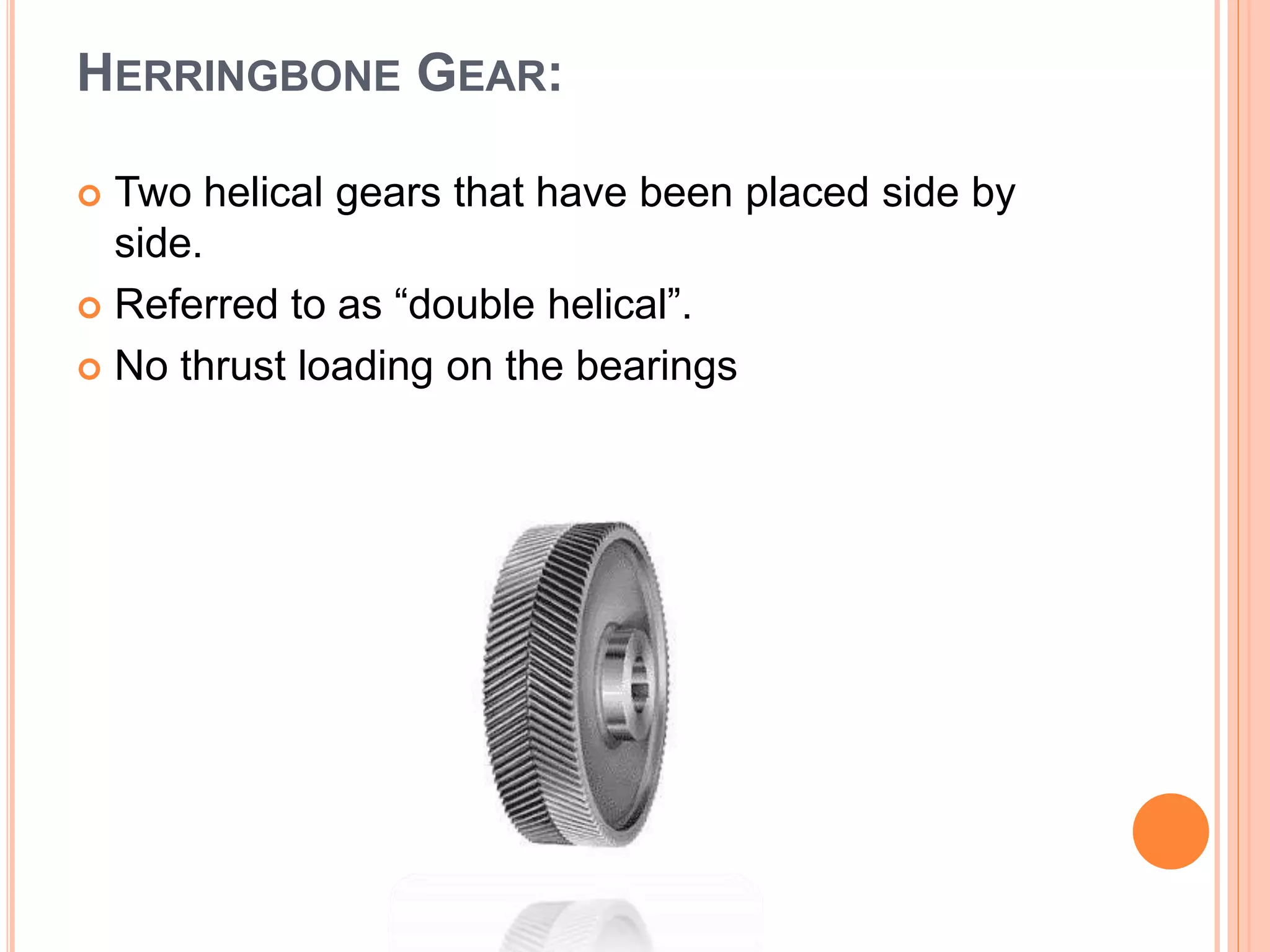

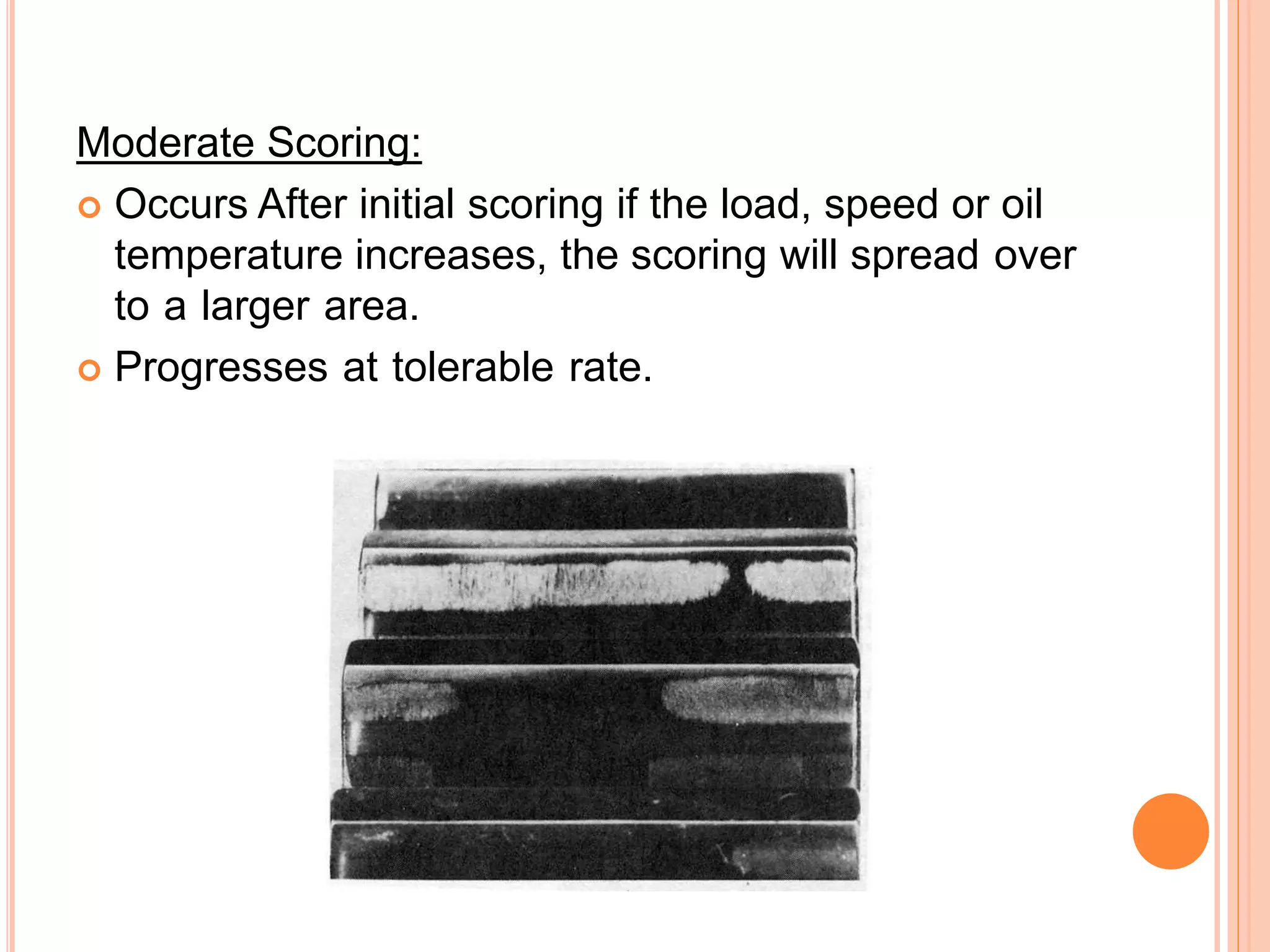

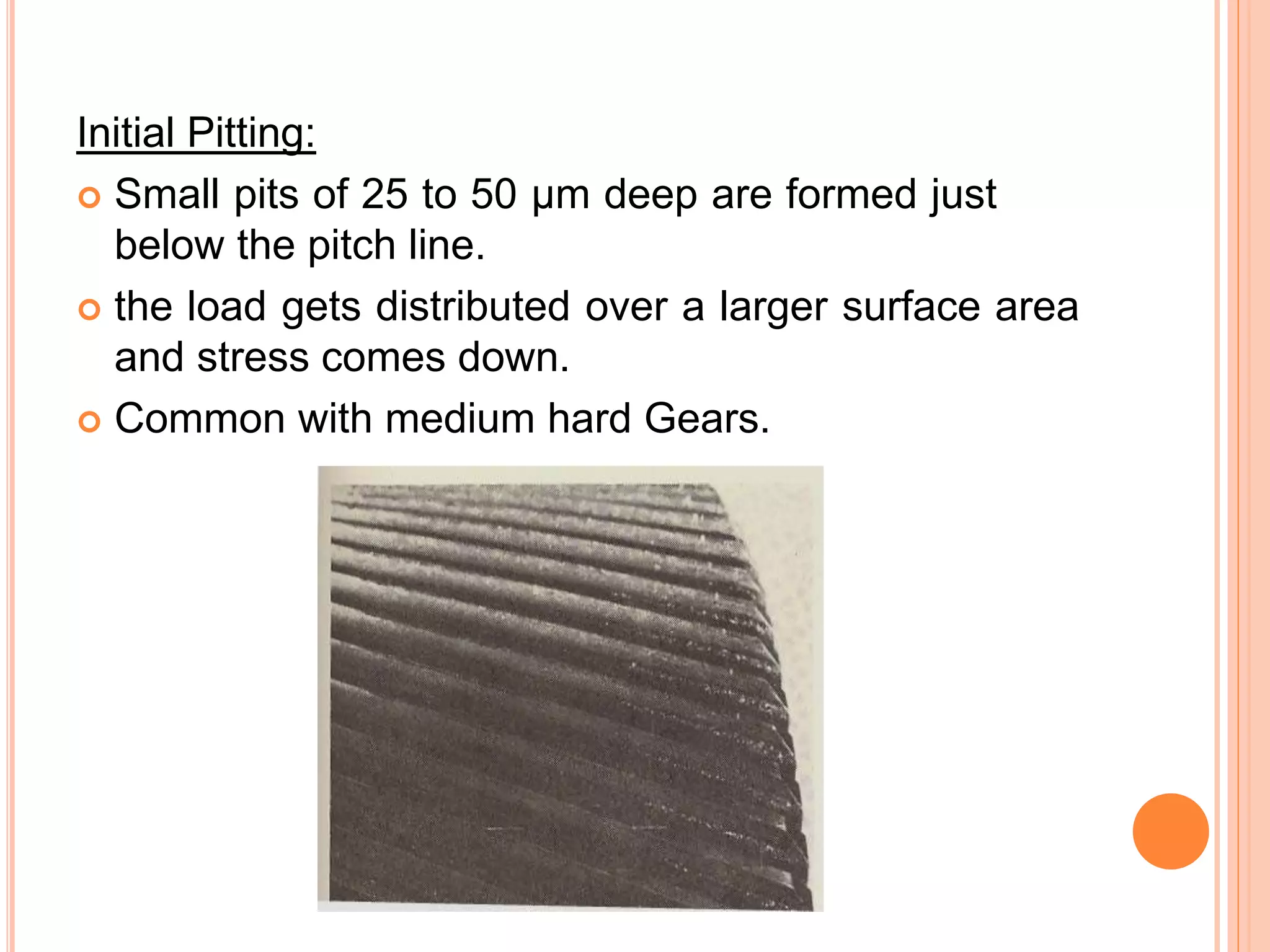

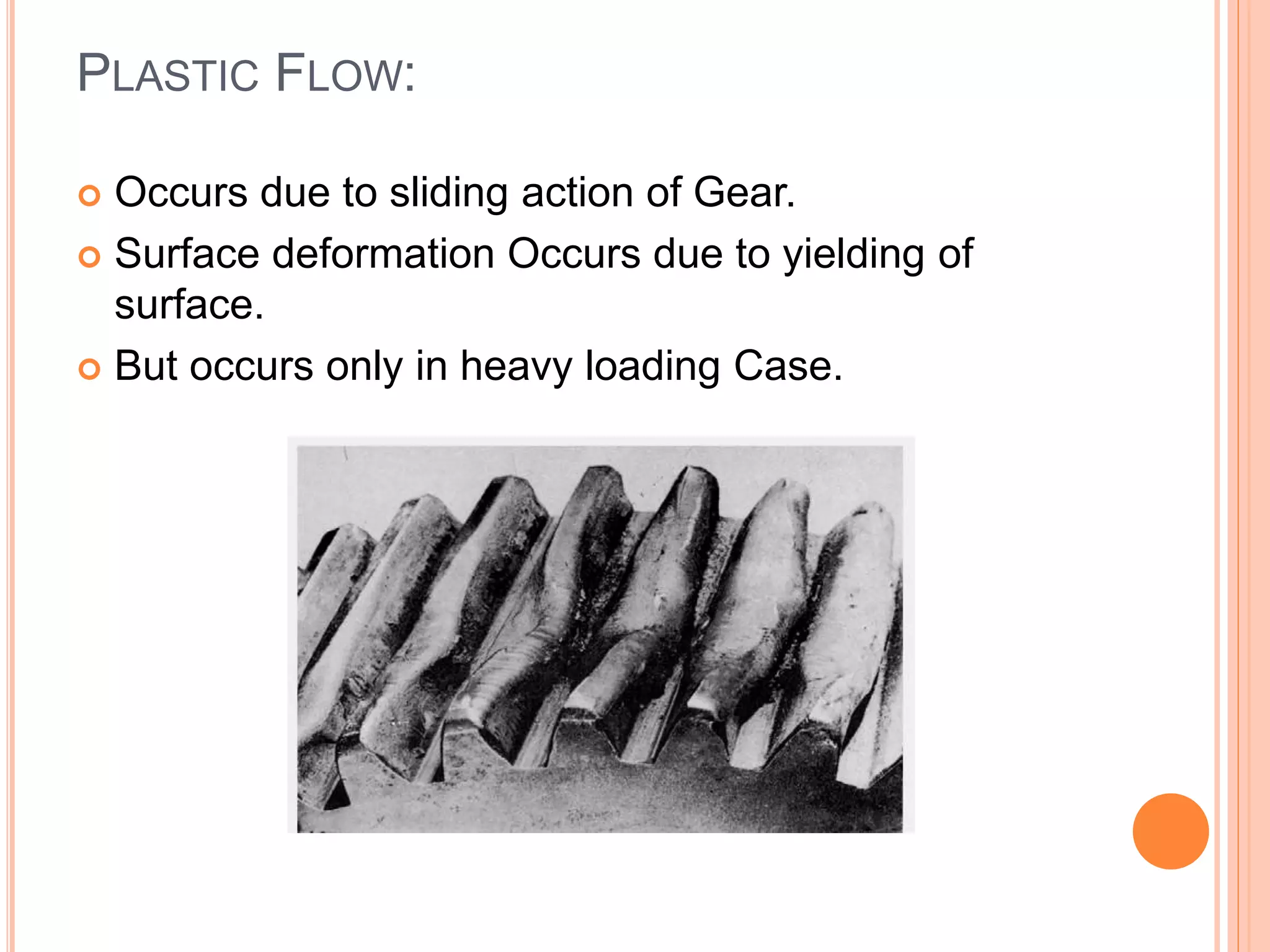

This document provides an overview of different types of gears including their key components and terminology. It discusses common gear types like spur gears, helical gears, bevel gears, and worm gears. For each type it provides examples of advantages and disadvantages as well as typical applications. The document also discusses gear materials and common modes of gear failure such as scoring, wear, pitting, plastic flow, and tooth fracture.