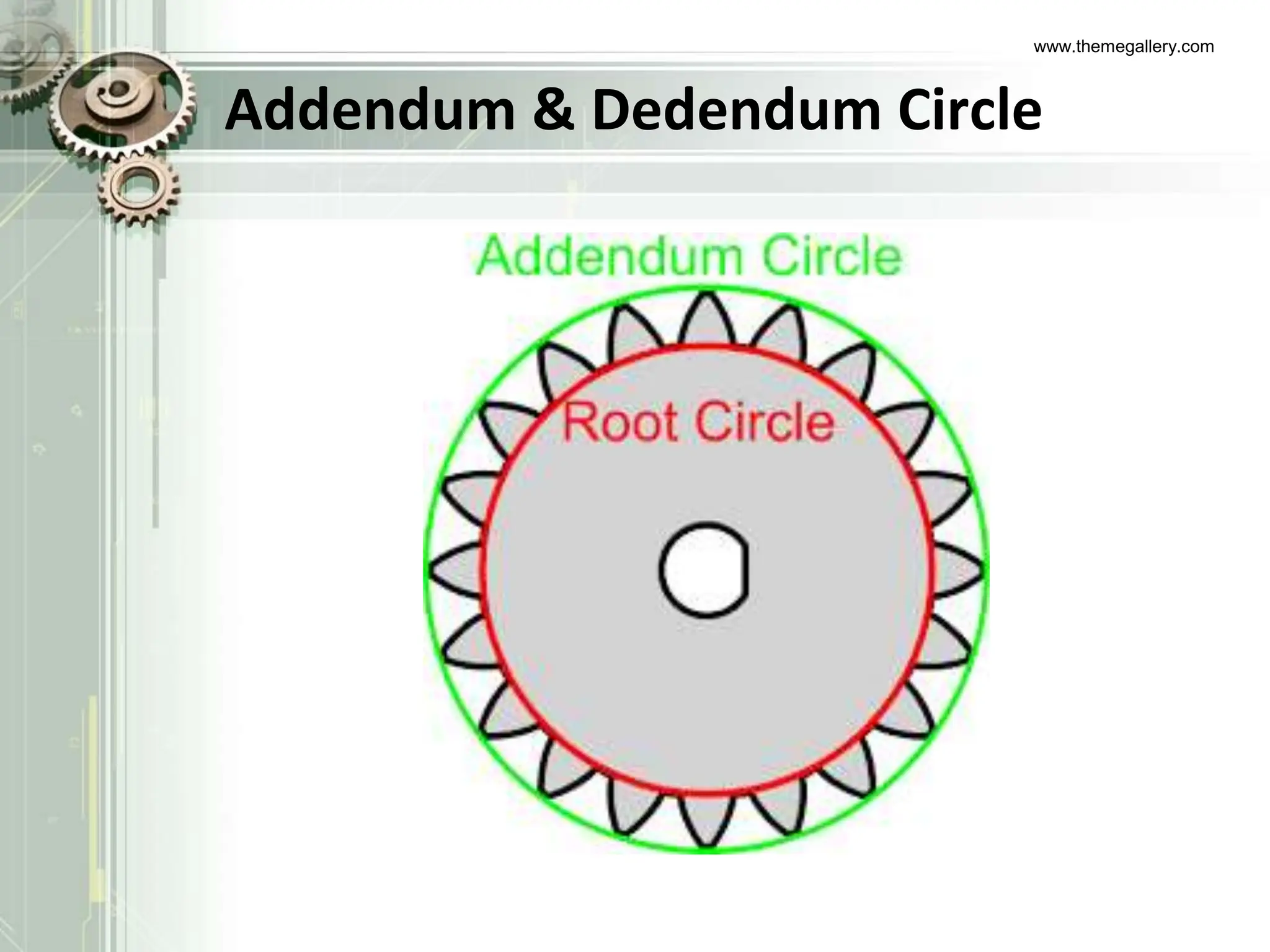

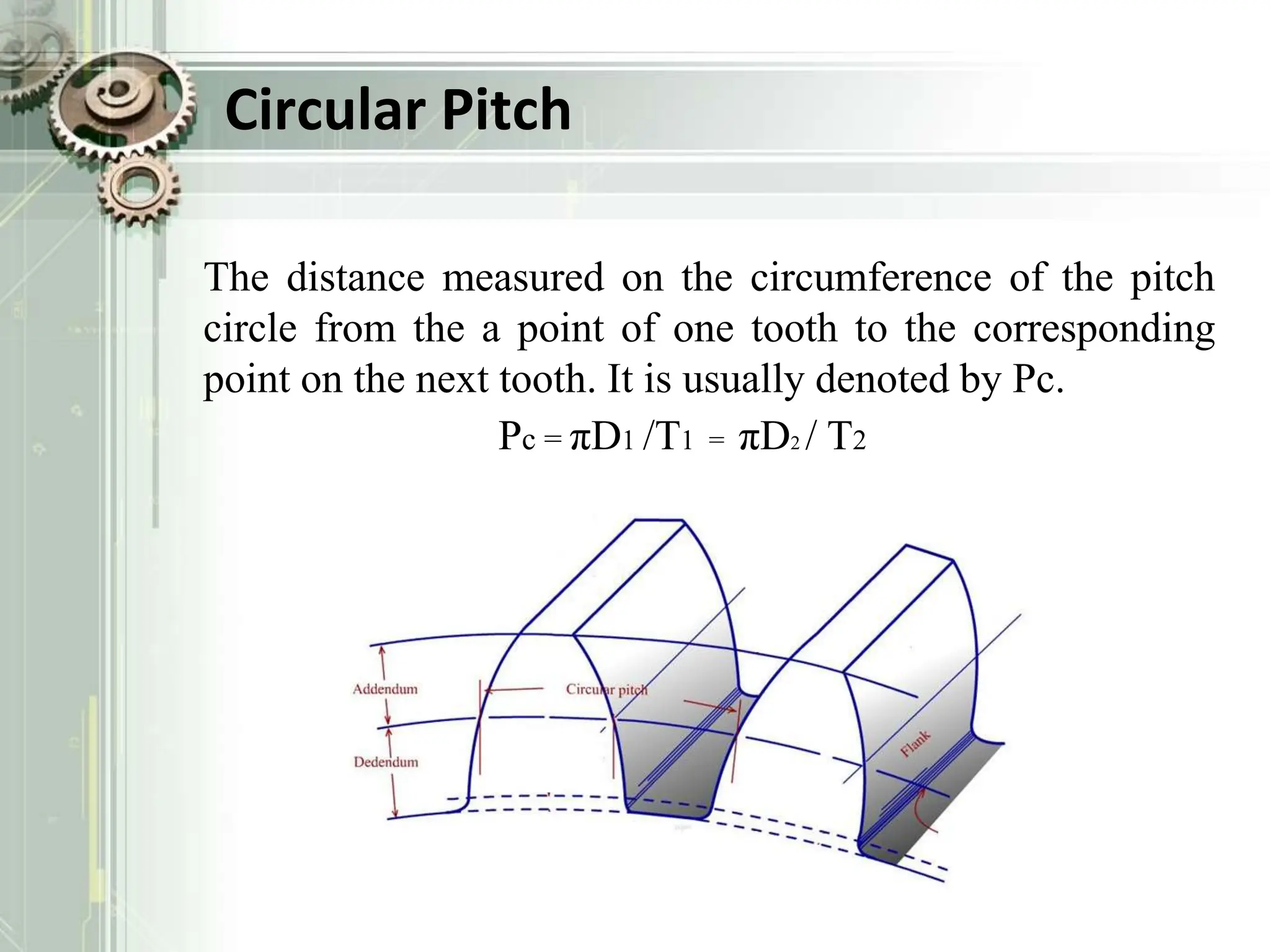

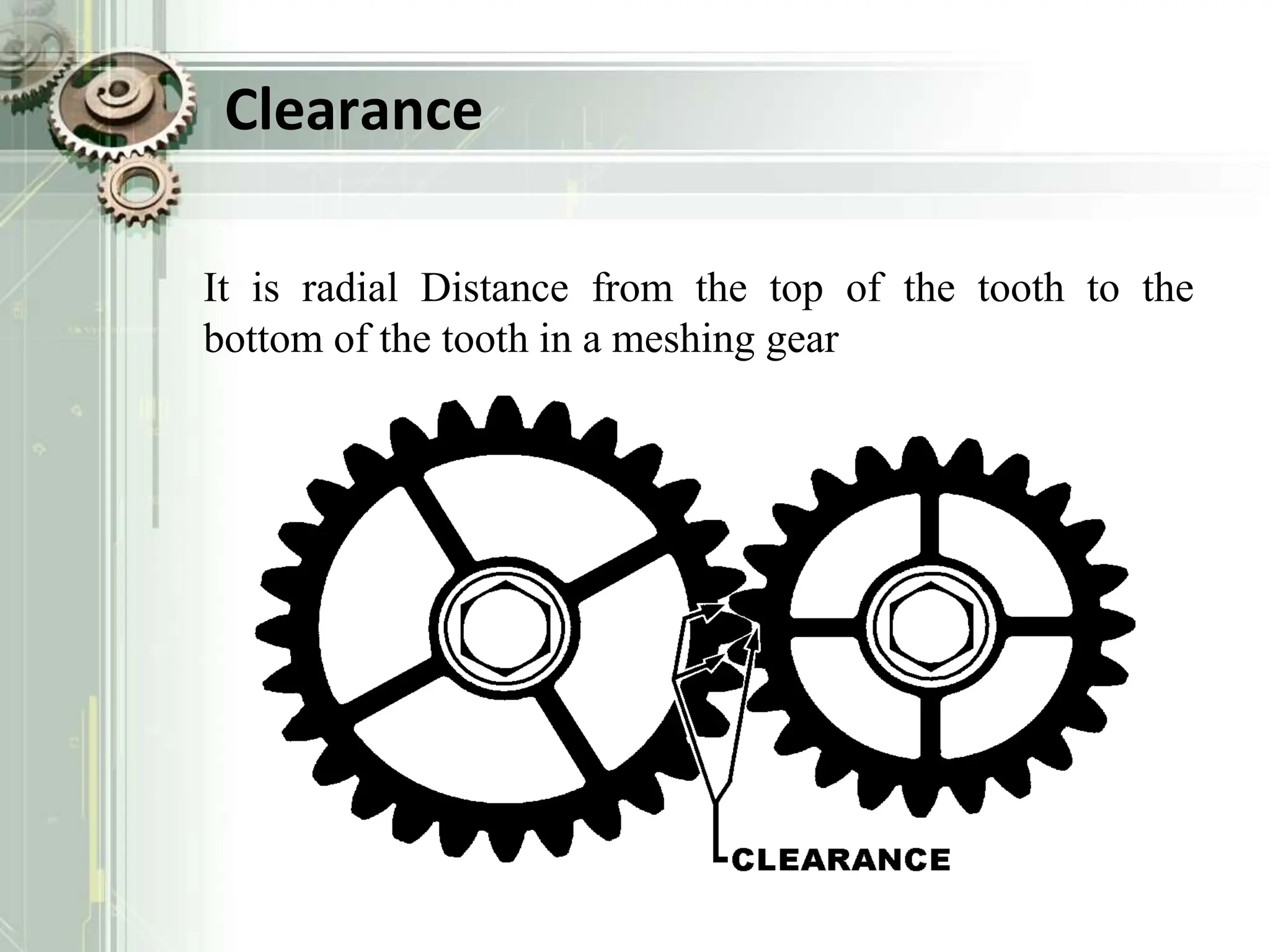

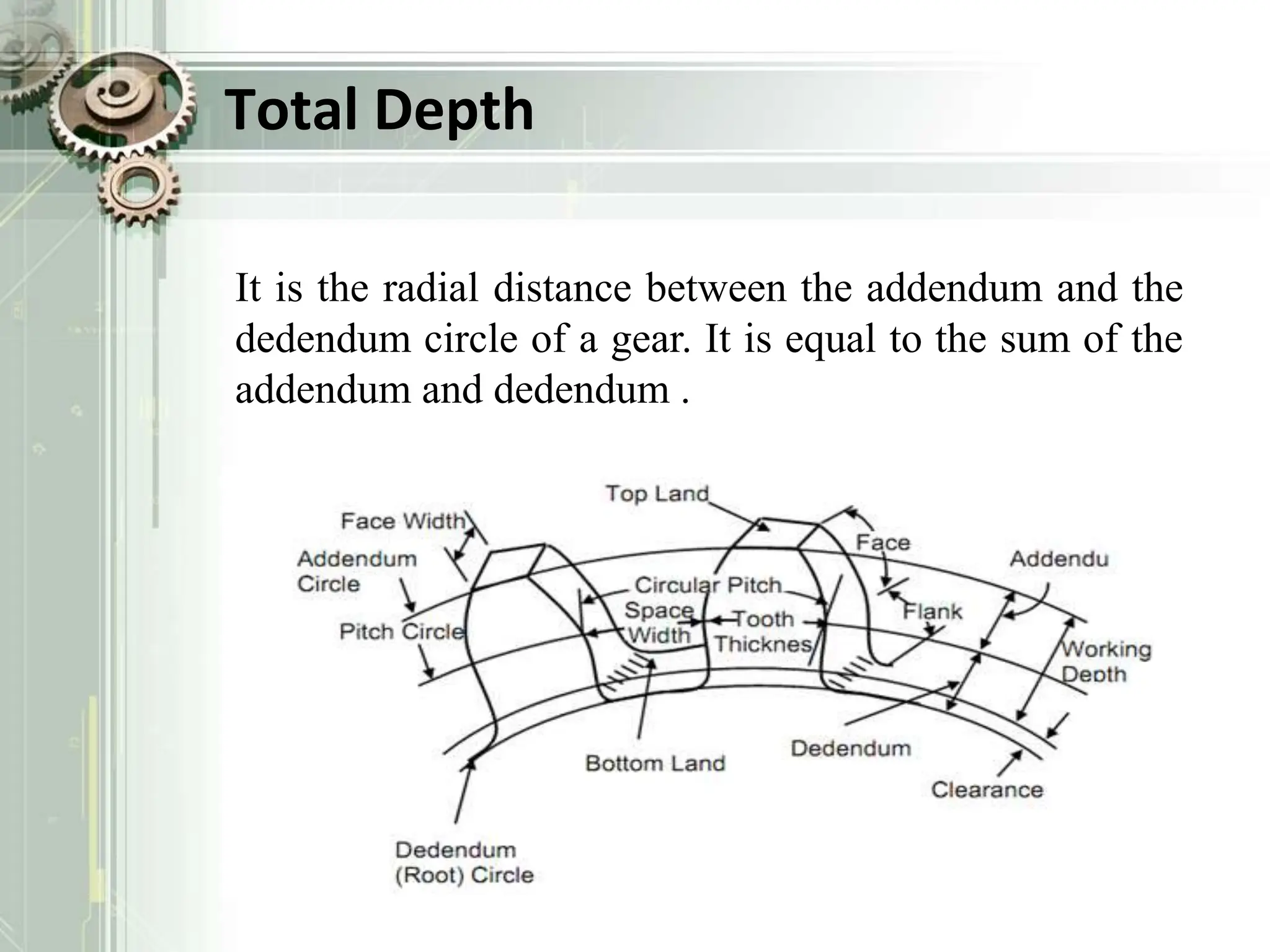

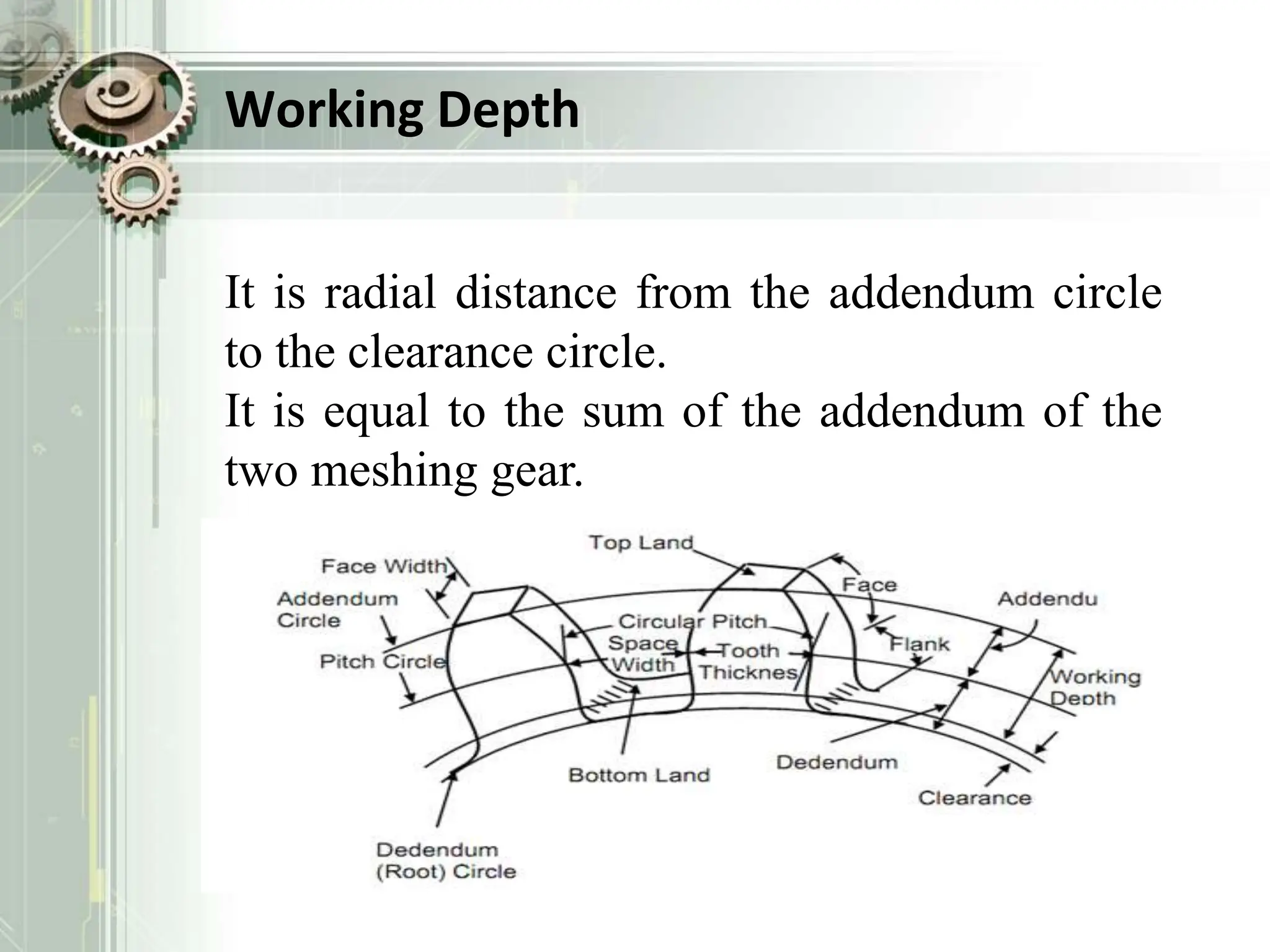

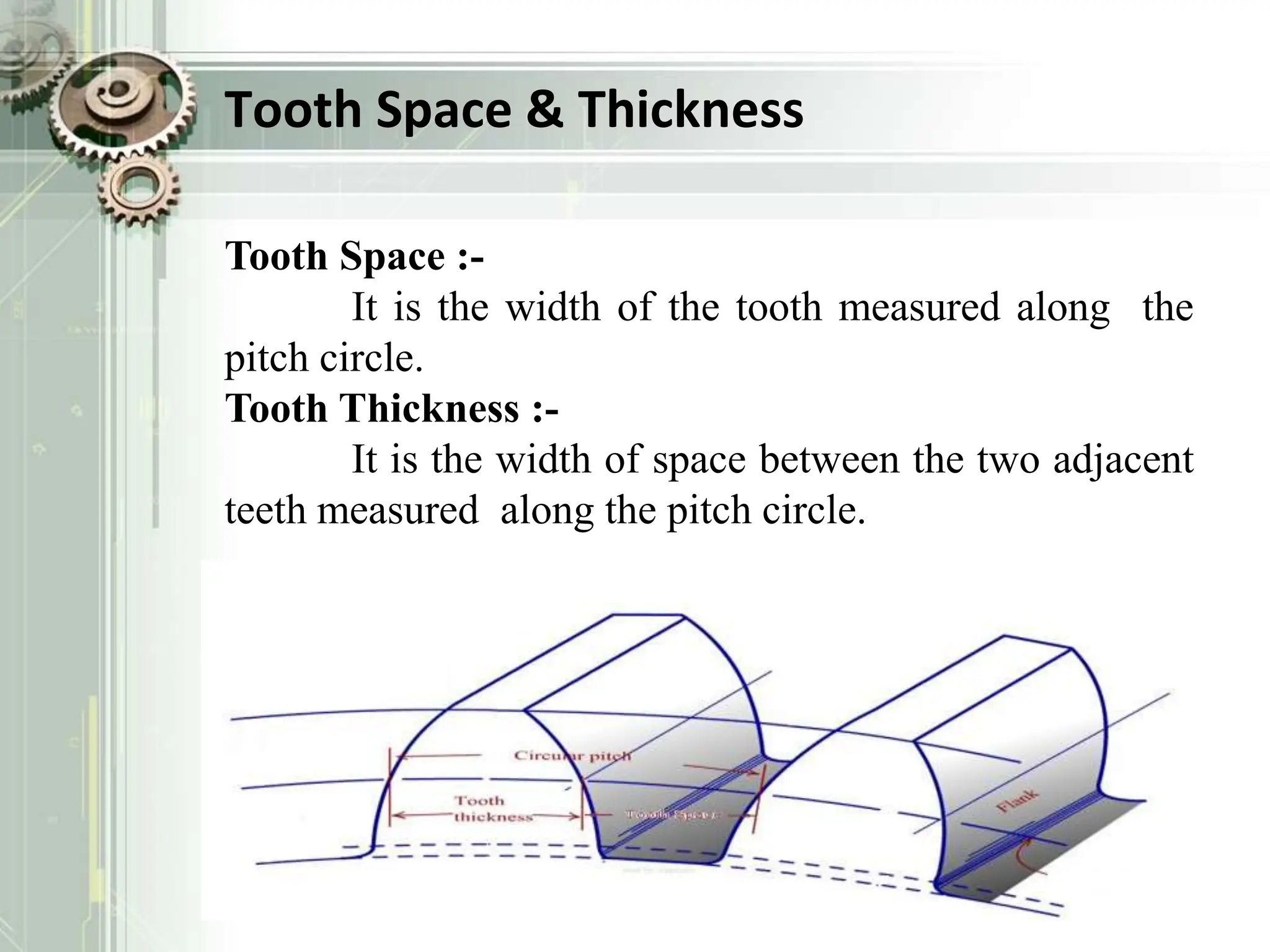

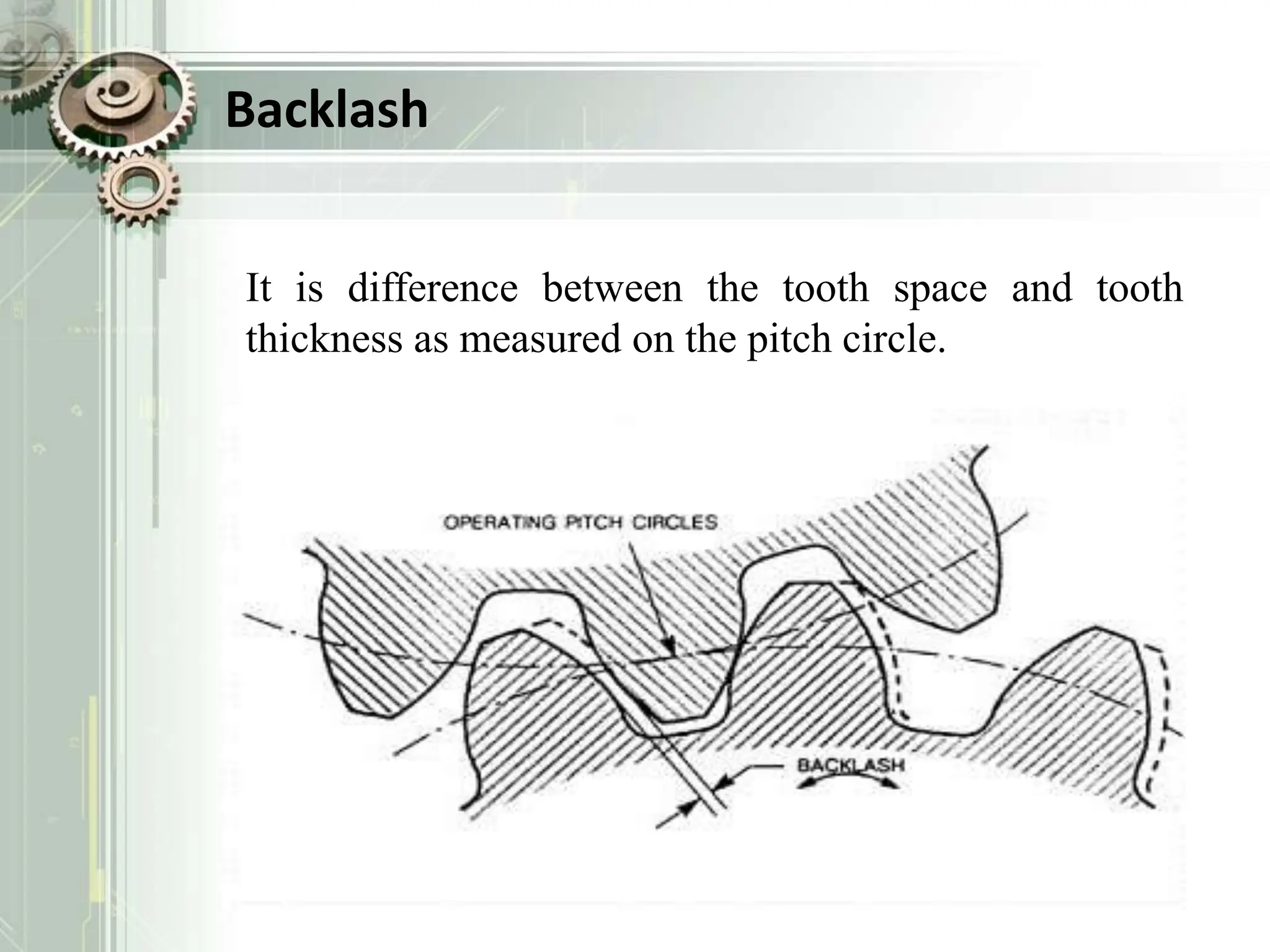

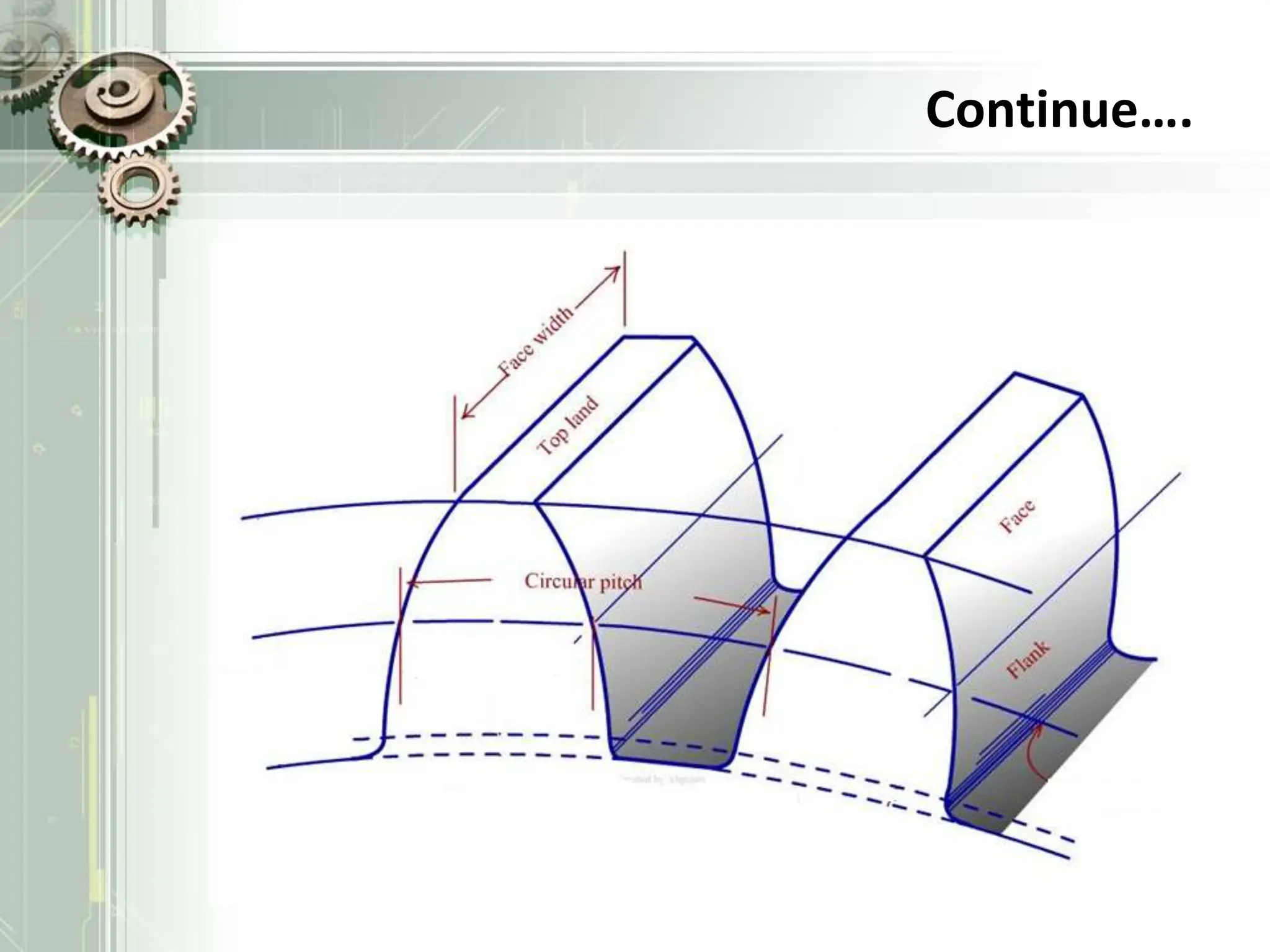

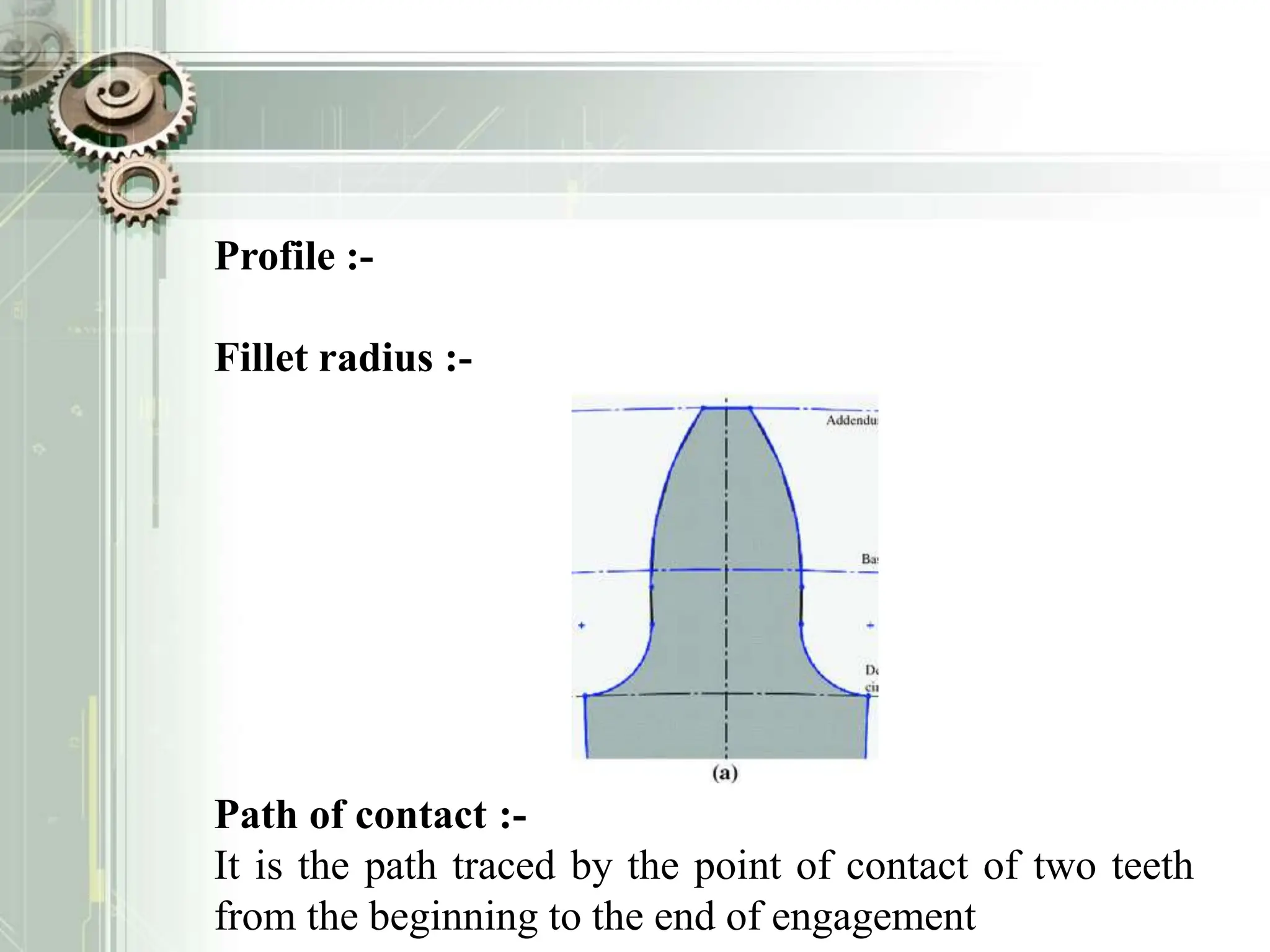

The document provides an overview of gears, including their history, classification, and key terminology used in gear mechanics. It details different types of gears, their functions, and important concepts such as pitch circles, addendum, dedendum, and backlash. The information aims to give a foundational understanding of how gears work and their applications in mechanical engineering.