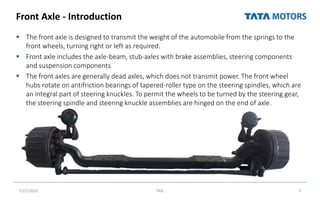

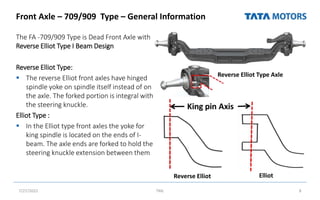

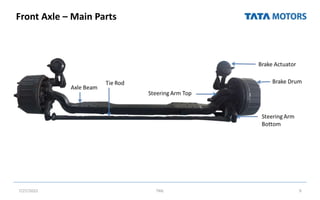

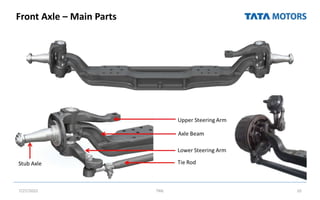

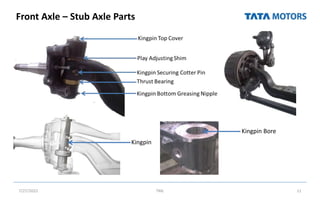

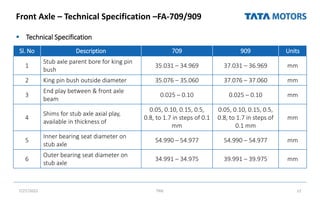

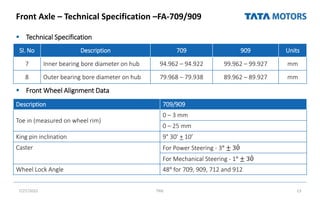

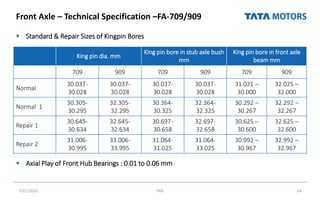

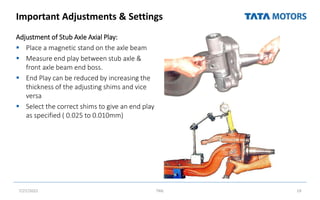

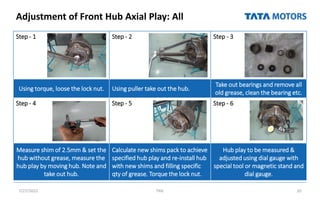

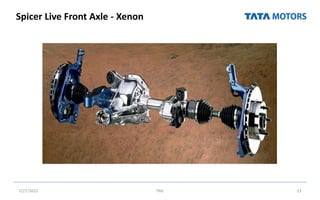

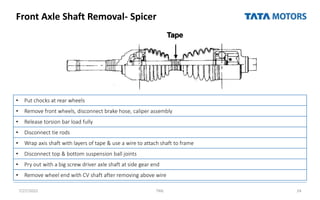

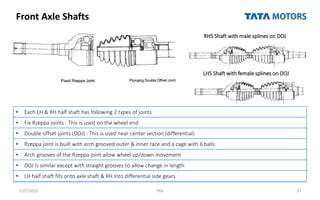

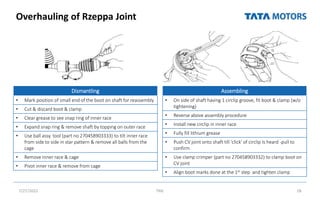

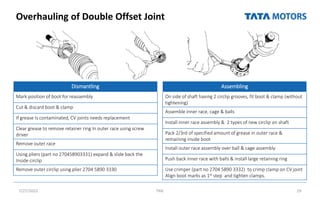

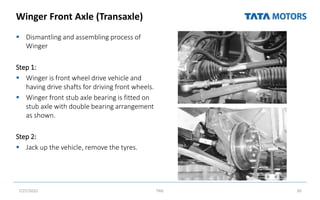

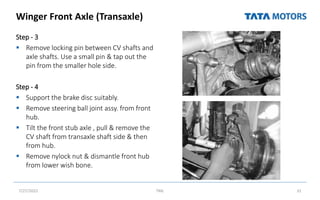

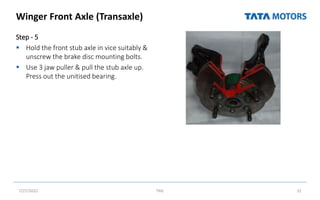

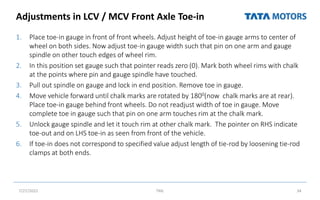

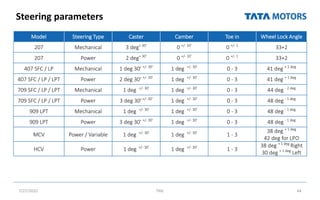

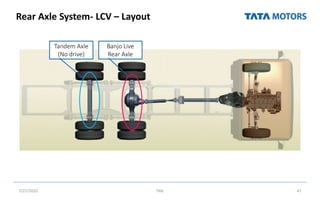

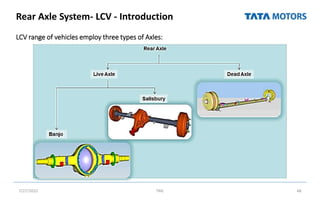

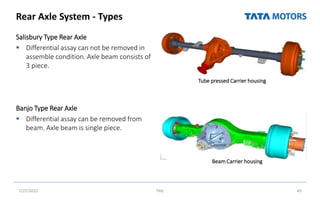

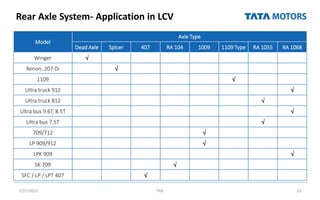

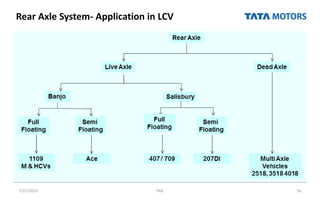

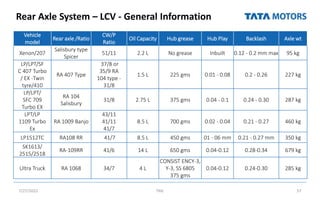

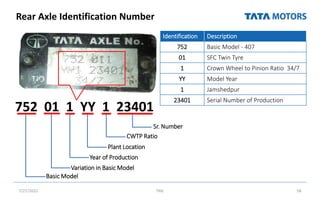

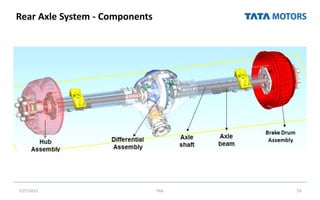

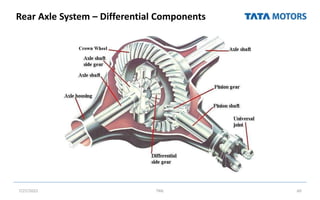

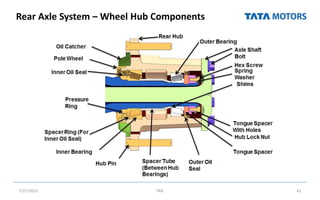

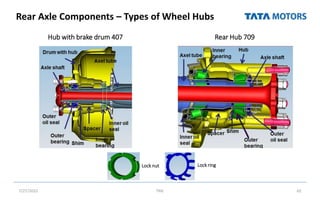

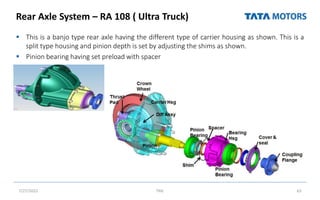

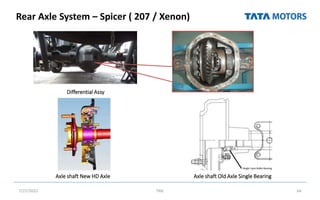

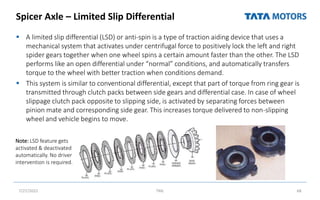

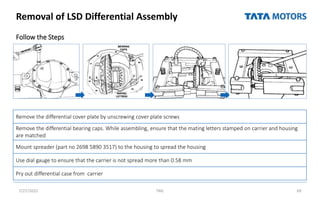

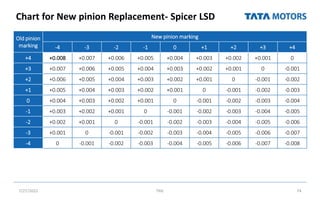

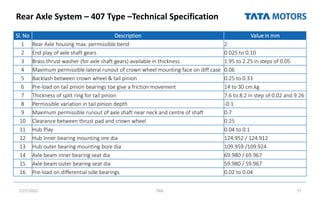

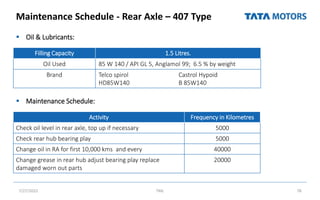

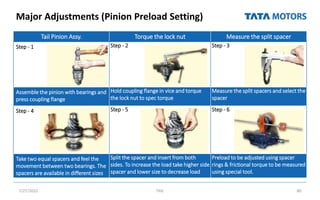

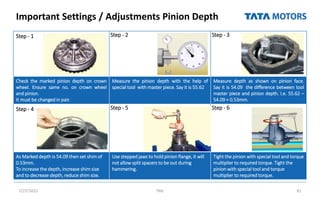

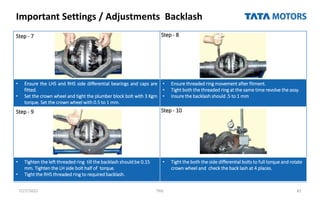

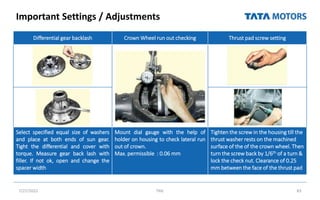

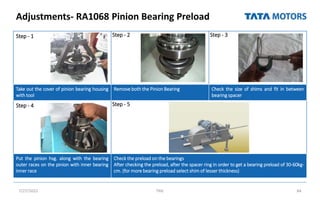

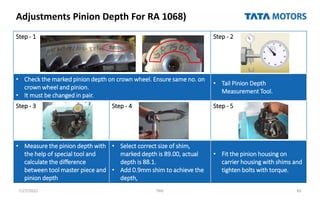

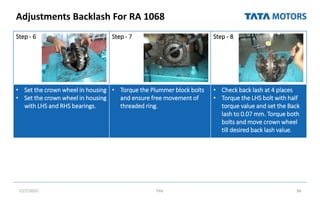

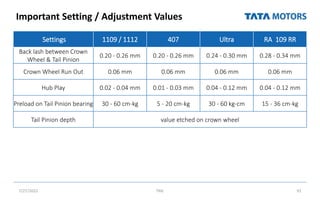

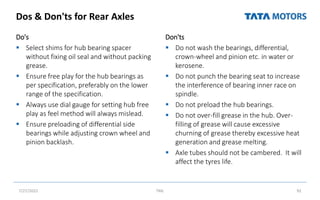

The document provides information on the front and rear axle systems for LCV vehicles. It discusses the objectives, agenda, and general information about the front axle 709/909 type. The document outlines the process for overhauling the front axle, including removal from the vehicle, inspection, and removal and assembly of wheel hub and stub axle components. It also discusses technical specifications, adjustments and settings for the front axle. For the rear axle, it provides information on the 407/709 type including removal, disassembly, inspection and reassembly processes.