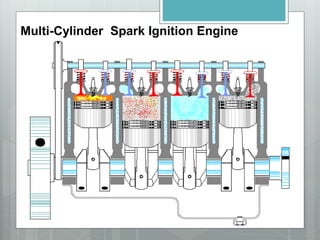

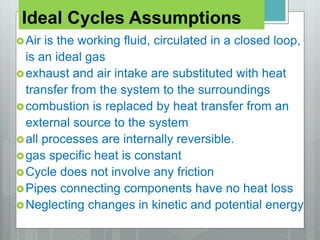

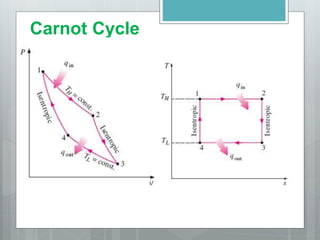

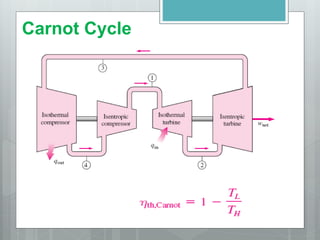

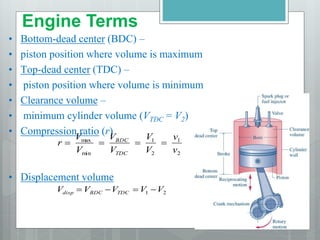

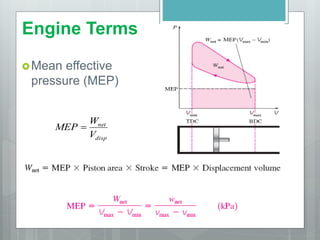

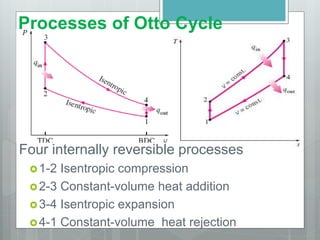

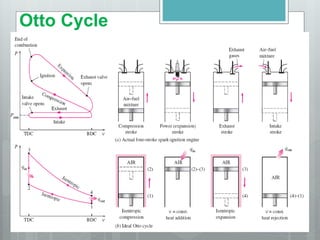

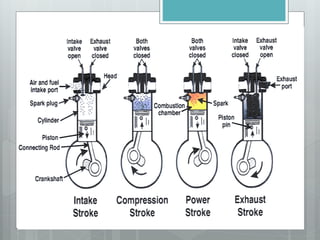

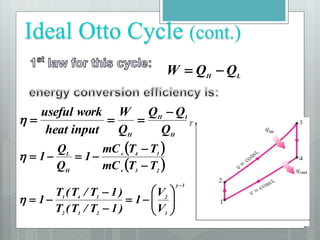

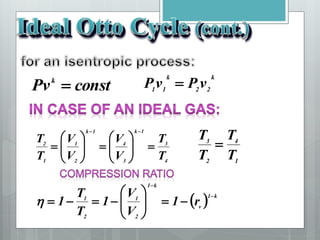

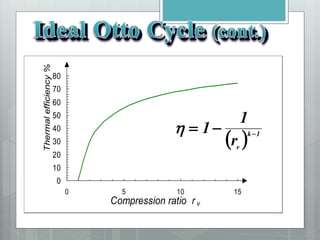

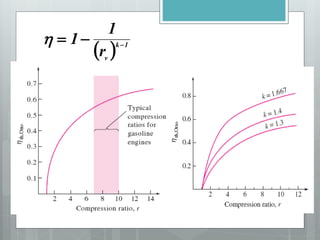

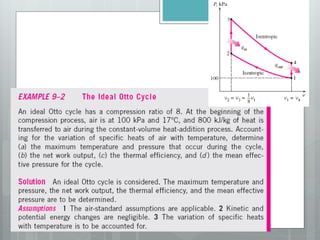

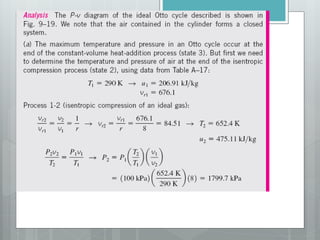

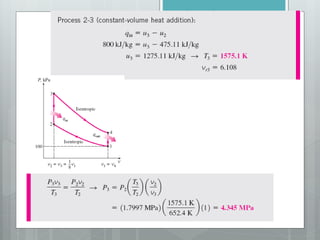

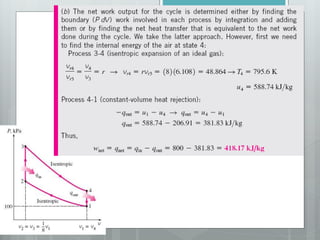

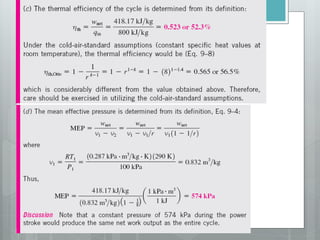

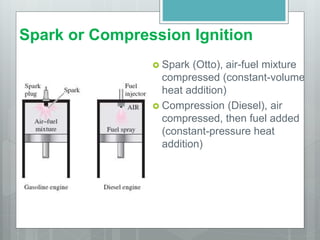

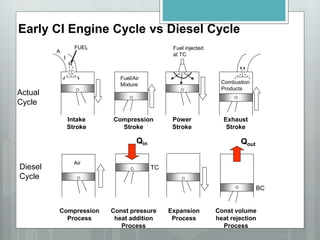

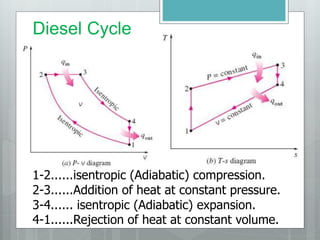

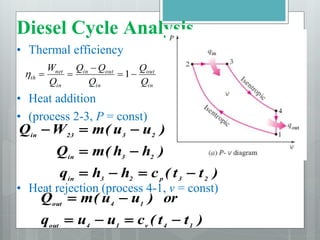

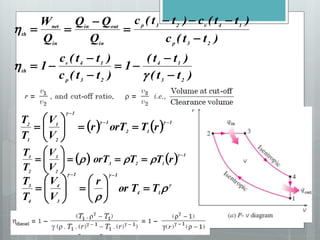

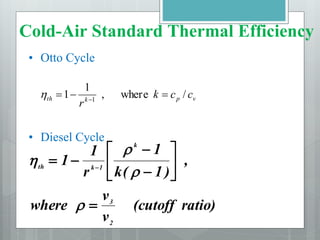

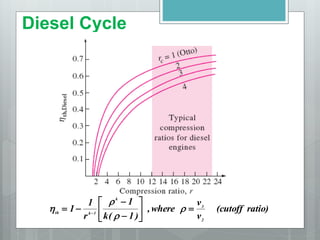

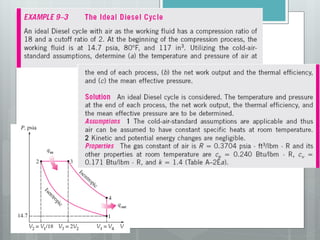

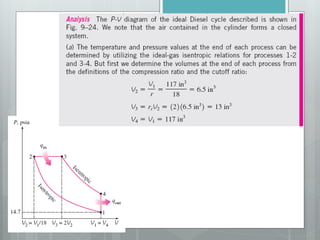

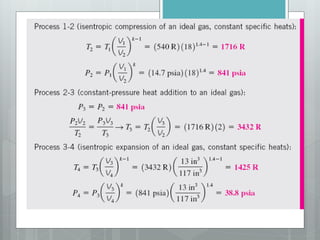

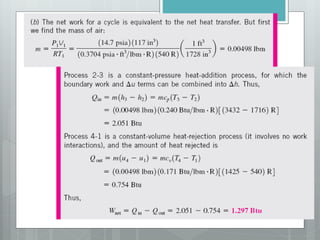

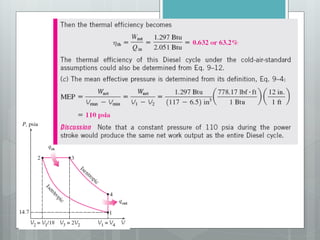

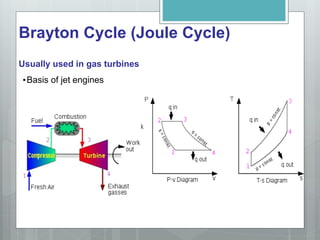

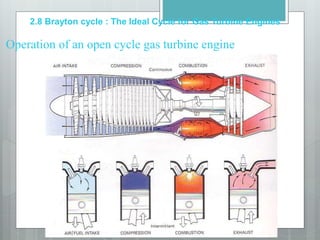

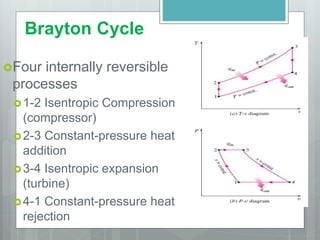

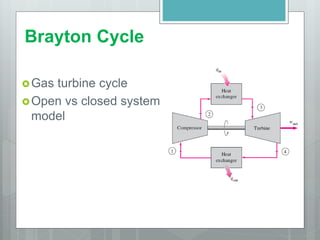

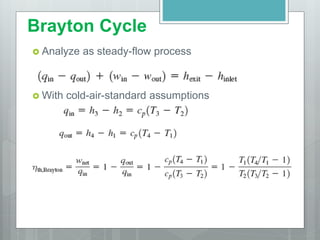

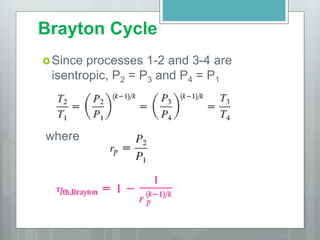

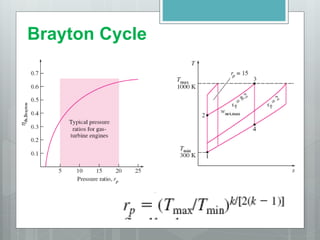

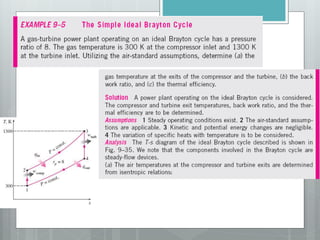

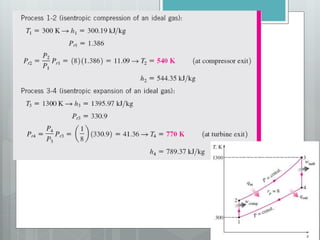

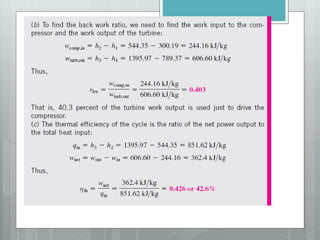

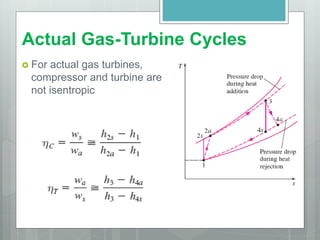

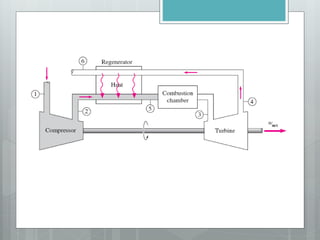

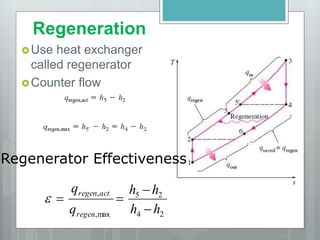

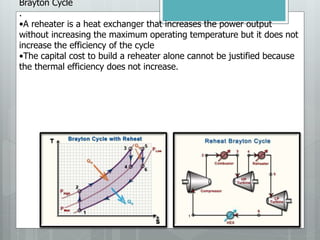

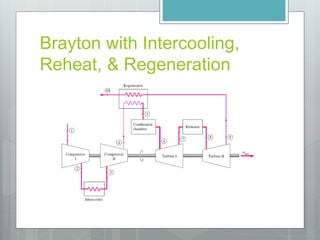

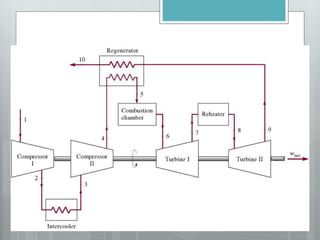

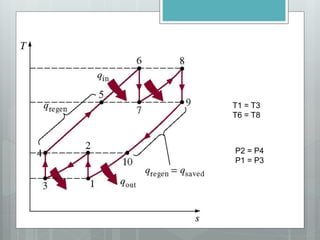

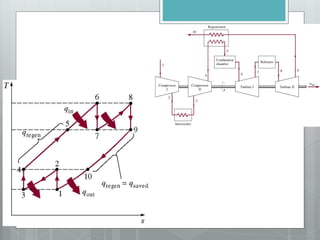

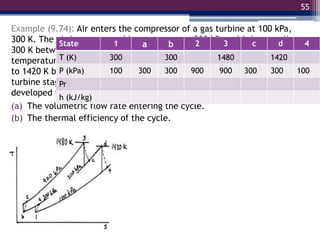

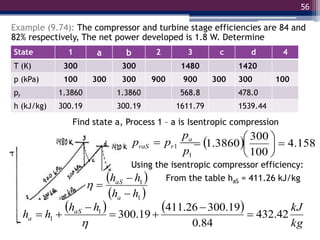

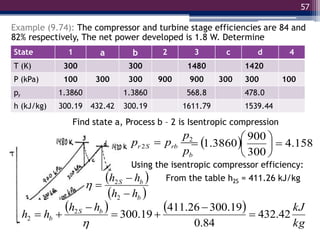

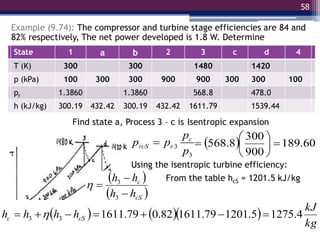

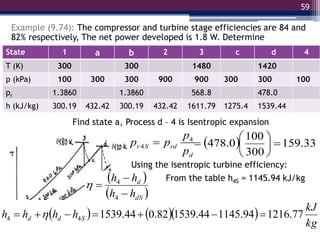

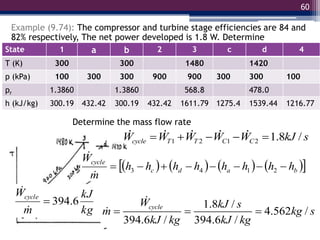

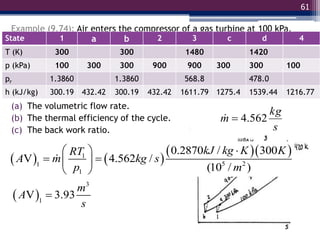

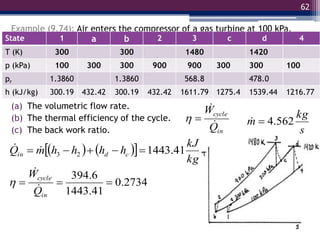

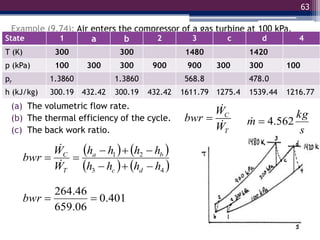

This document describes several gas power cycles including ideal cycles like the Otto cycle, Diesel cycle, and Brayton cycle as well as actual engine cycles. It provides details on the assumptions and processes of each ideal cycle. The Otto cycle involves four internally reversible processes: isentropic compression, constant-volume heat addition, isentropic expansion, and constant-volume heat rejection. The Diesel cycle also involves four internally reversible processes but with compression ignition. The Brayton cycle is typically used in gas turbines and involves isentropic compression, constant-pressure heat addition, isentropic expansion, and constant-pressure heat rejection. Regeneration and intercooling can improve the efficiency of actual cycles.