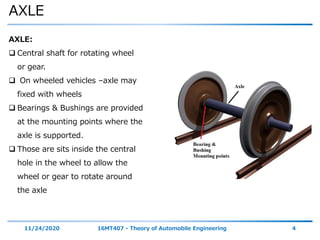

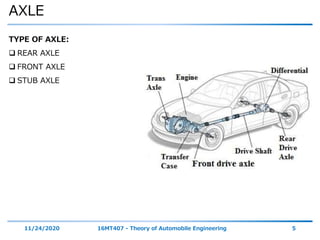

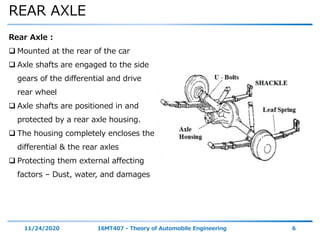

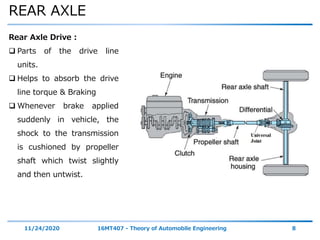

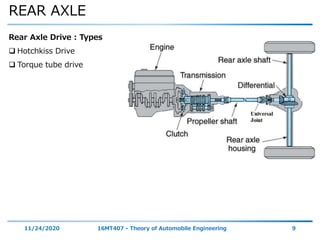

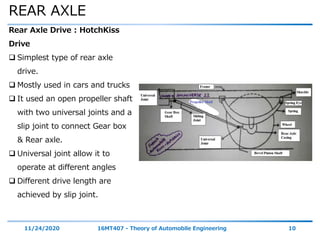

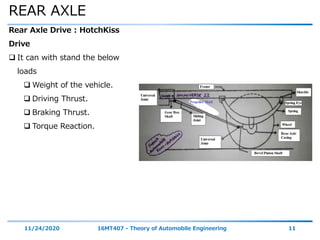

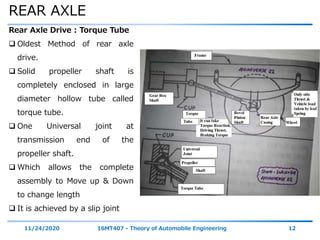

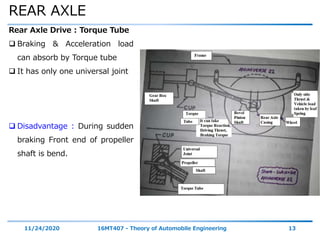

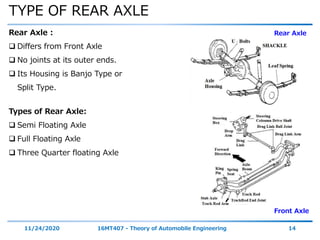

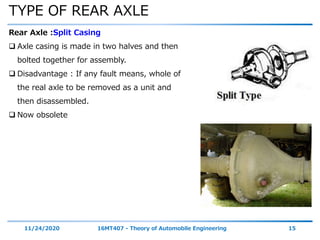

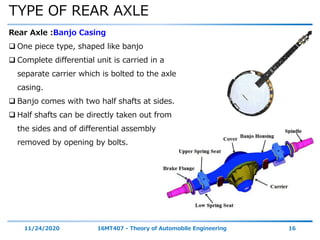

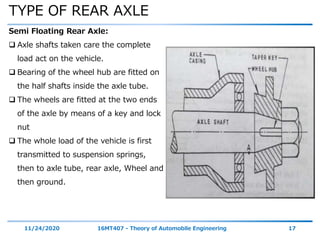

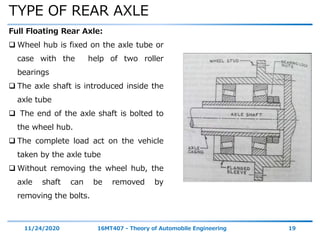

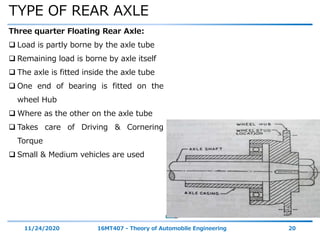

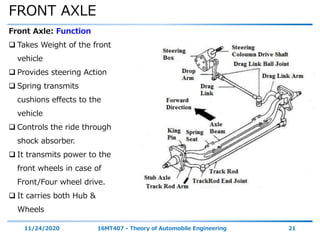

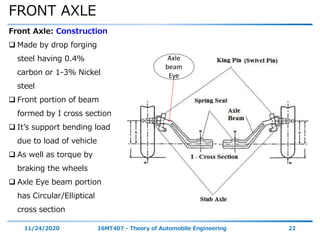

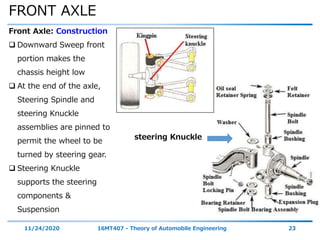

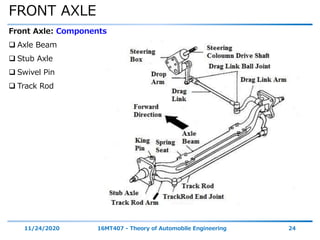

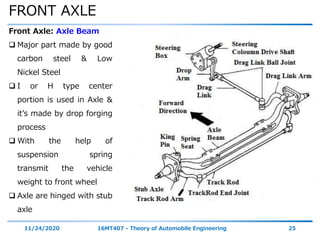

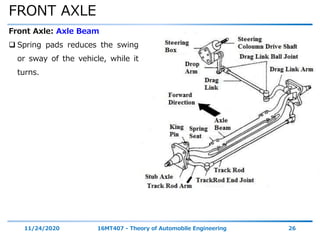

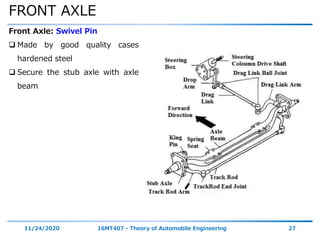

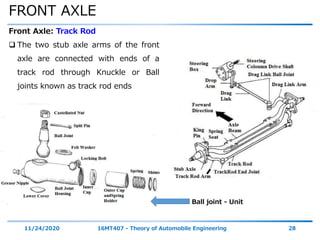

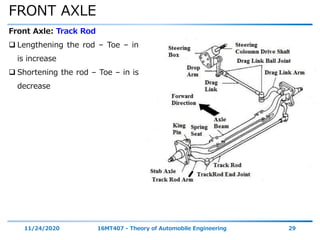

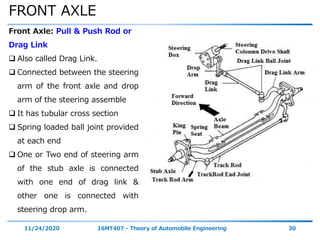

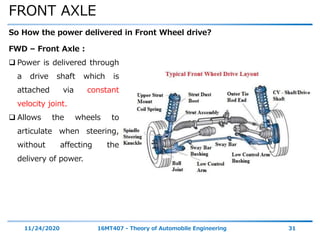

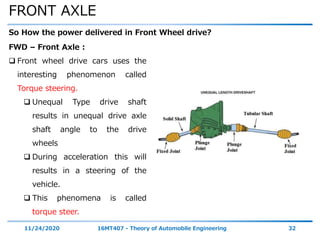

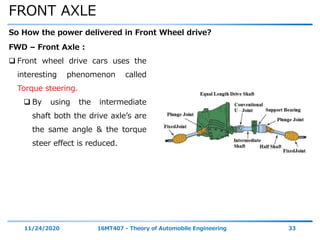

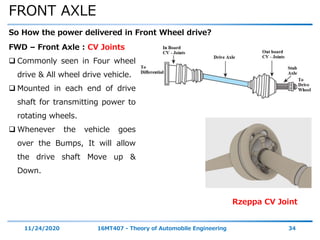

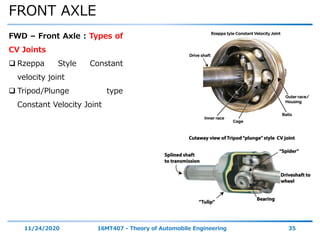

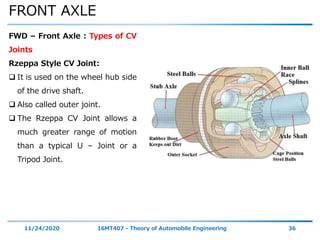

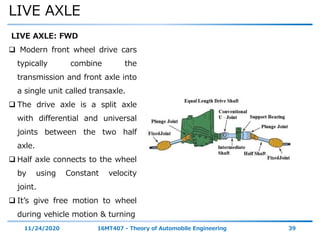

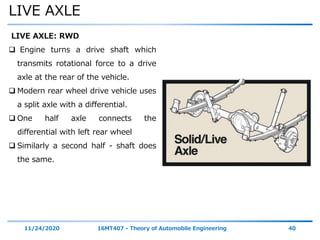

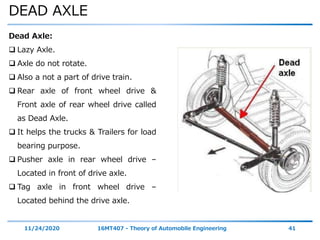

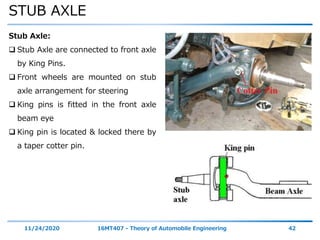

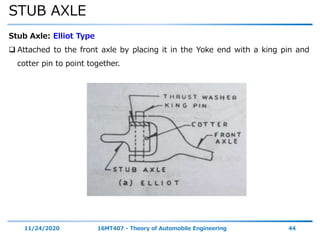

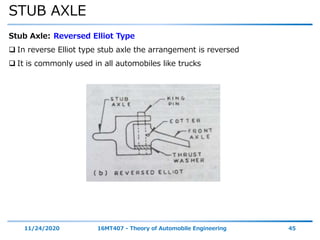

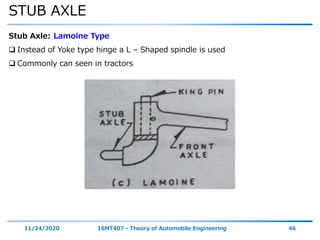

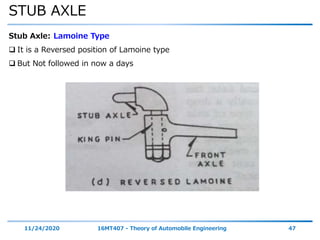

The document discusses various axle systems used in vehicles. It describes the construction and function of rear axles, front axles, and stub axles. Rear axles are mounted at the rear of the vehicle and use axle shafts to transmit power from the differential to the rear wheels. Front axles provide steering action and support the front of the vehicle. Stub axles connect the wheels to the front and rear axles. The document outlines different types of rear axles including semi-floating, full-floating, and three-quarter floating designs.