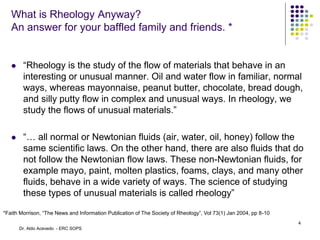

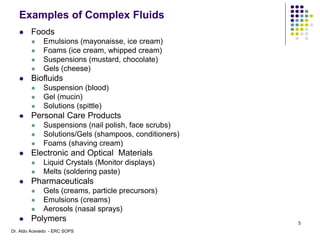

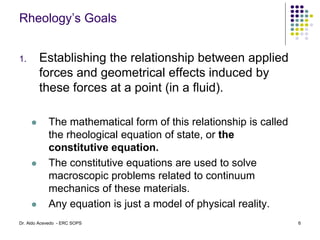

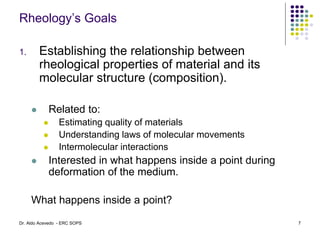

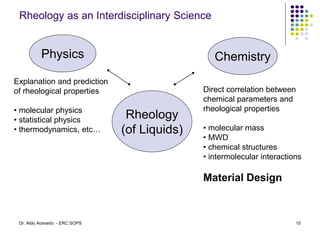

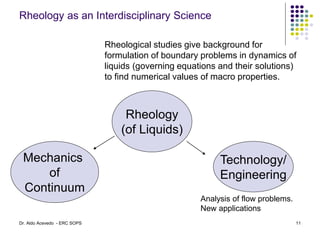

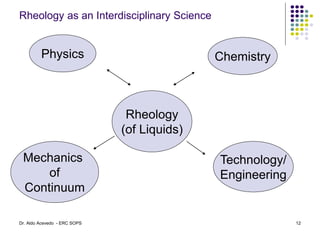

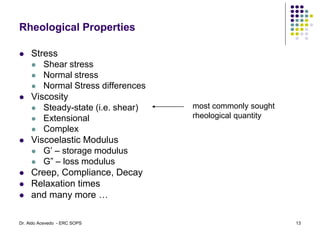

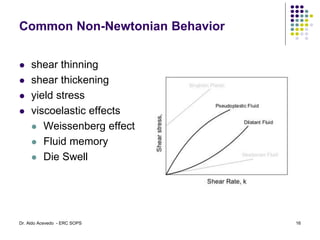

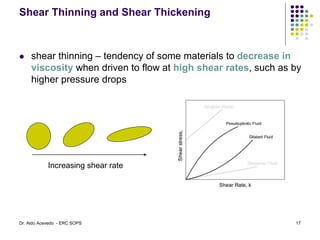

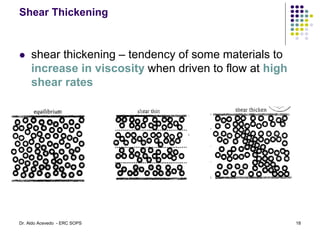

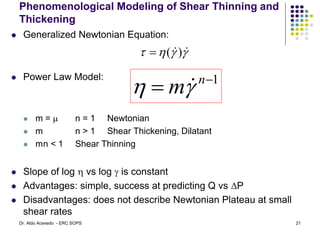

Rheology is the study of deformation and flow of matter. It examines how complex fluids flow in unusual ways compared to simple Newtonian fluids. Complex fluids include materials like mayonnaise, paints, and molten plastics. Rheology seeks to establish relationships between stress and strain in materials and understand how molecular structure influences flow properties. It is an interdisciplinary field that incorporates physics, chemistry, and continuum mechanics. Common non-Newtonian behaviors studied in rheology include shear thinning, shear thickening, yield stress, and viscoelasticity.

![Modeling of Shear Thinning and Thickening

Carreau-Yasuda Model

a – affects the shape of the transition region

l – time constant determines where it changes from constant to power

law

n – describes the slope of the power law

0, ∞ - describe plateau viscosities

Advantages: fits most data

Disadvantages: contains 5 parameters, do not give molecular

insight into polymer behavior

a

n

a

1

0

]

)

(

1

[

)

(

l

22

Dr. Aldo Acevedo - ERC SOPS](https://image.slidesharecdn.com/i-230126103753-496b52db/85/I-_Introduction_to_Rheology-ppt-22-320.jpg)