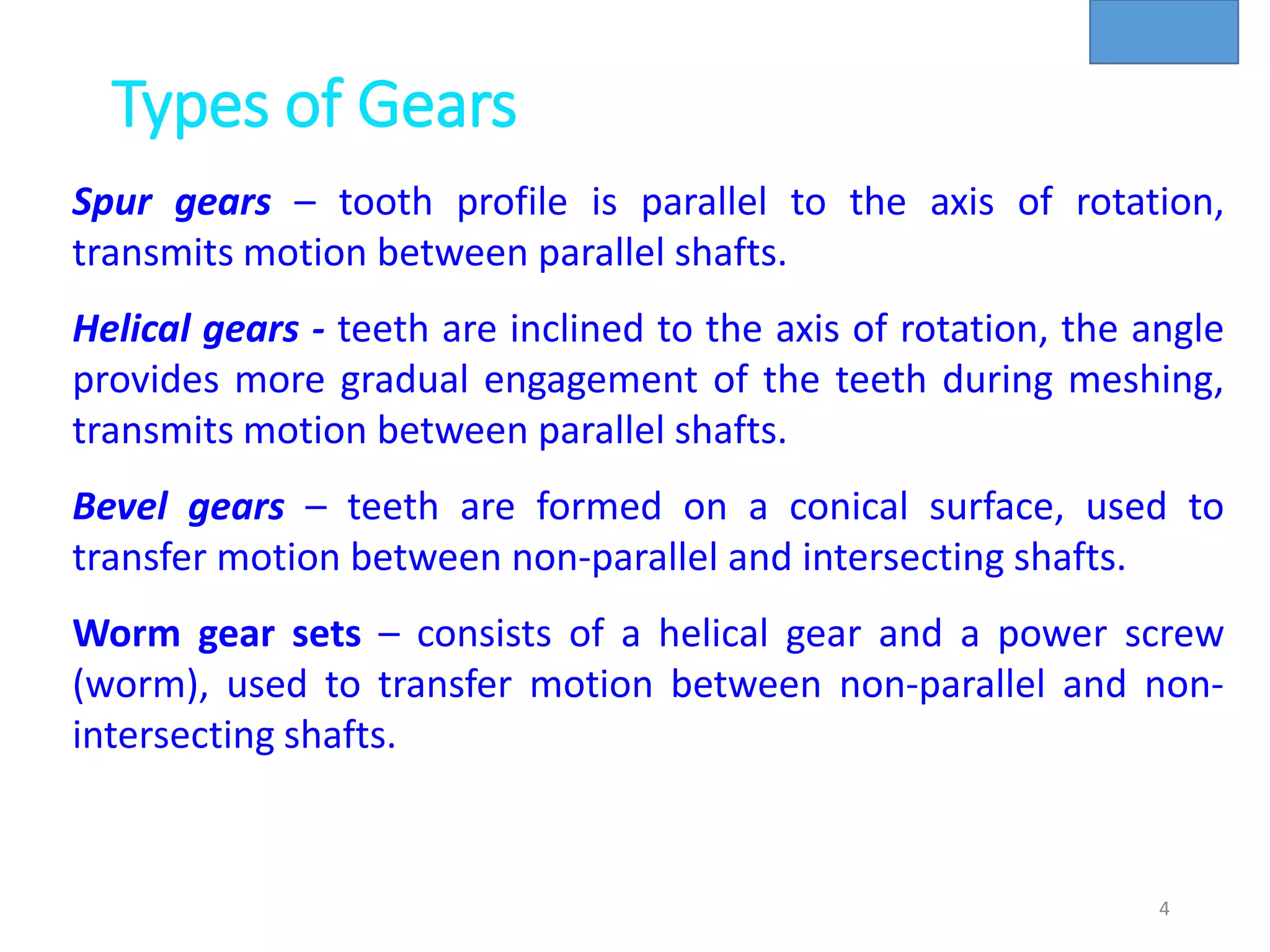

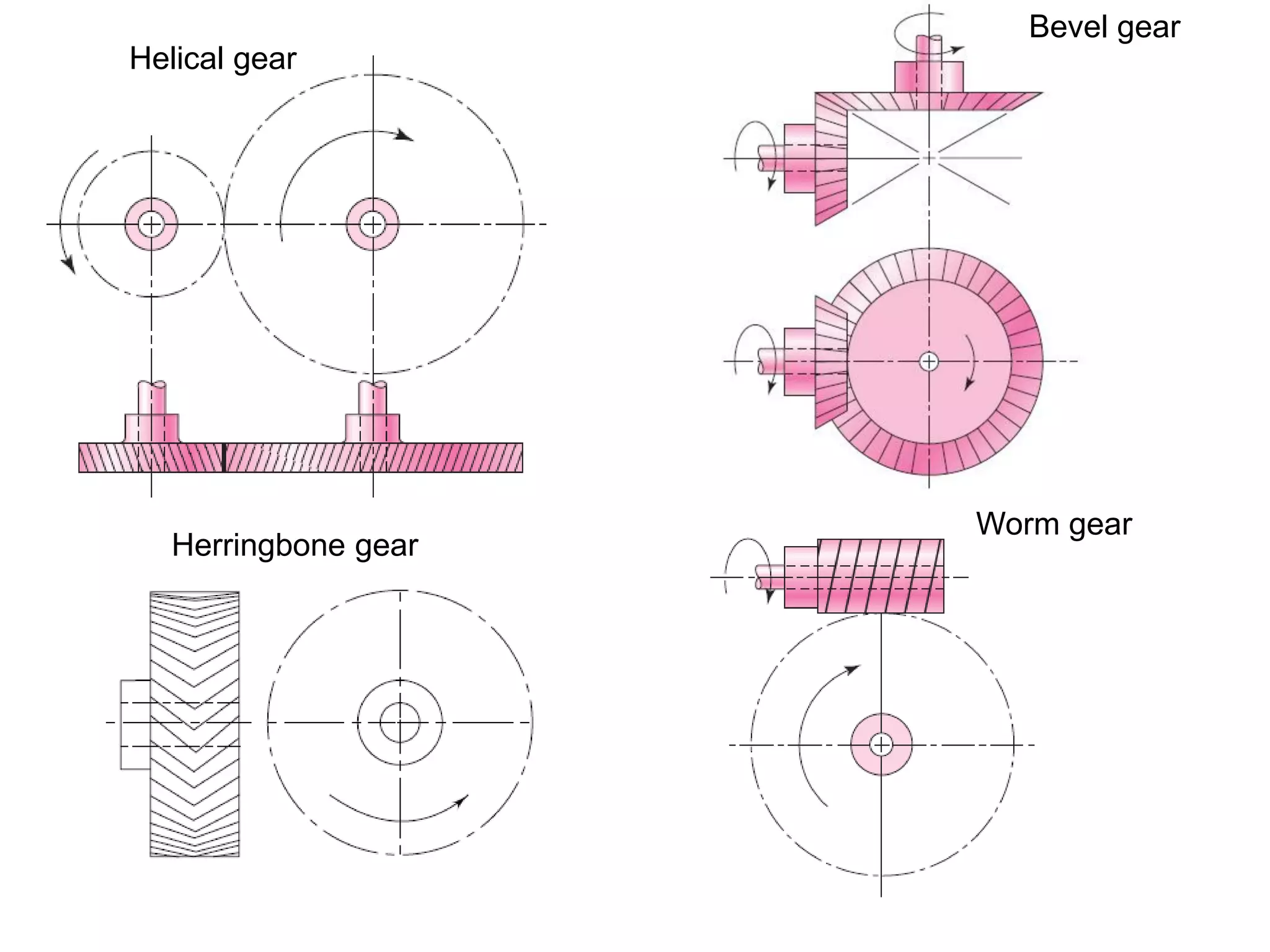

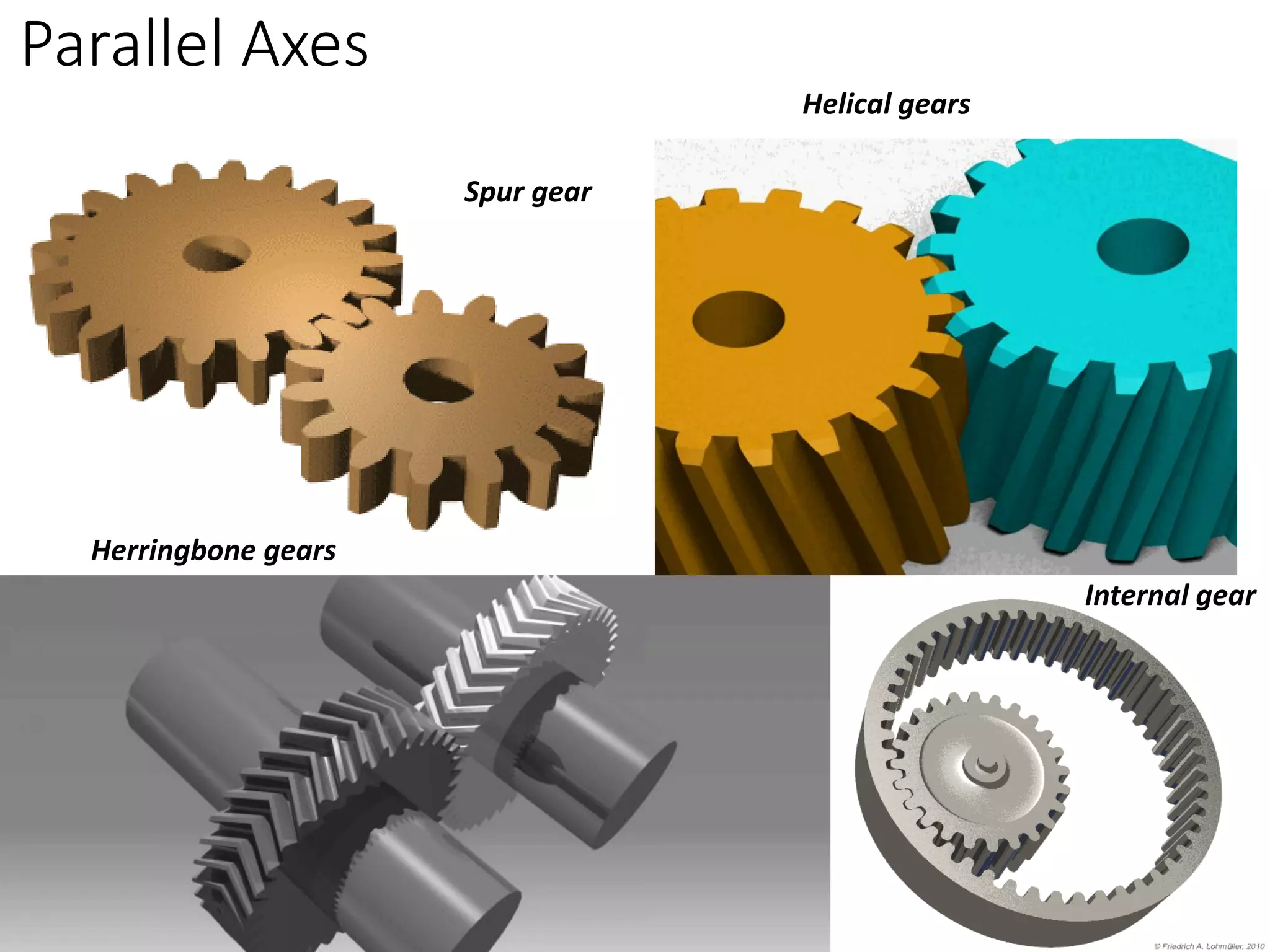

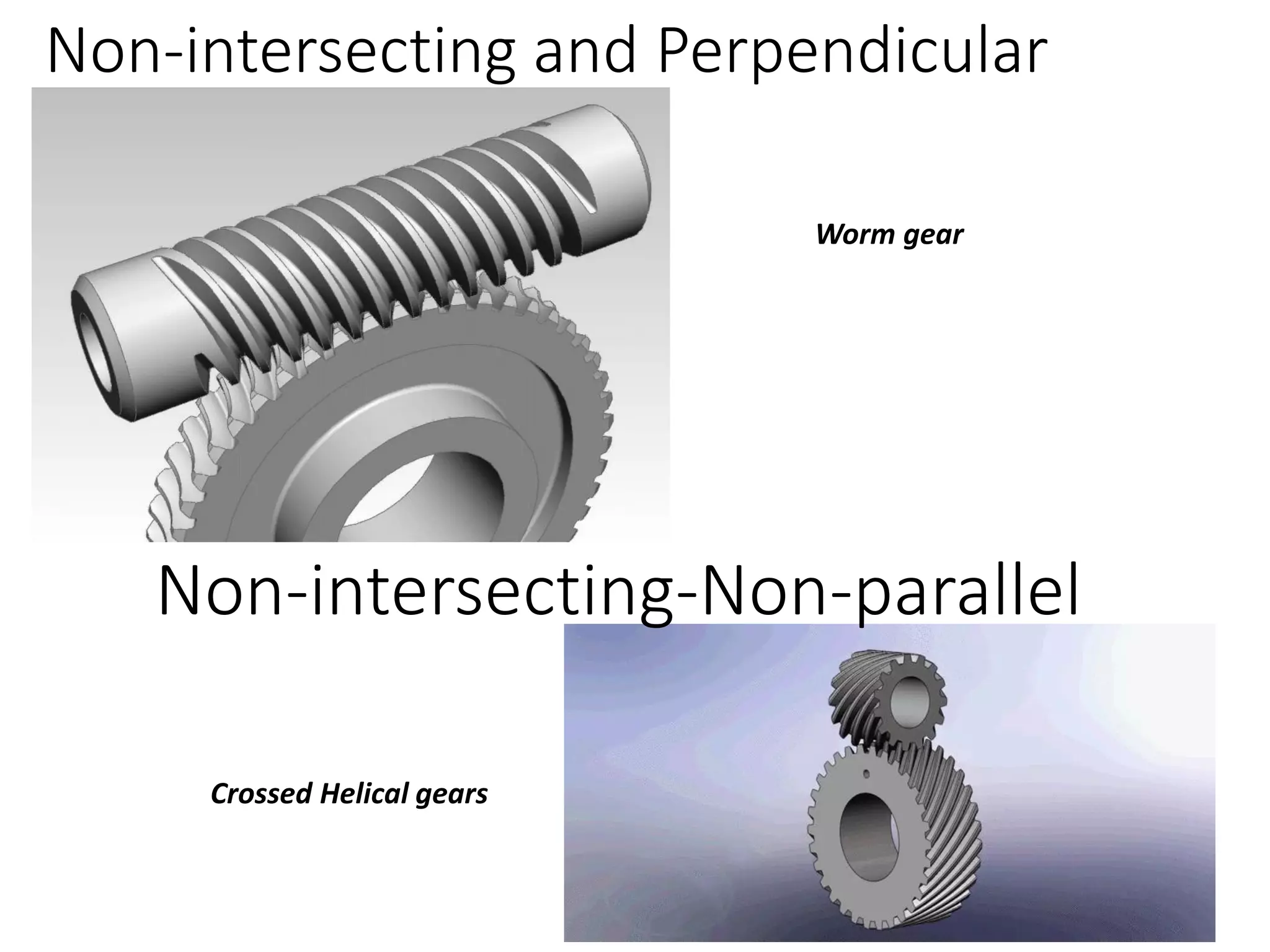

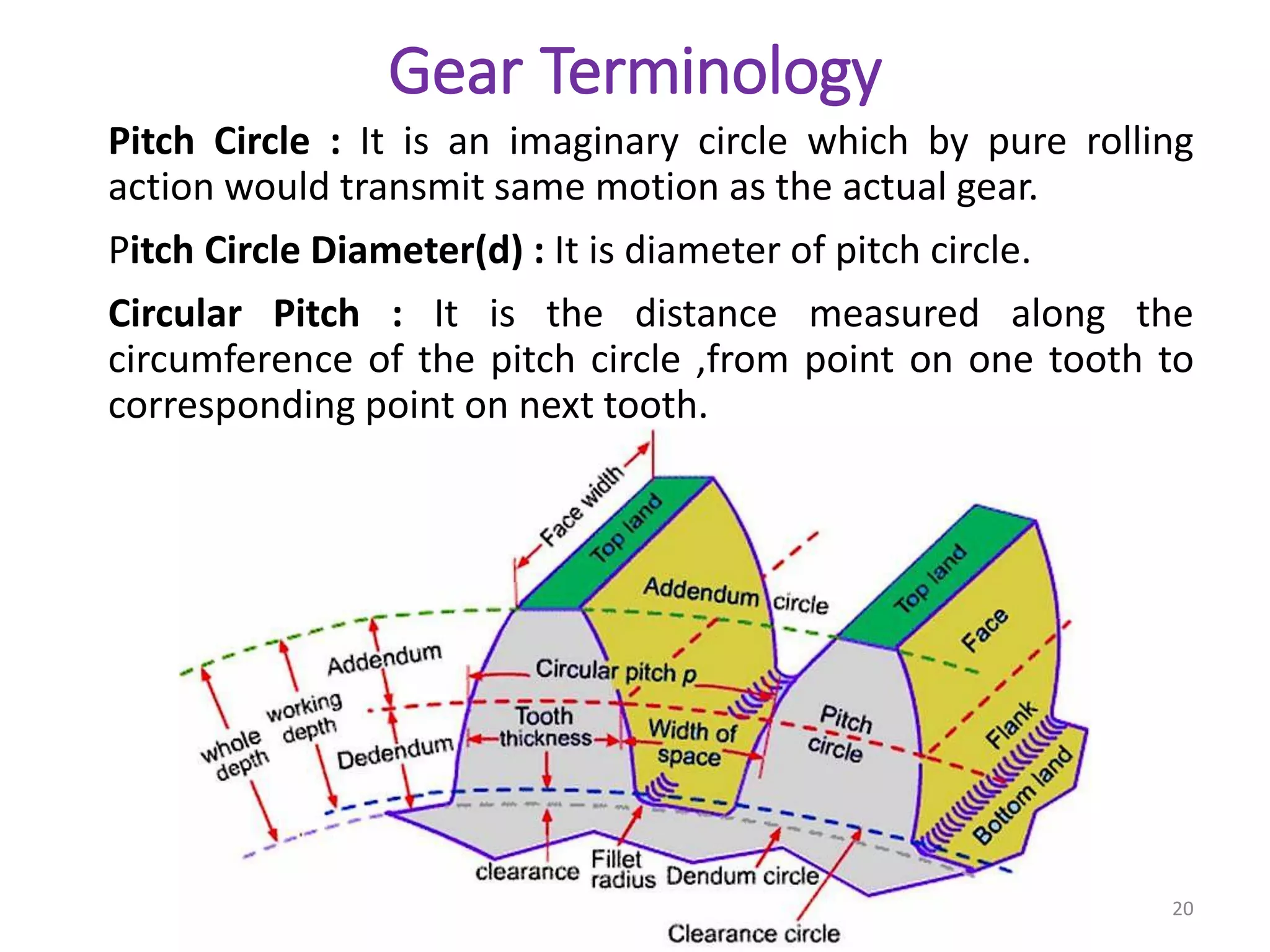

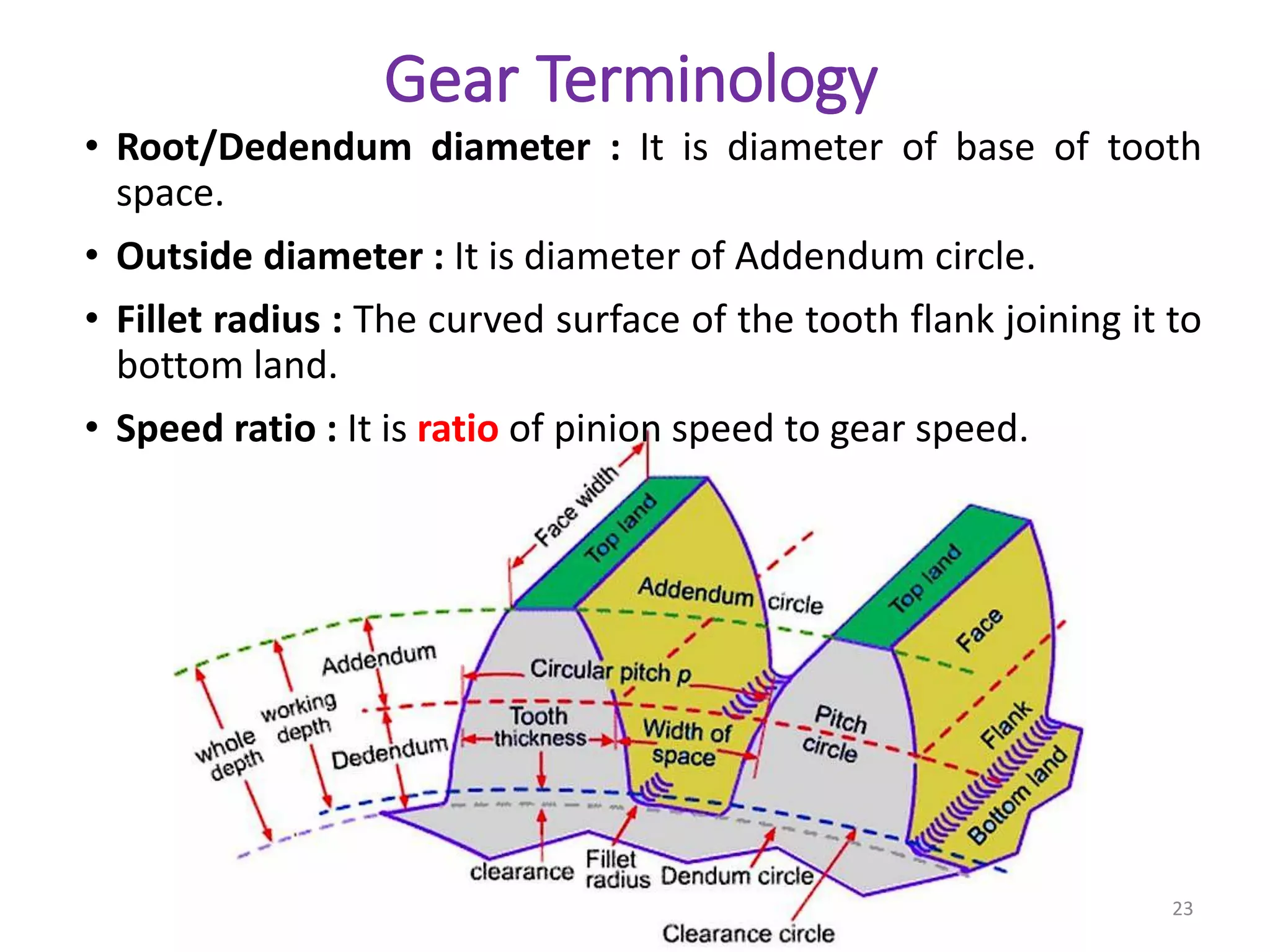

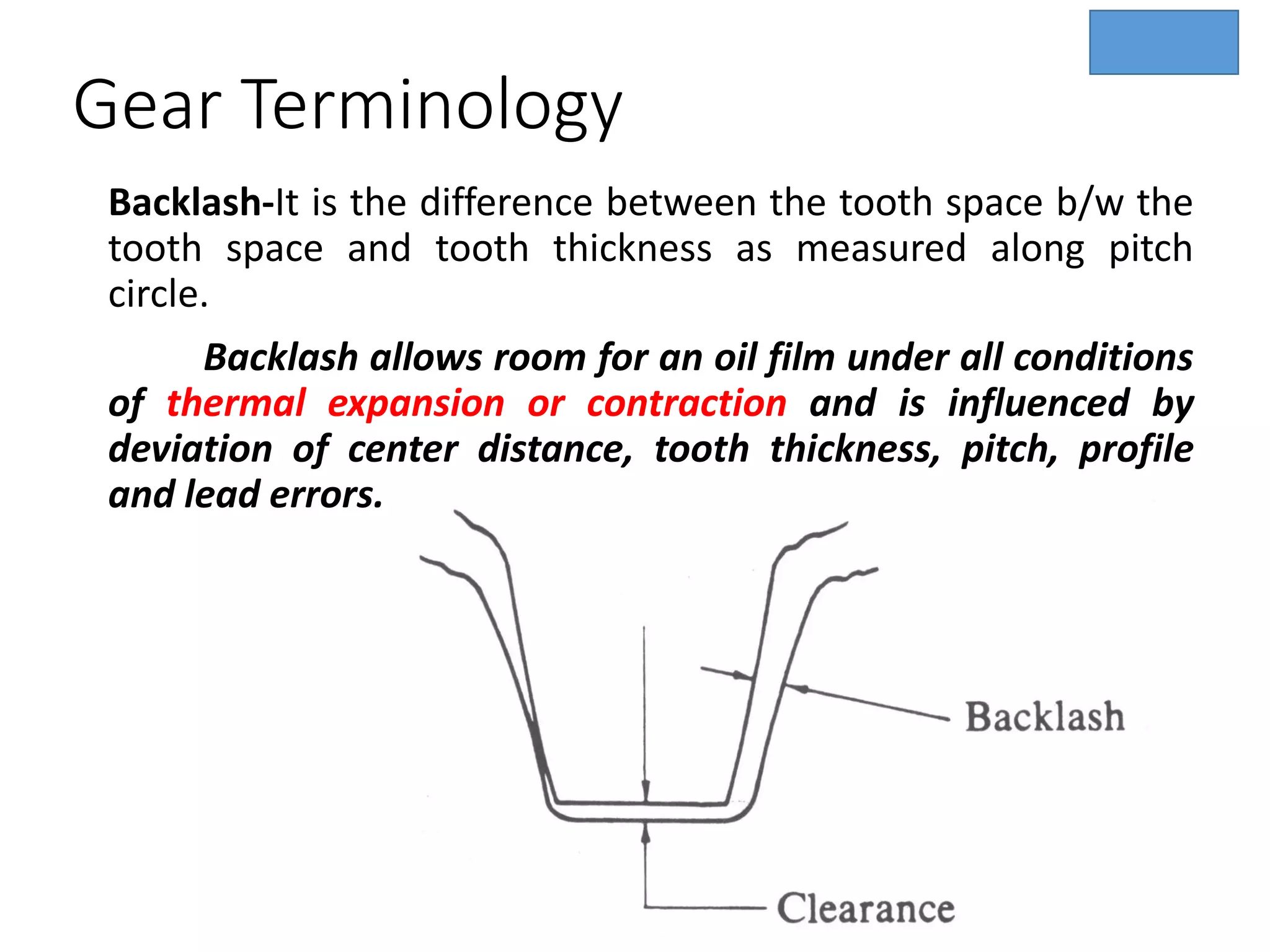

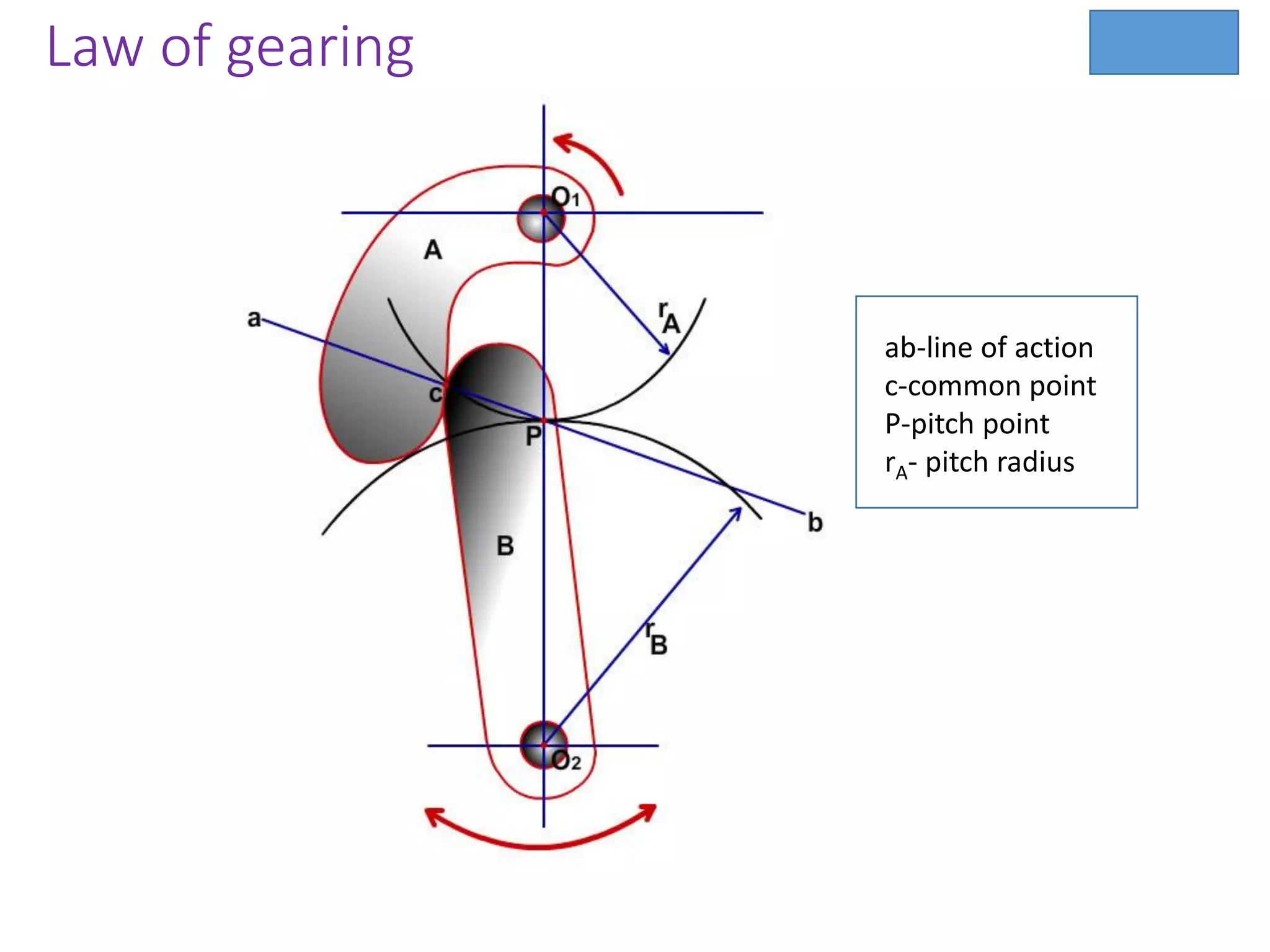

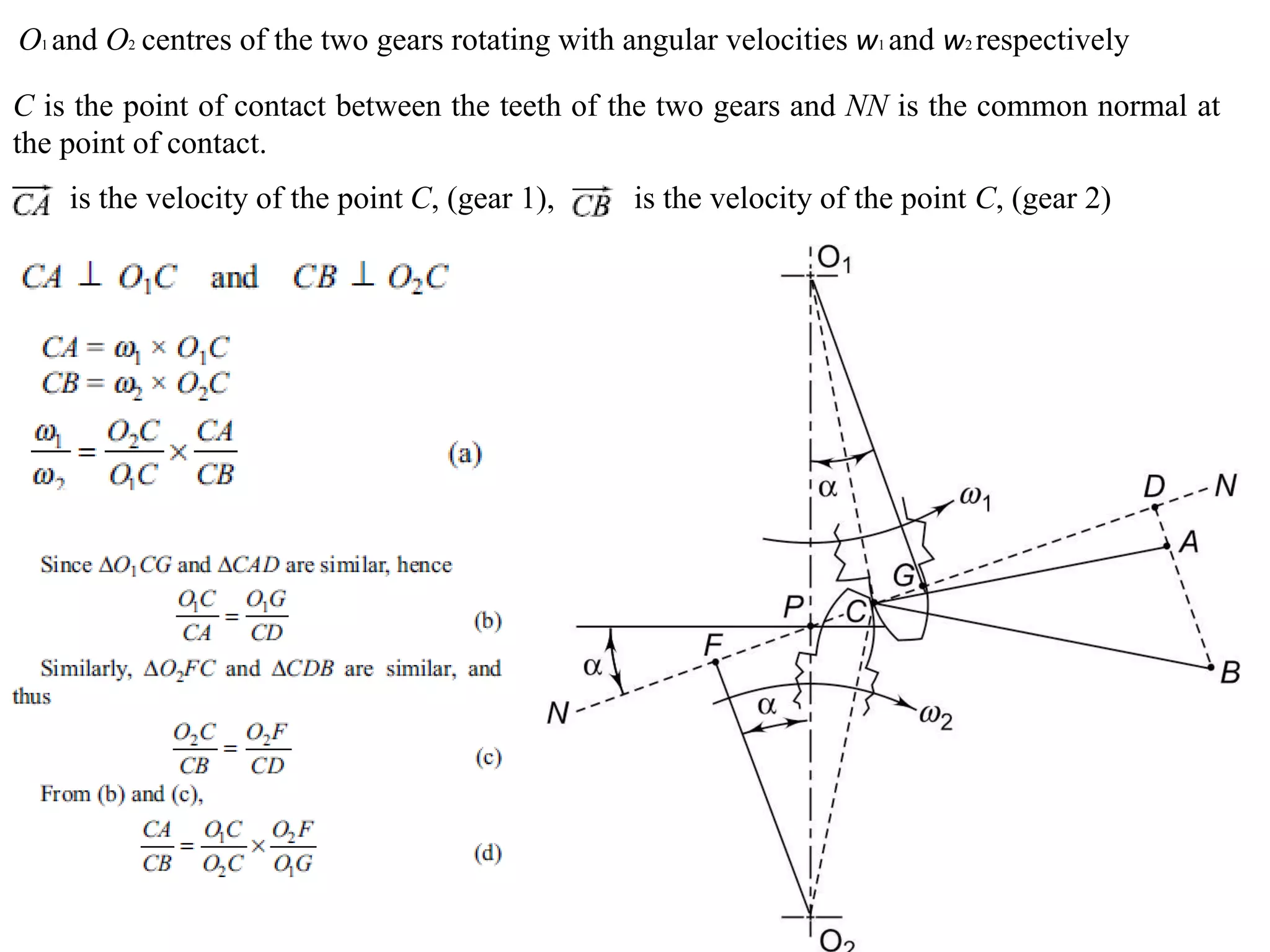

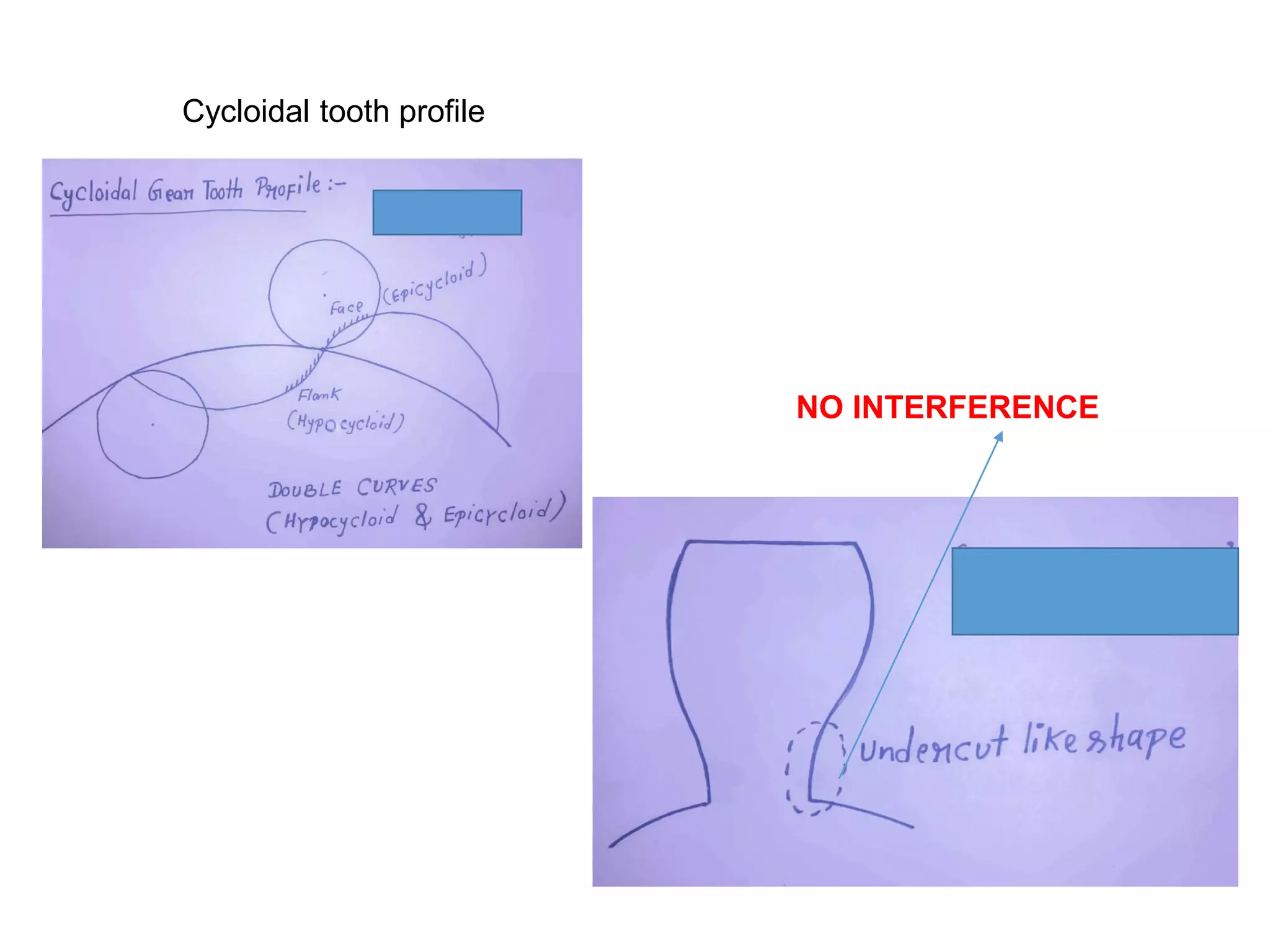

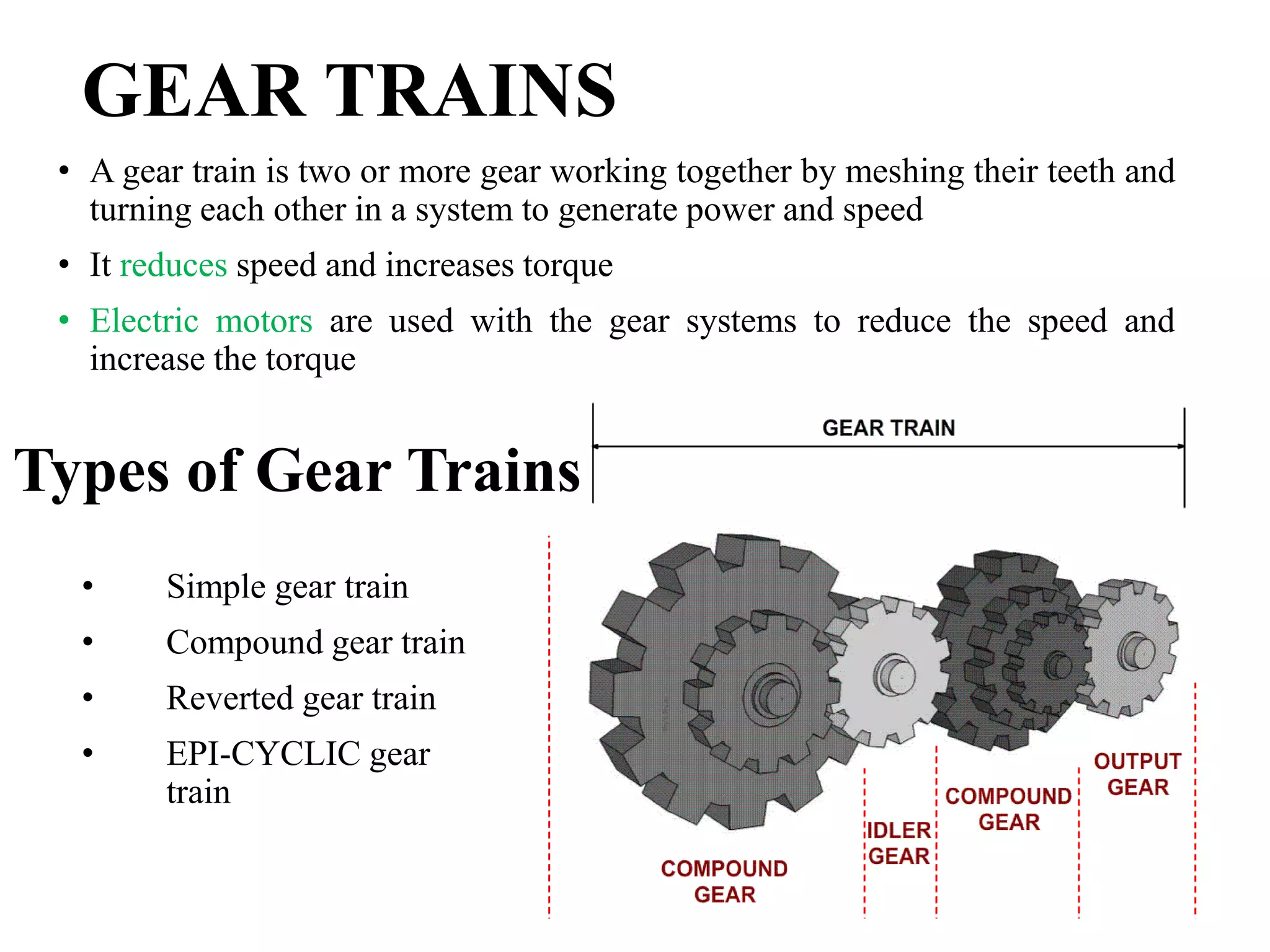

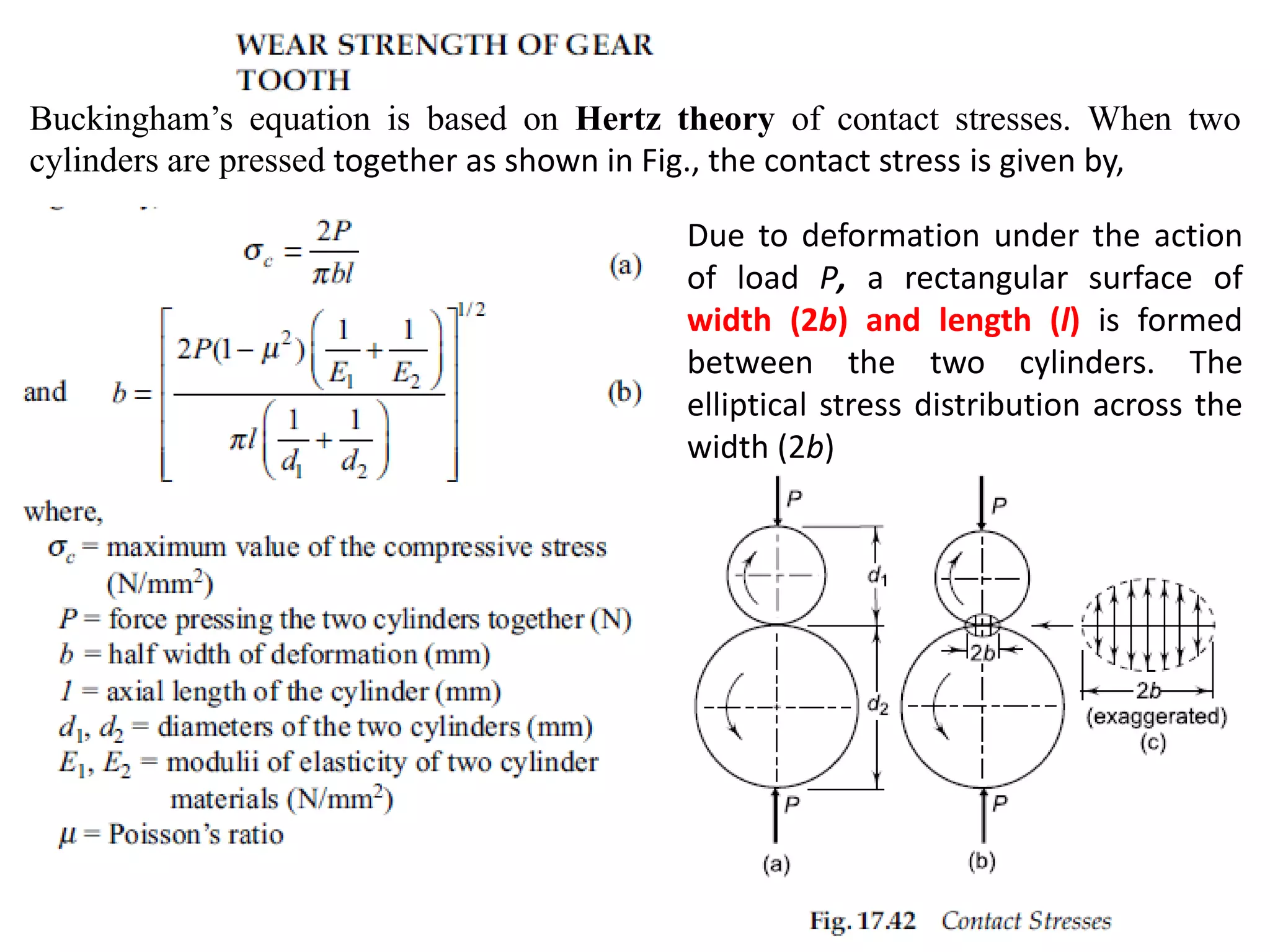

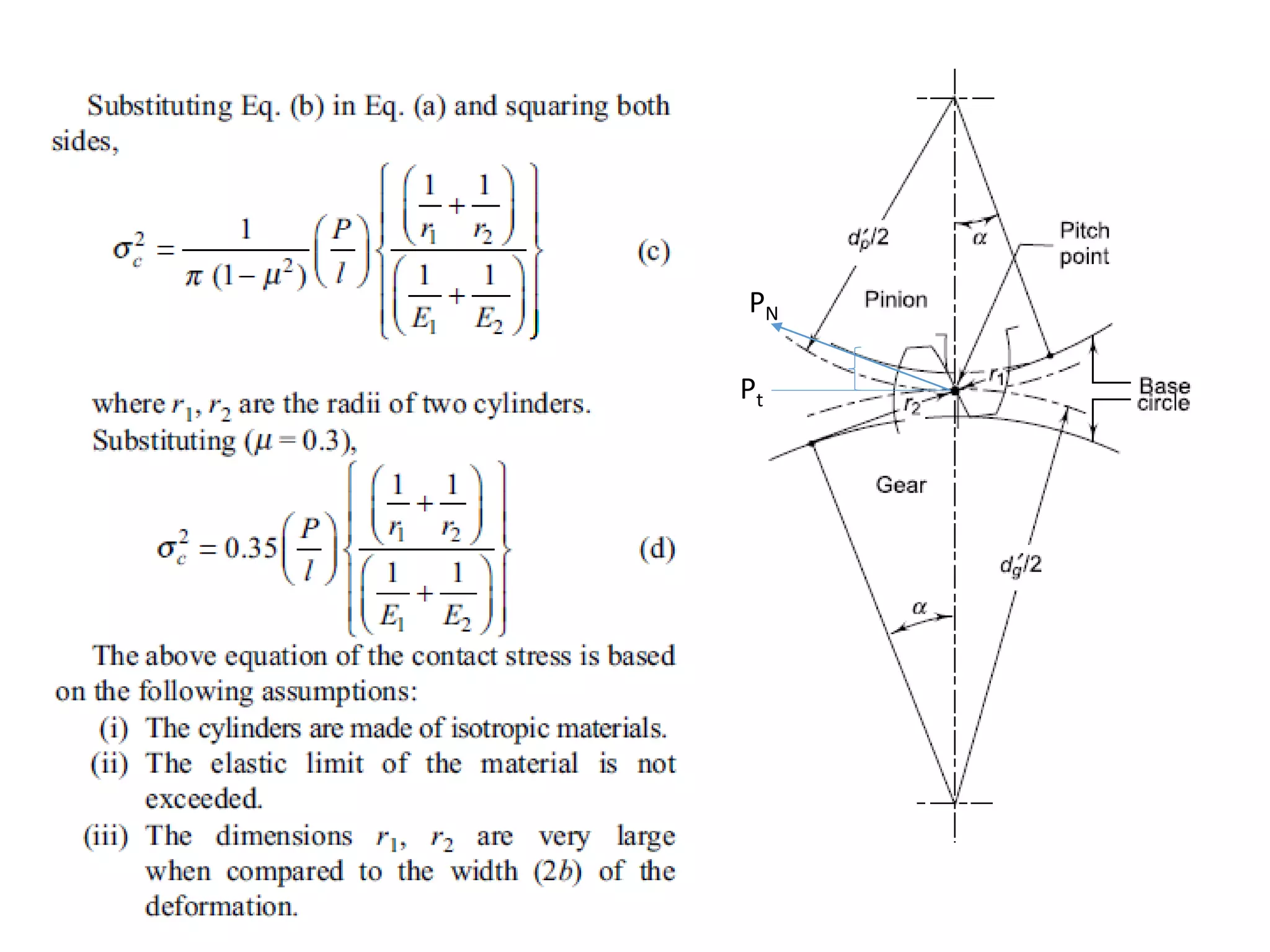

Power transmission involves moving energy from where it is generated to where it is applied. Power is defined as units of energy per unit time. Gears are used to transmit power between rotating or linear shafts by means of teeth that progressively engage. There are different types of gears that transmit motion between parallel shafts, intersecting shafts, and non-parallel shafts. Gear drives are commonly used for power transmission due to their ability to transmit high power and torque over a wide range of speed ratios in a compact package.