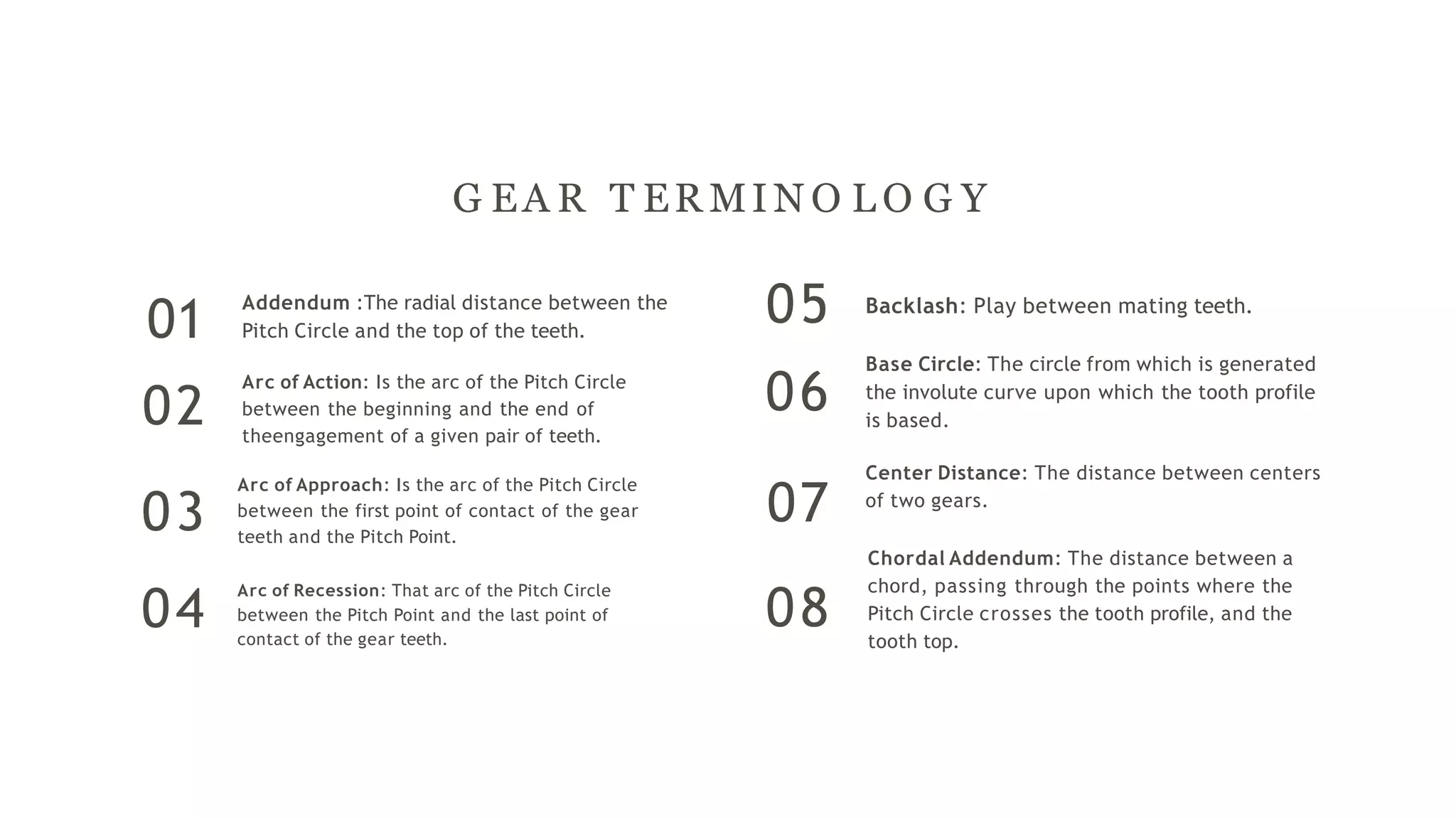

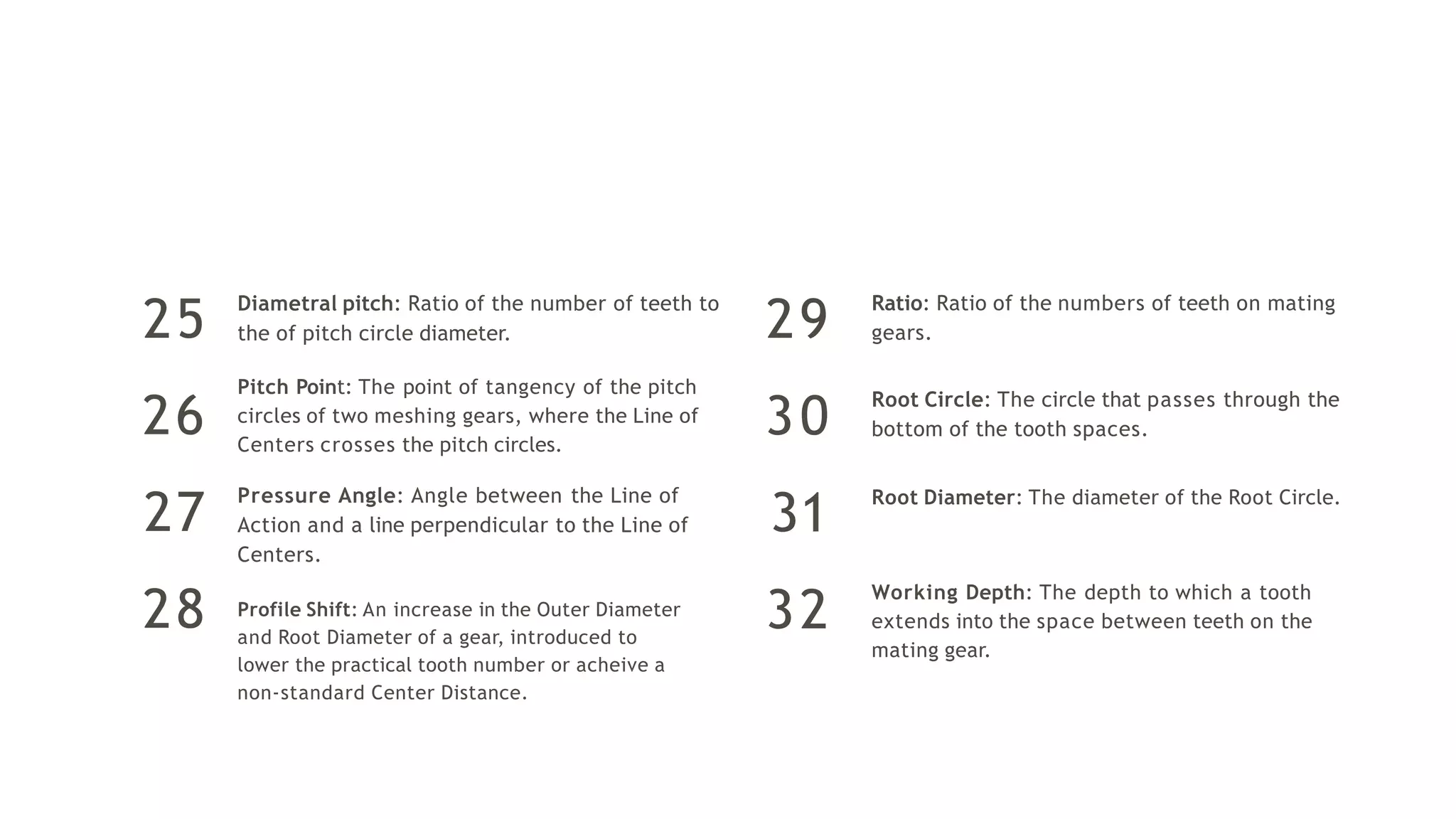

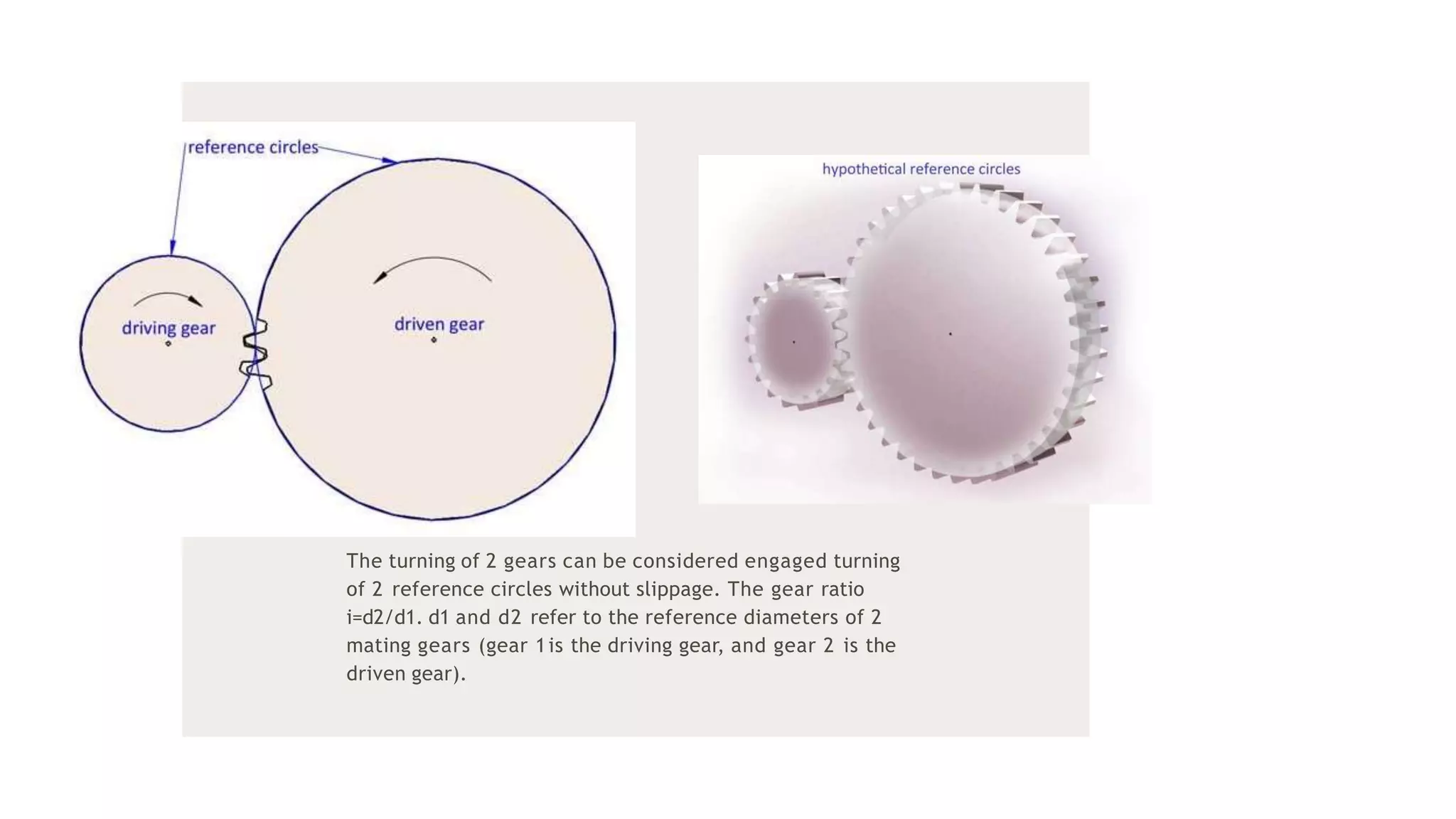

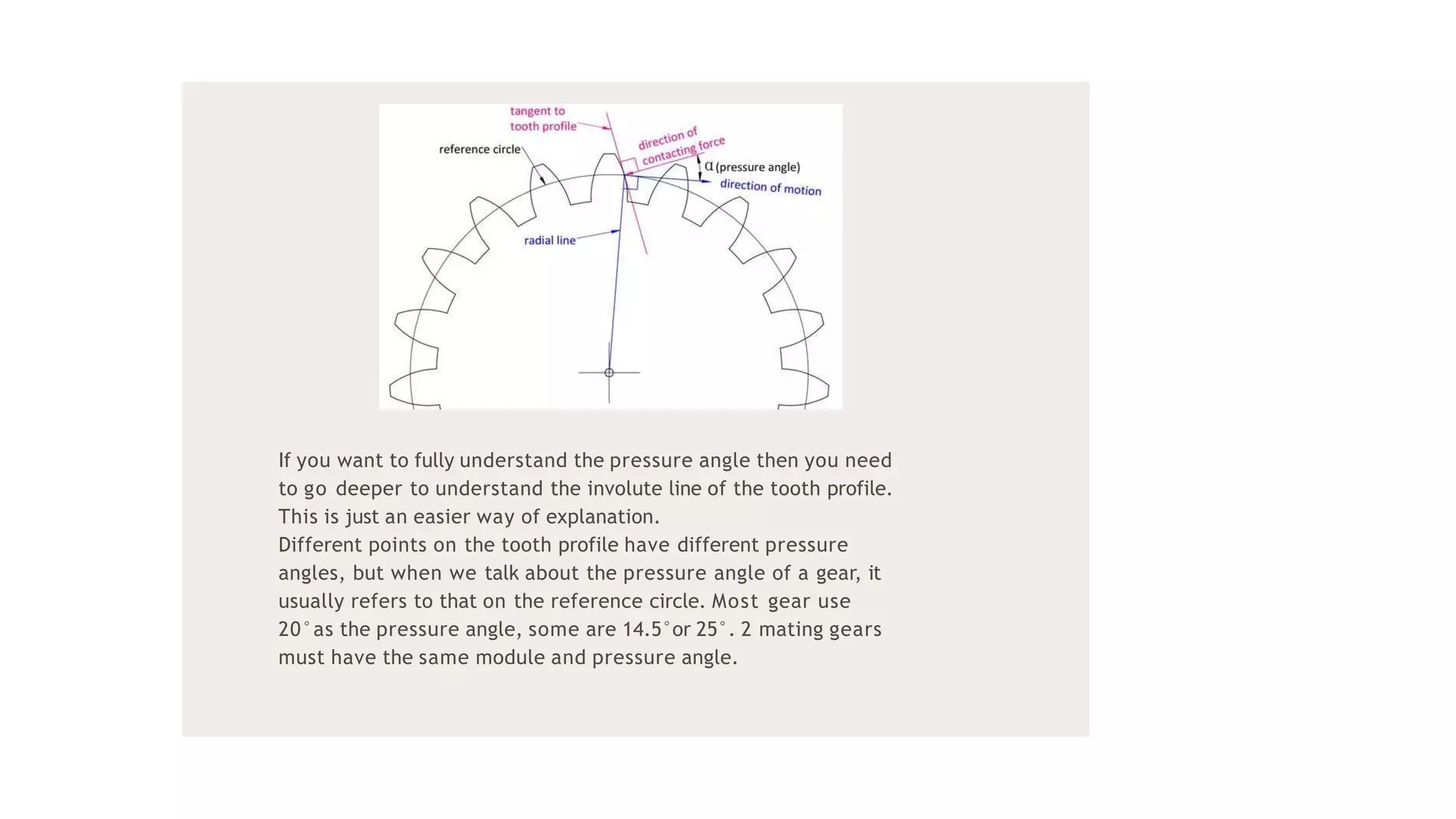

This document provides definitions for common gear terminology used in gear design and calculation. It defines key terms like module, which is the ratio of the pitch diameter to the number of teeth and appears in many gear calculation formulas. It also defines other important terms like reference diameter, center distance, and pressure angle. The reference diameter connects to other parameters and is used in gear ratios to calculate the turning of two engaged gears. Finally, it notes that properly matching gears have the same module and pressure angle.