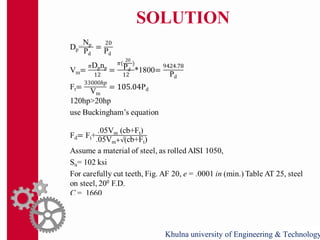

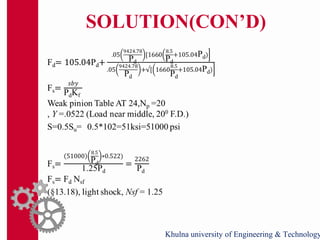

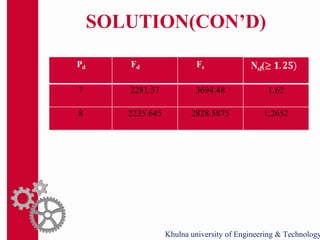

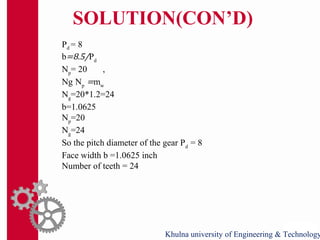

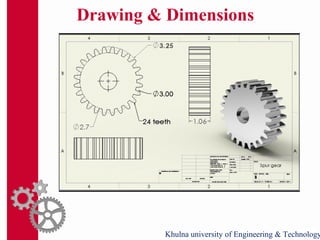

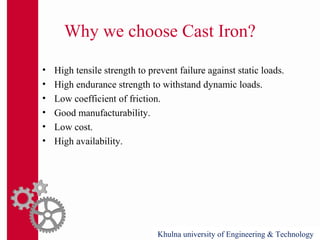

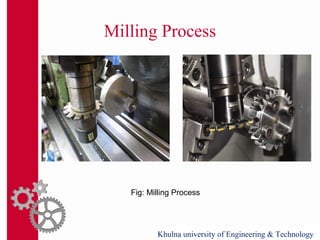

This document discusses the fabrication of a spur gear. It begins with introducing gears and their uses, classifying spur gears and their applications. It then discusses gear terminology and provides examples. The document presents a problem of designing a spur gear to transmit 30hp at 1800rpm. It provides the solution, specifying cast iron material, an 8 pitch diameter, a 1.0625 inch face width, 20 teeth for the pinion and 24 teeth for the gear. Milling is selected as the manufacturing process due to its flexibility, accuracy and cost. Finally, a rendered image of the manufactured spur gear is presented.

![Fabrication Of Spur

Gear

Supervised by

Md.Golam Kader

Professor,

Md Rasedul Islam

Lecturer,

Department of Mechanical

Engineering, KUET

Course ME 3118

Khulna University Of Engineering & Technology

Department of Mechanical Engineering

Submitted By

Md Rezowan Kabir [1205016]

Md Hasanuzzaman [1205017]

Md Abul Kashem Hemel [1205018]

Md Ashik Mahmud [1205019]

Saikat Biswas [1205020]](https://image.slidesharecdn.com/pre-150726053325-lva1-app6891/75/Presentation-on-Spur-Gear-1-2048.jpg)

![GEAR TERMINOLOGY(CON’D)

Pressure angle: Pressure angle in relation to gear teeth, also known

as the angle of obliquity, is the angle between the tooth face and the

gear wheel tangent. It is more precisely the angle at a pitch point

between the line of pressure (which is normal to the tooth surface)

and the plane tangent to the pitch surface.

Fig: Pressure angle of spur gear[1]

Khulna university of Engineering & Technology](https://image.slidesharecdn.com/pre-150726053325-lva1-app6891/85/Presentation-on-Spur-Gear-13-320.jpg)

![GEAR TERMINOLOGY

Fig2: Spur gear terminology[2] Fig3: Spur gear terminology[3]](https://image.slidesharecdn.com/pre-150726053325-lva1-app6891/85/Presentation-on-Spur-Gear-14-320.jpg)

![References

[1] FAIRES VIRGIL MORING, “DESIGN OF MACHINE

ELEMENTS”, 4th

edition, The Macmillan Company, New

York/Collier-Macmillan Limited, London

[2] Jain R.K., “ Production Technology”, 16th

edition, 2-B, Nath

Market, Nai Sarak, Delhi-110006

[3]http://www.brighthubengineering.com/manufacturing-

technology/7118-gear-manufacturing-methods

Khulna university of Engineering & TechnologyKhulna university of Engineering & Technology](https://image.slidesharecdn.com/pre-150726053325-lva1-app6891/85/Presentation-on-Spur-Gear-30-320.jpg)