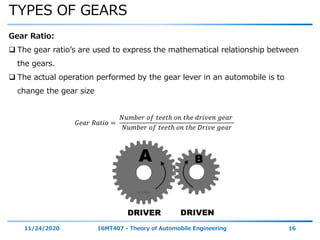

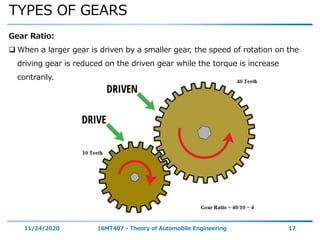

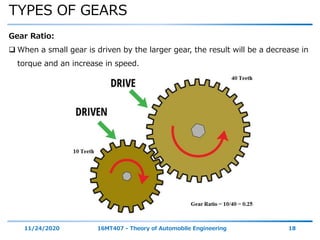

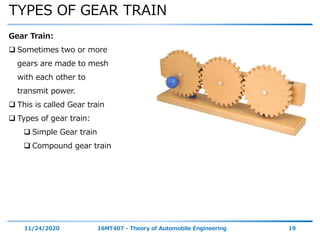

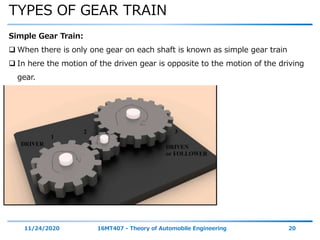

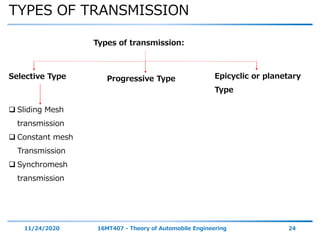

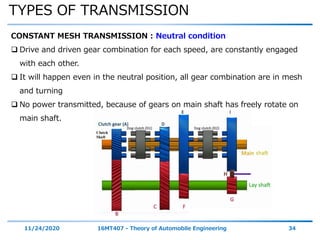

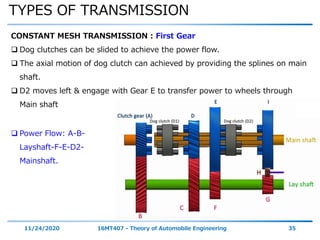

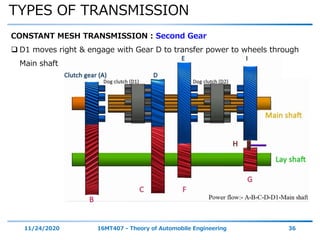

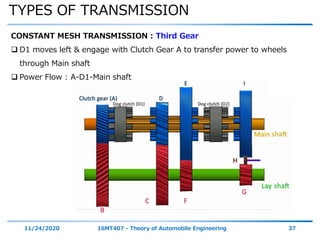

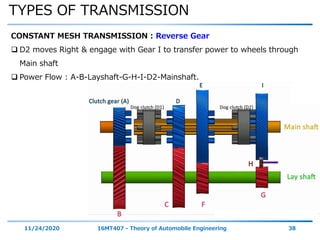

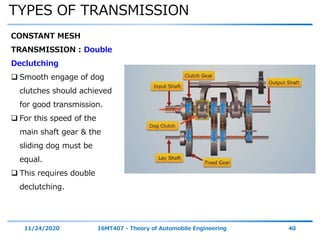

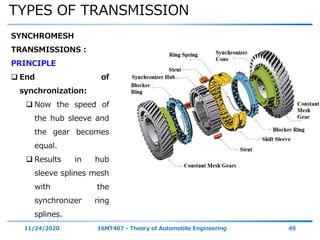

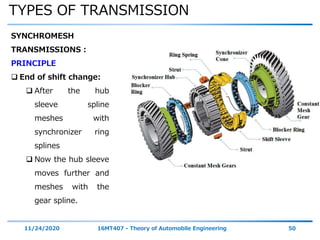

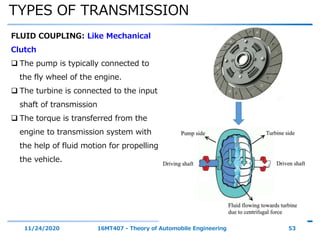

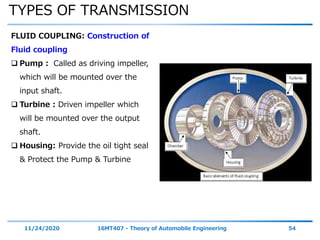

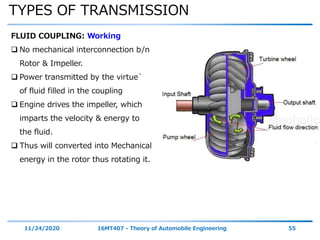

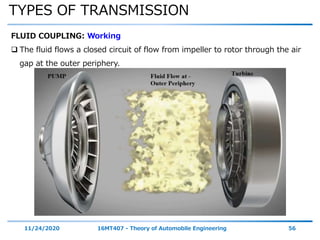

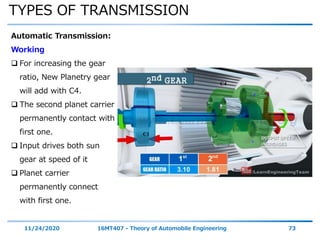

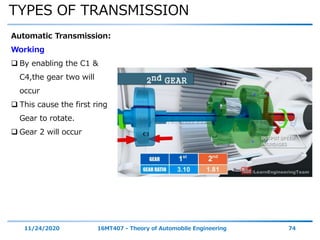

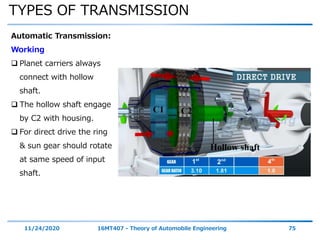

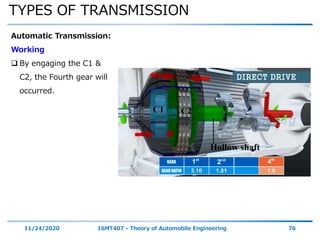

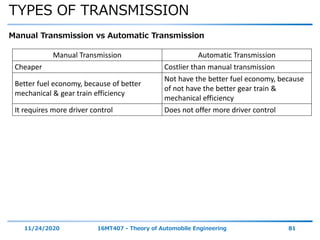

This document is an educational material from Sri Krishna College of Engineering and Technology focused on transmission systems in automobiles, detailing the importance, functions, and types of transmission systems and gears. It covers concepts such as gear ratios, gear trains, different types of gears, and specific transmission types like sliding mesh and synchromesh. Additionally, it explains the principles and mechanics involved in each transmission type, emphasizing their advantages and disadvantages.

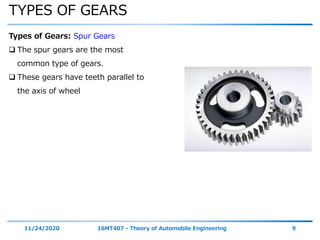

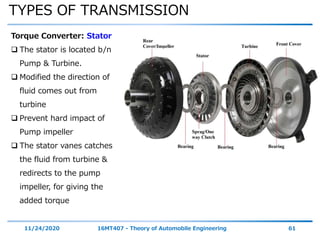

![TYPES OF GEARS

11/24/2020 16MT407 - Theory of Automobile Engineering 8

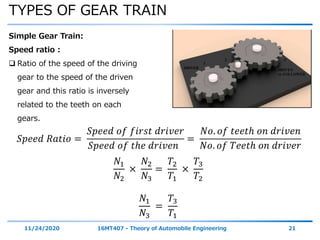

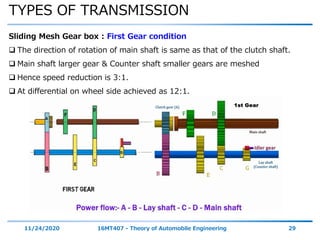

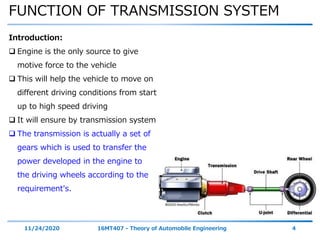

Introduction:

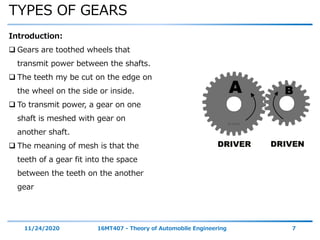

When one gear turns, then it’s teeth

forces the other gear to turn.

The gear that does the turning is the

driving gear.[A - Gear]

The gear that is forced to turn is the

driven gear.[B – Gear]](https://image.slidesharecdn.com/transmissionsystem-201124100255/85/Automotive-Transmission-system-8-320.jpg)