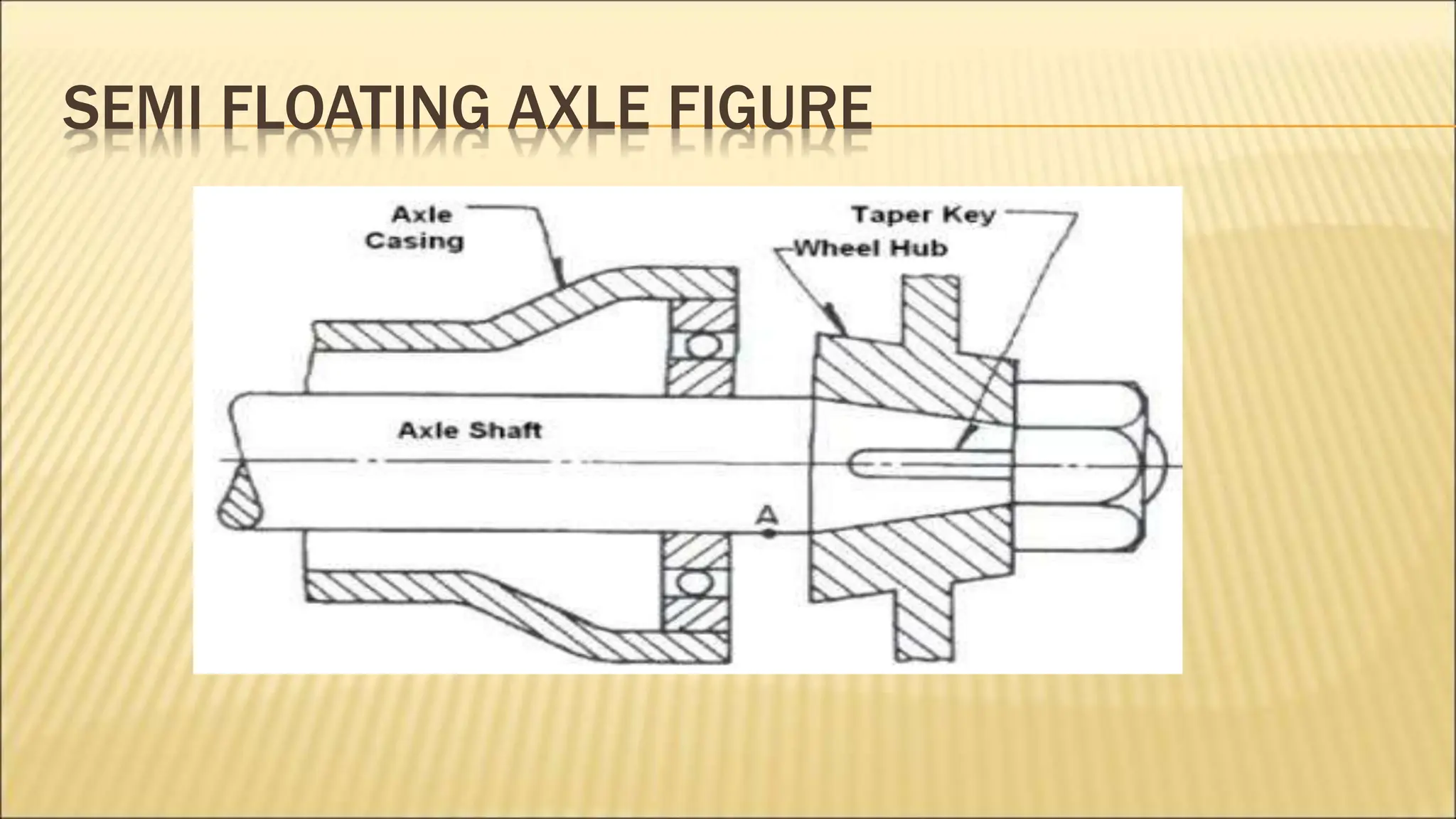

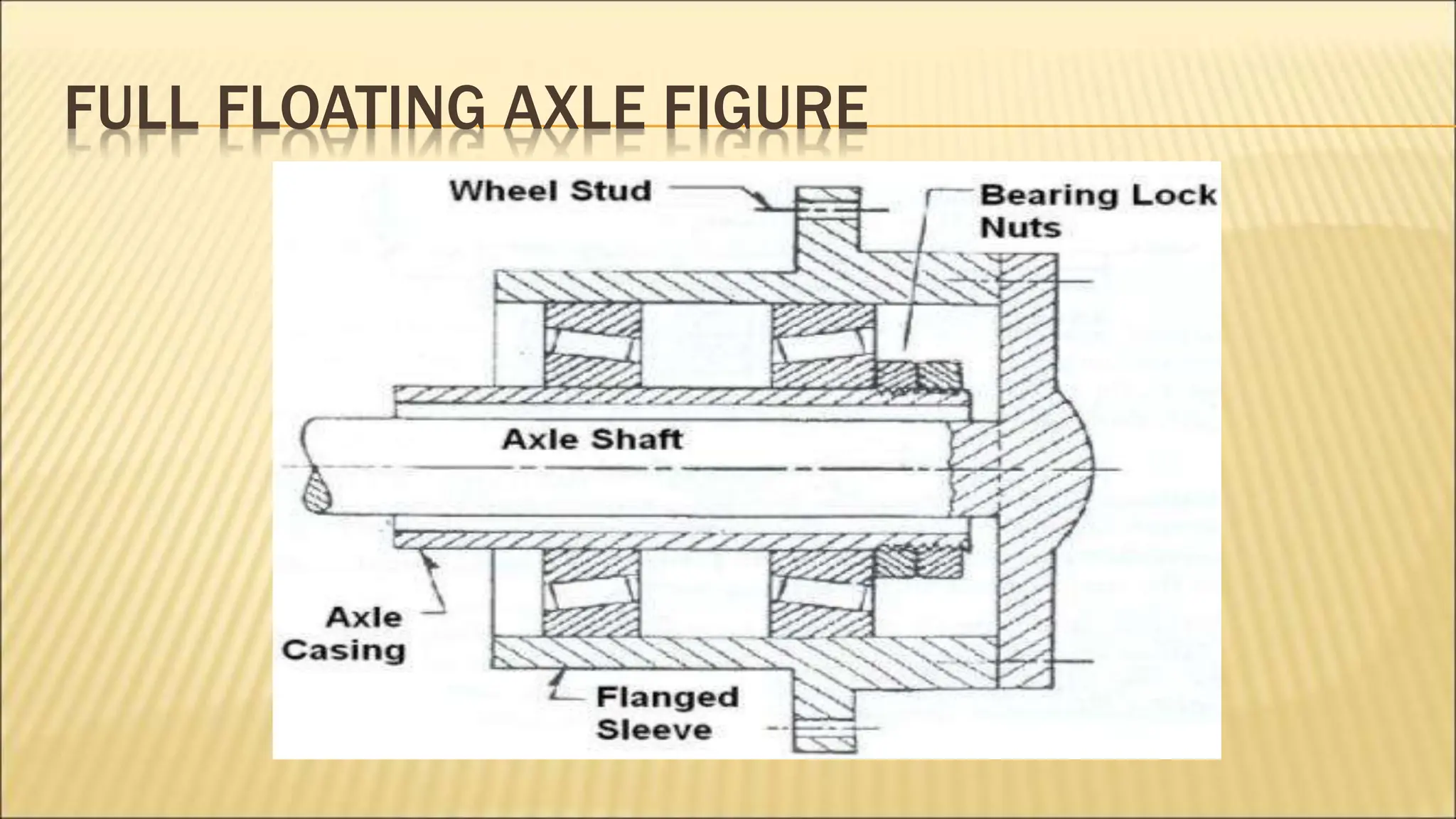

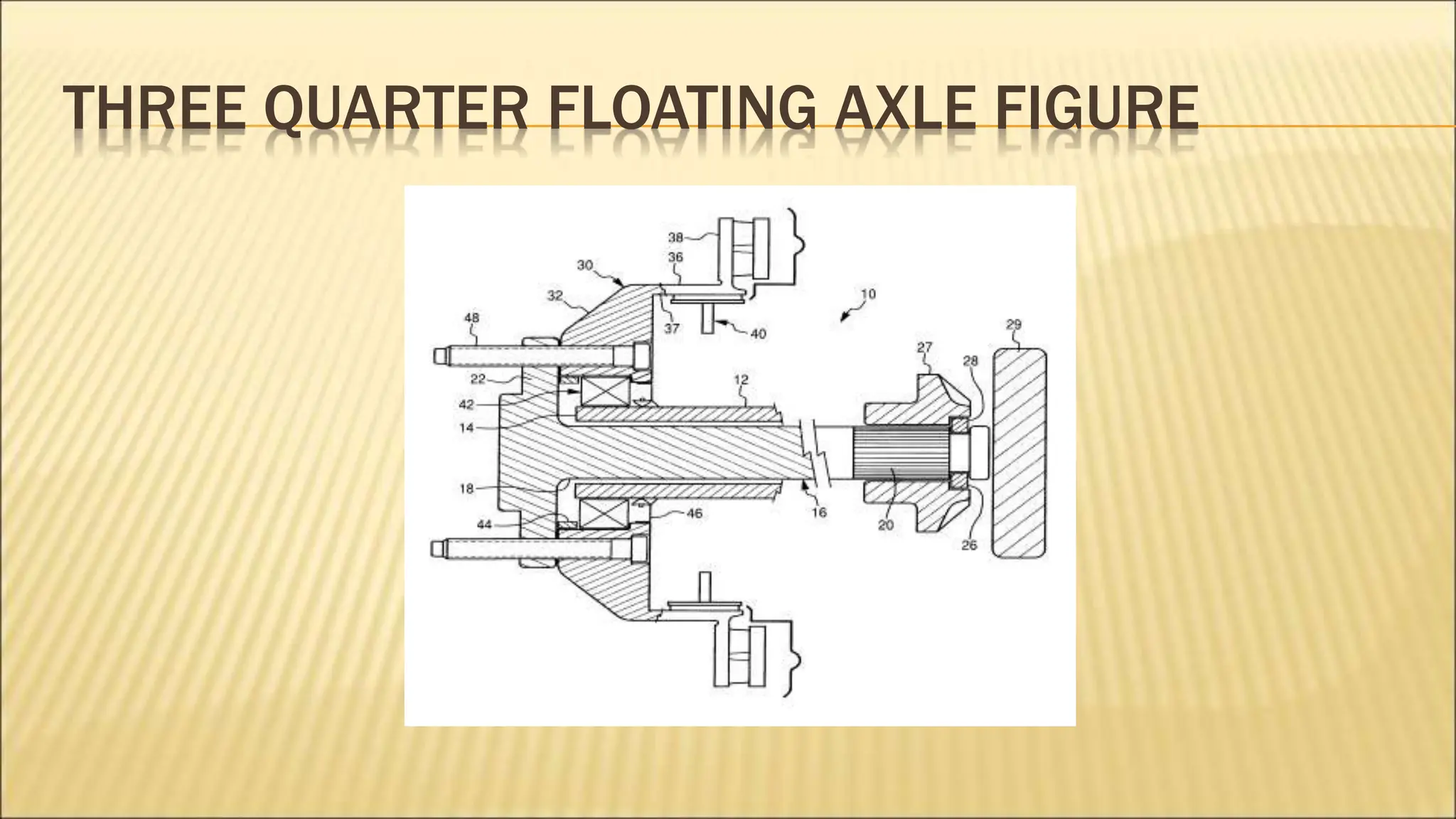

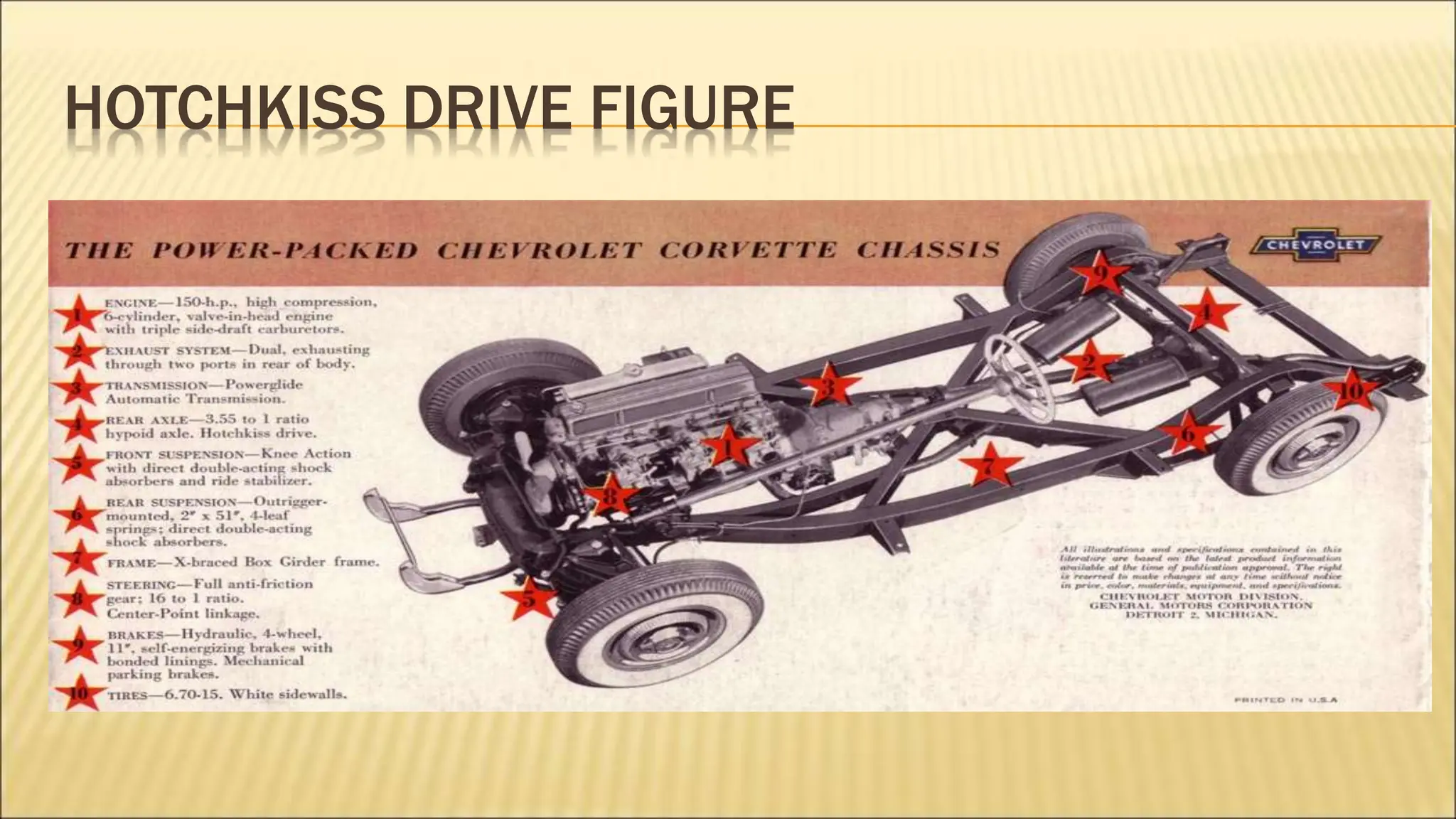

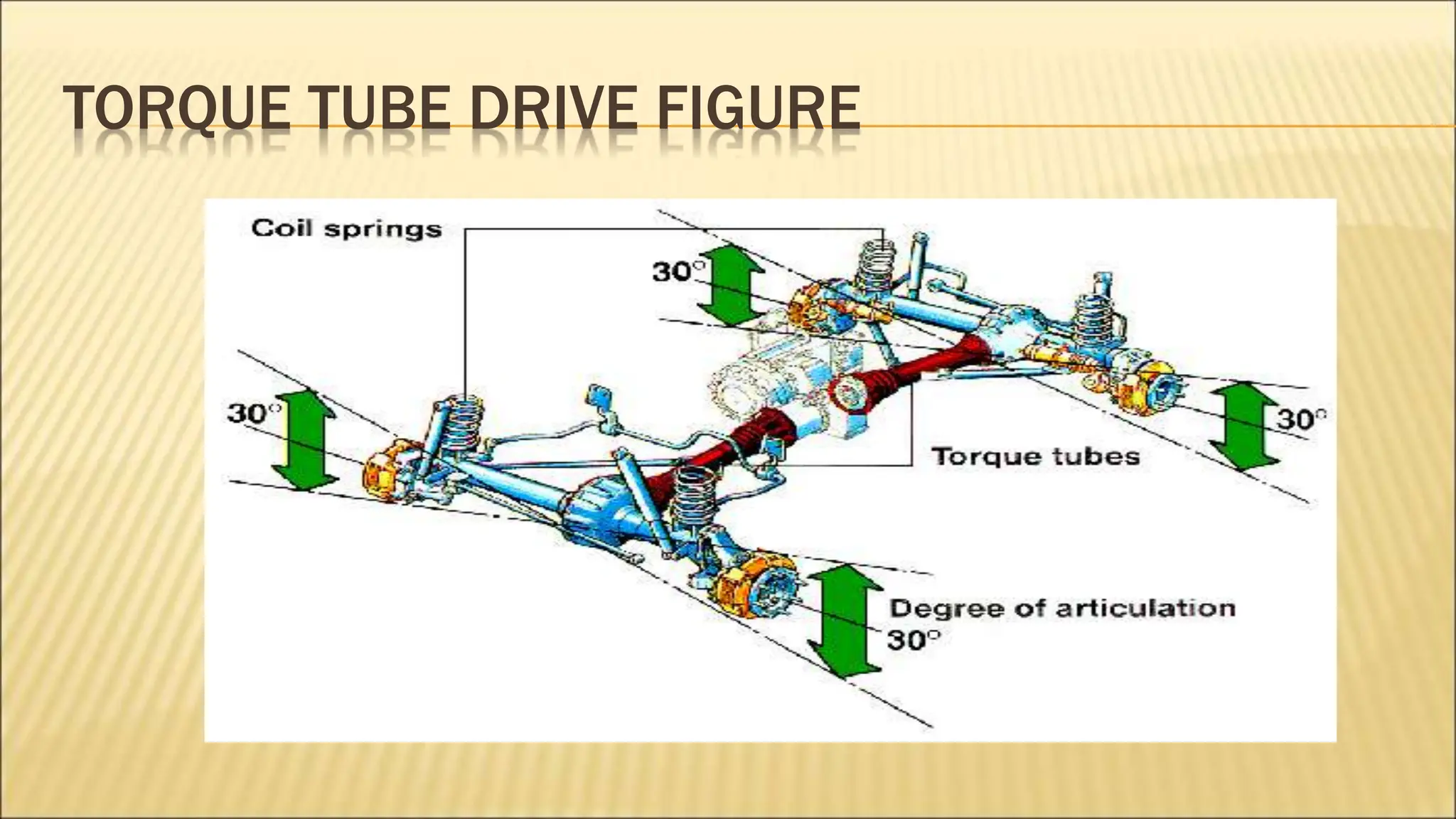

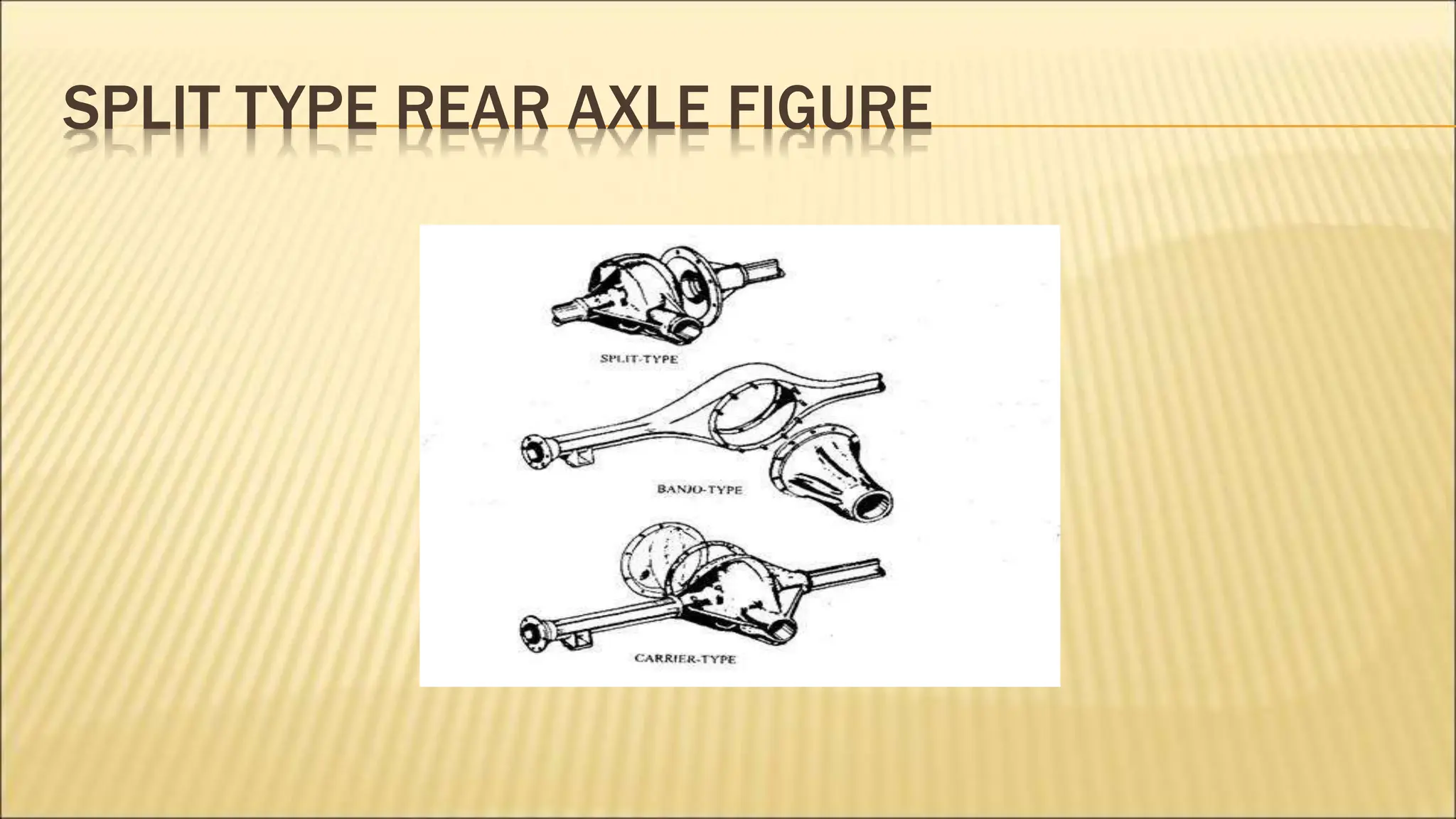

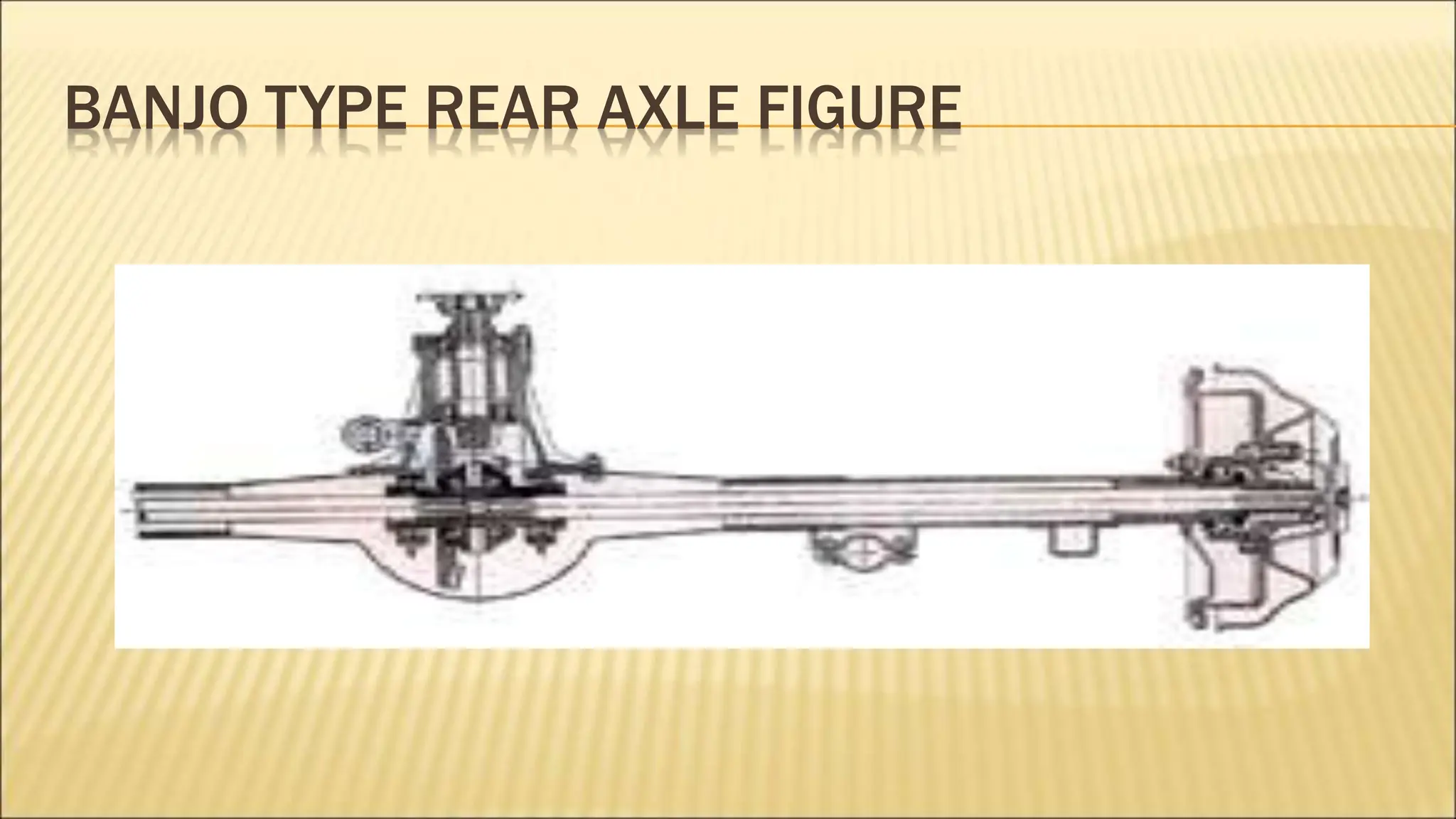

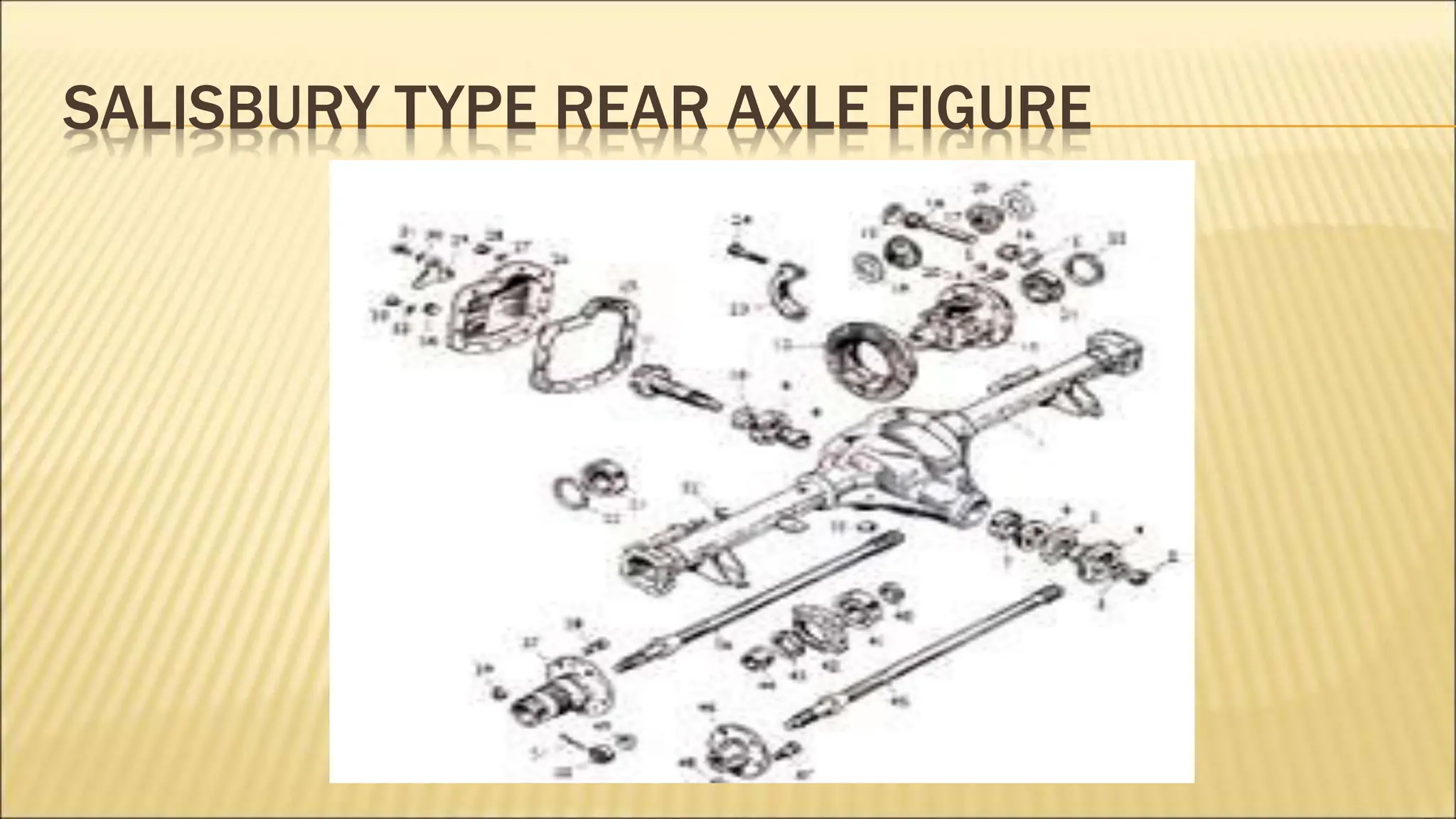

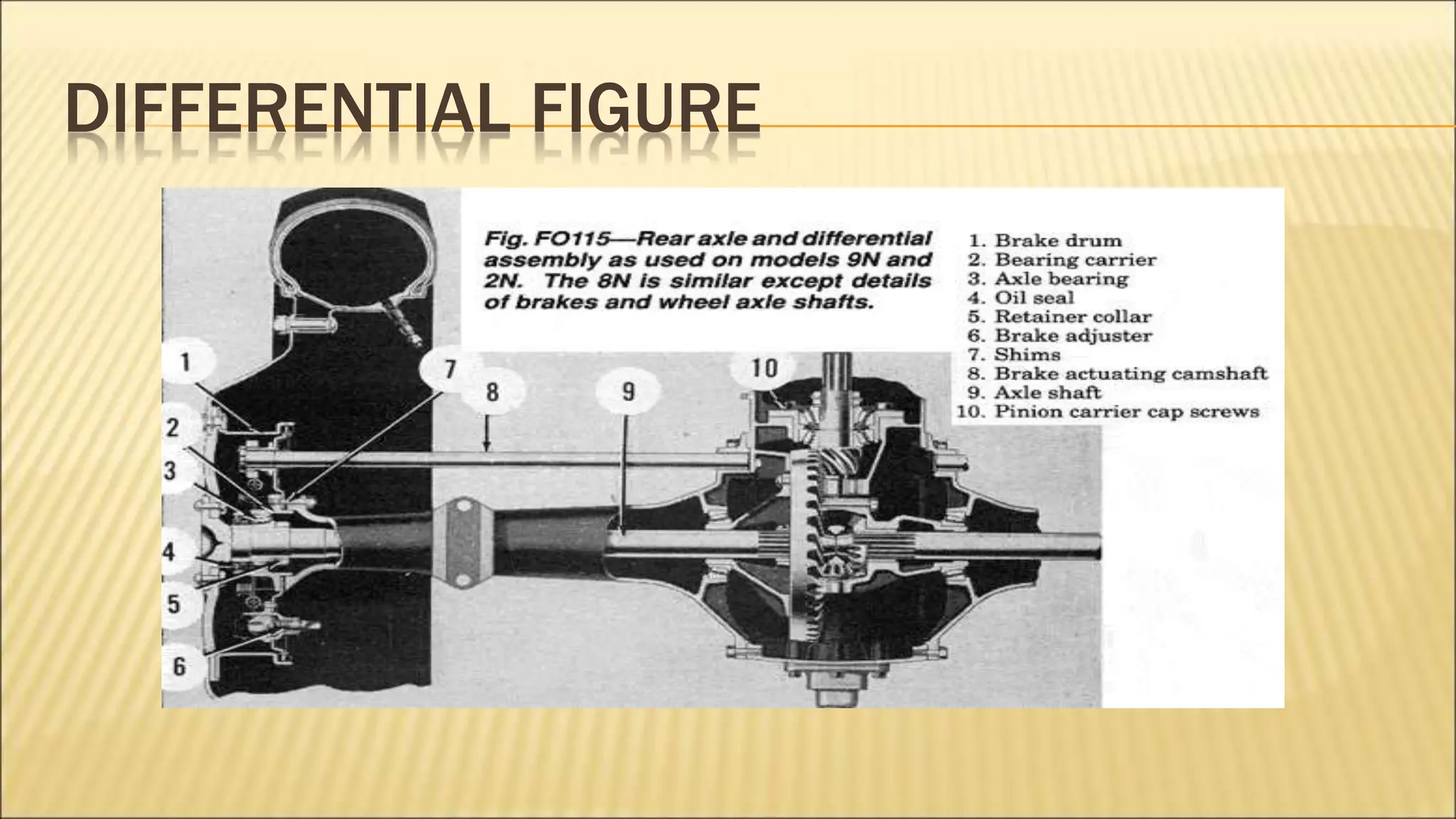

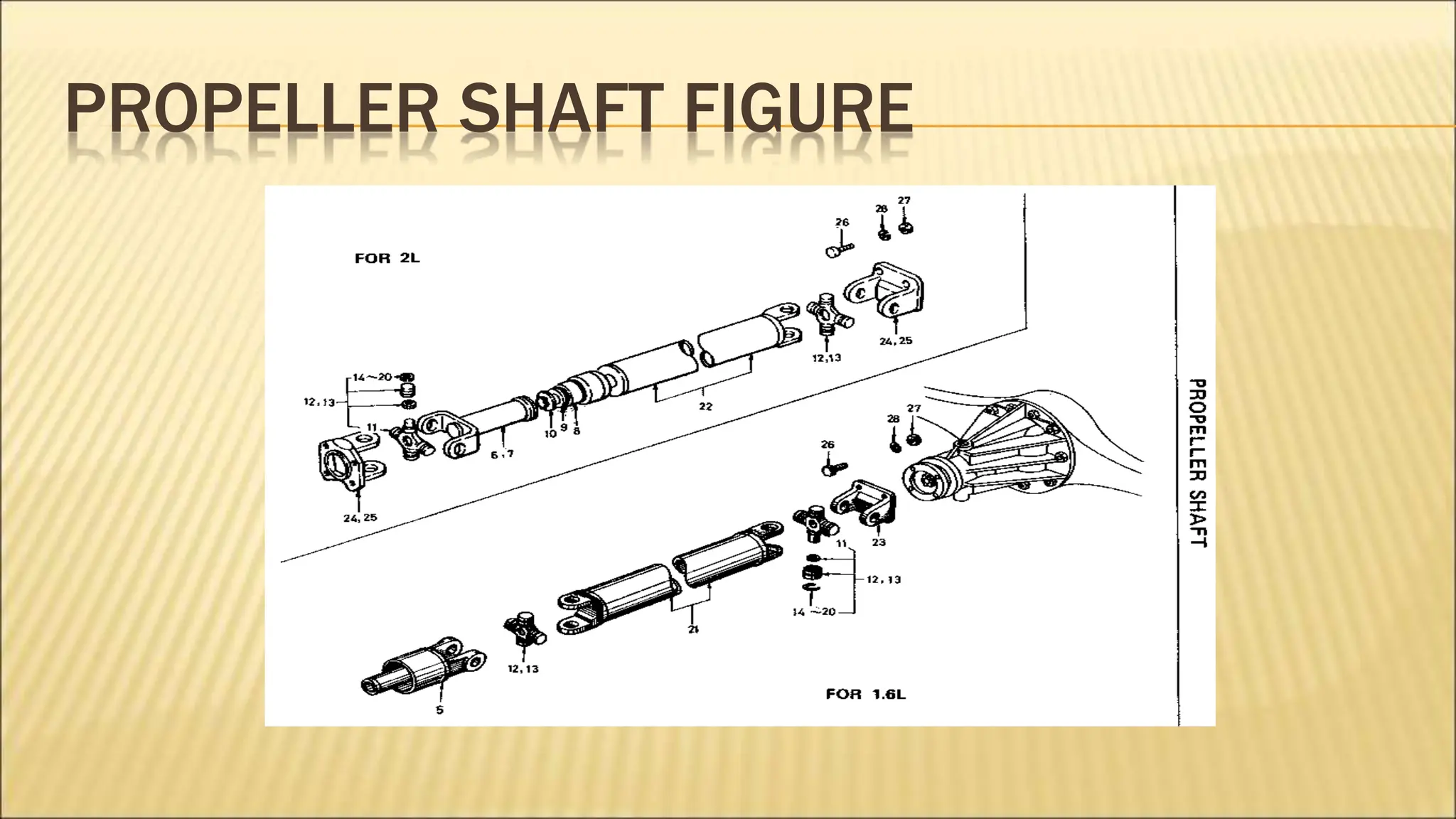

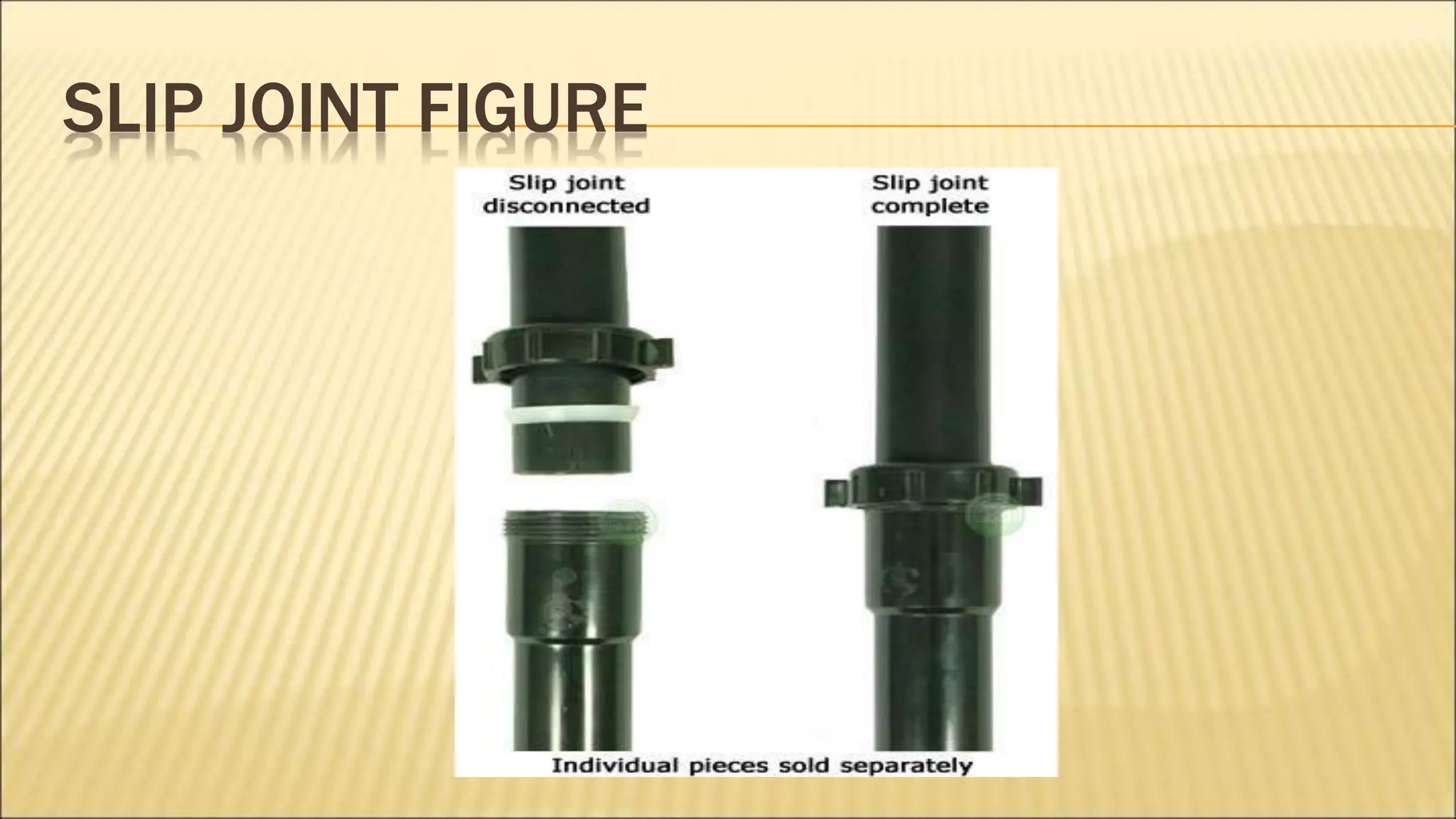

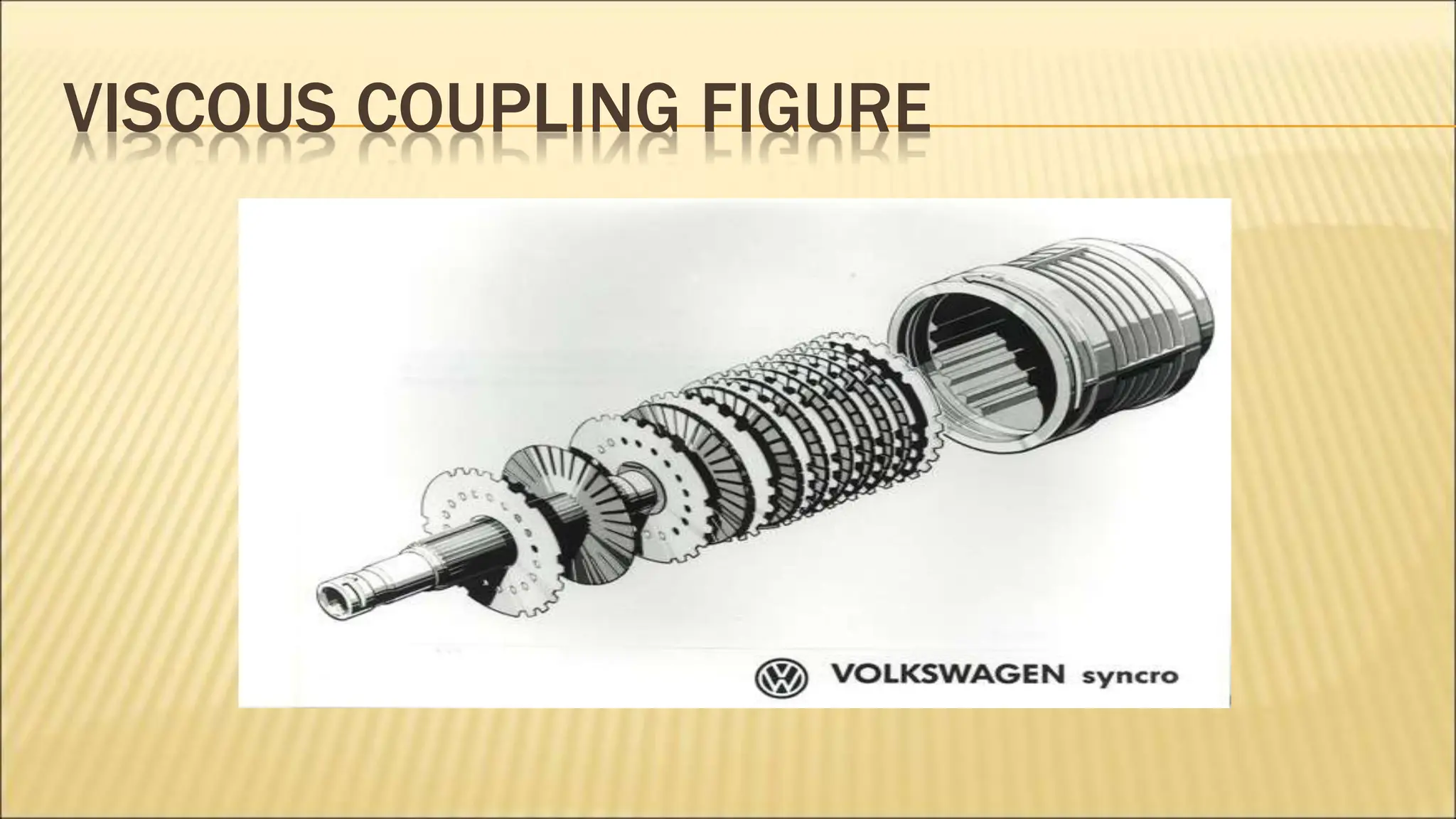

The document provides a comprehensive overview of rear axles and final drives in automobiles, detailing their construction, forces acting on them, types, and various components including propeller shafts and different gear types for final drives. It introduces the concept of different axle support designs, such as semi-floating, full-floating, and three-quarter floating, as well as methods of rear axle drives like Hotchkiss and torque tube drives. Additionally, it discusses the differential mechanism, types of gears, and advances in transmission systems, focusing on their functionalities and advantages.