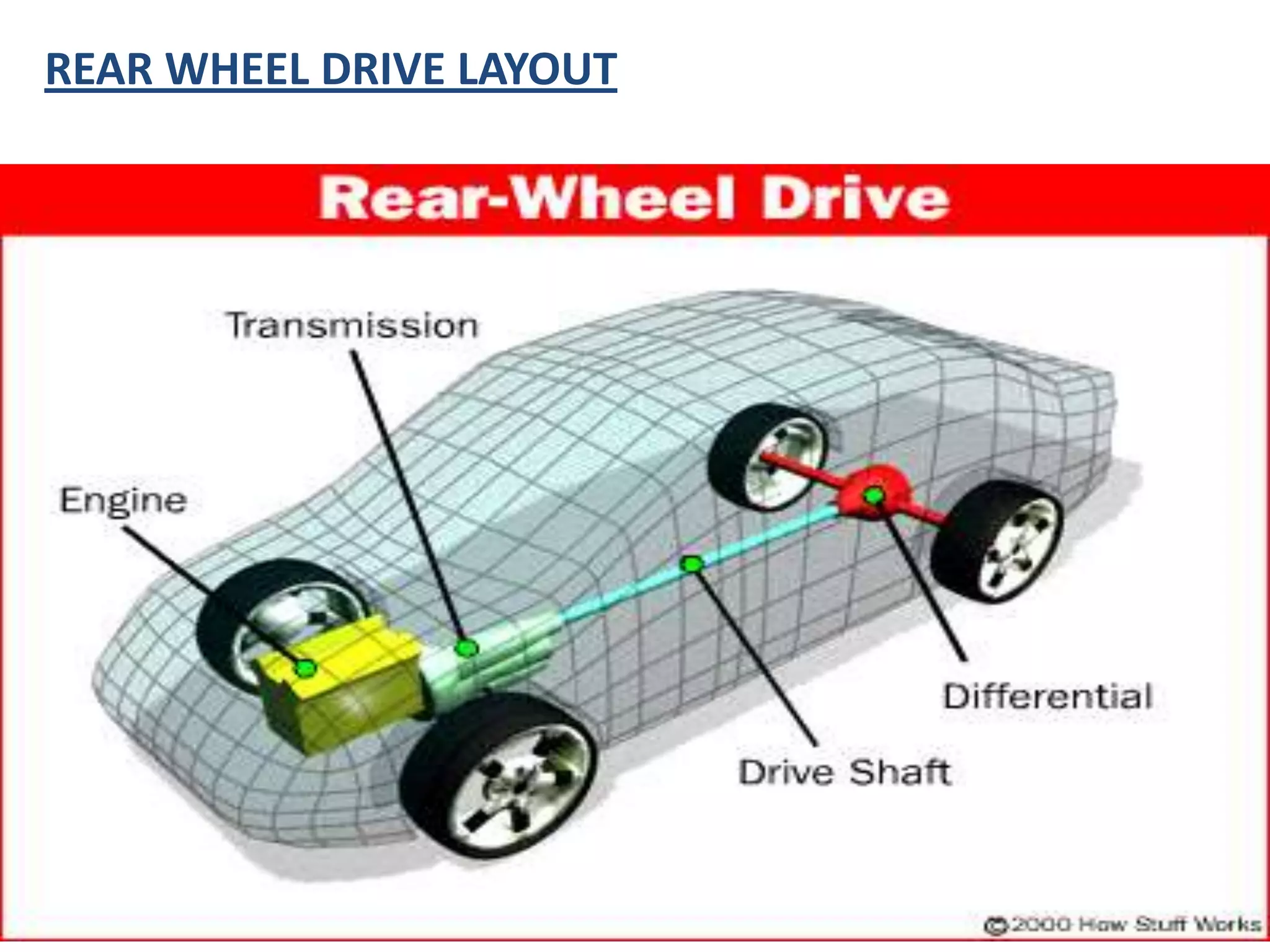

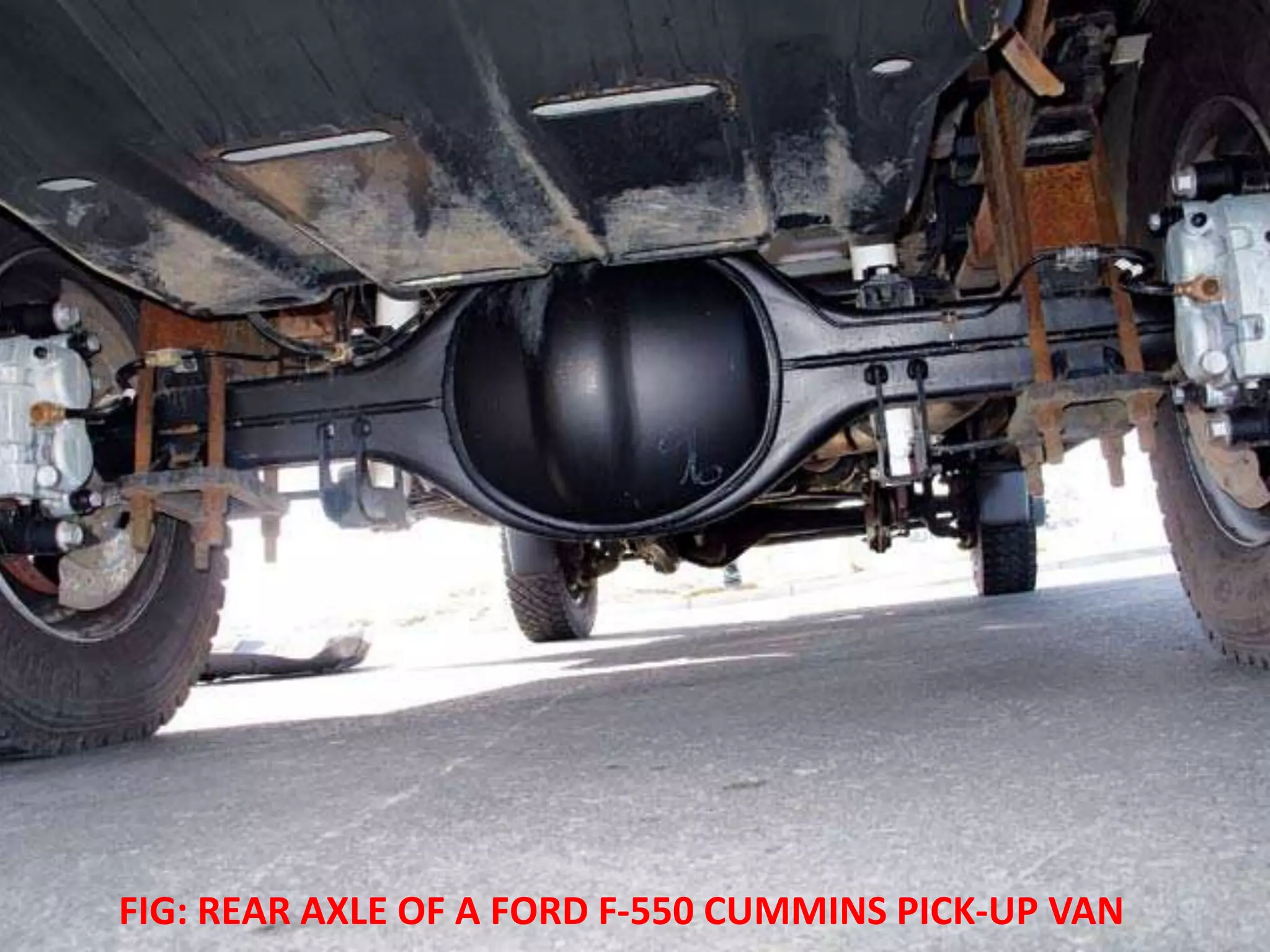

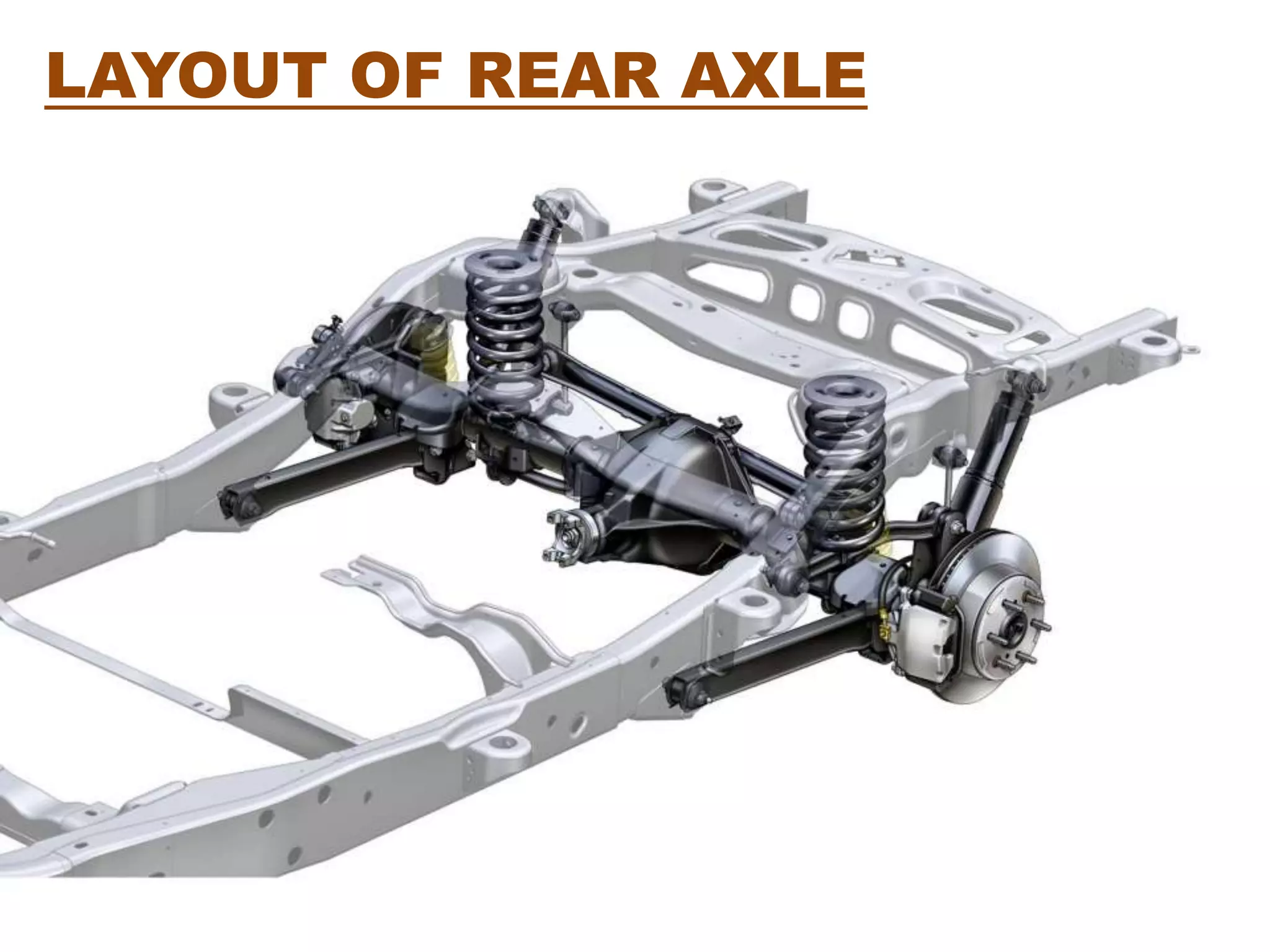

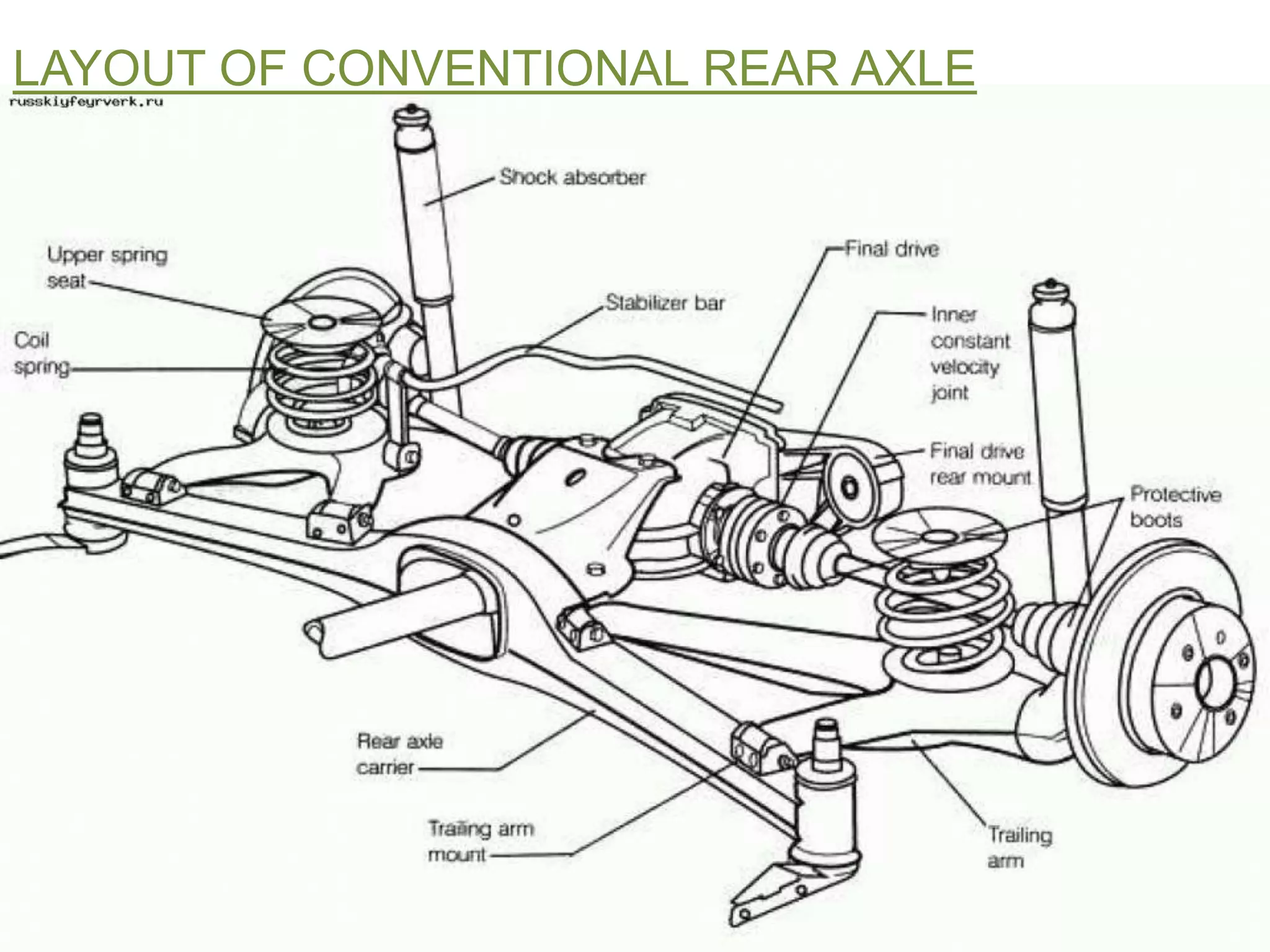

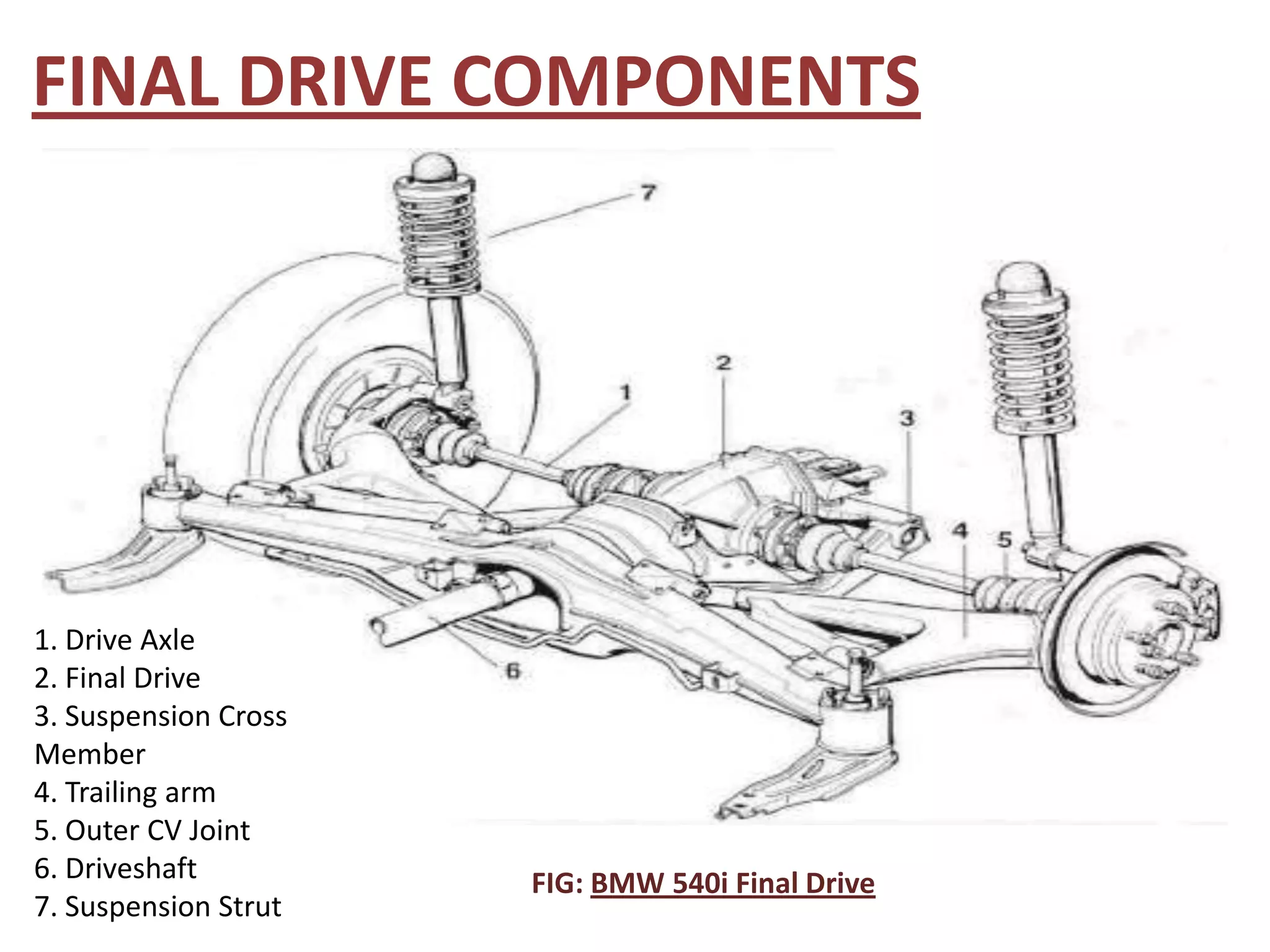

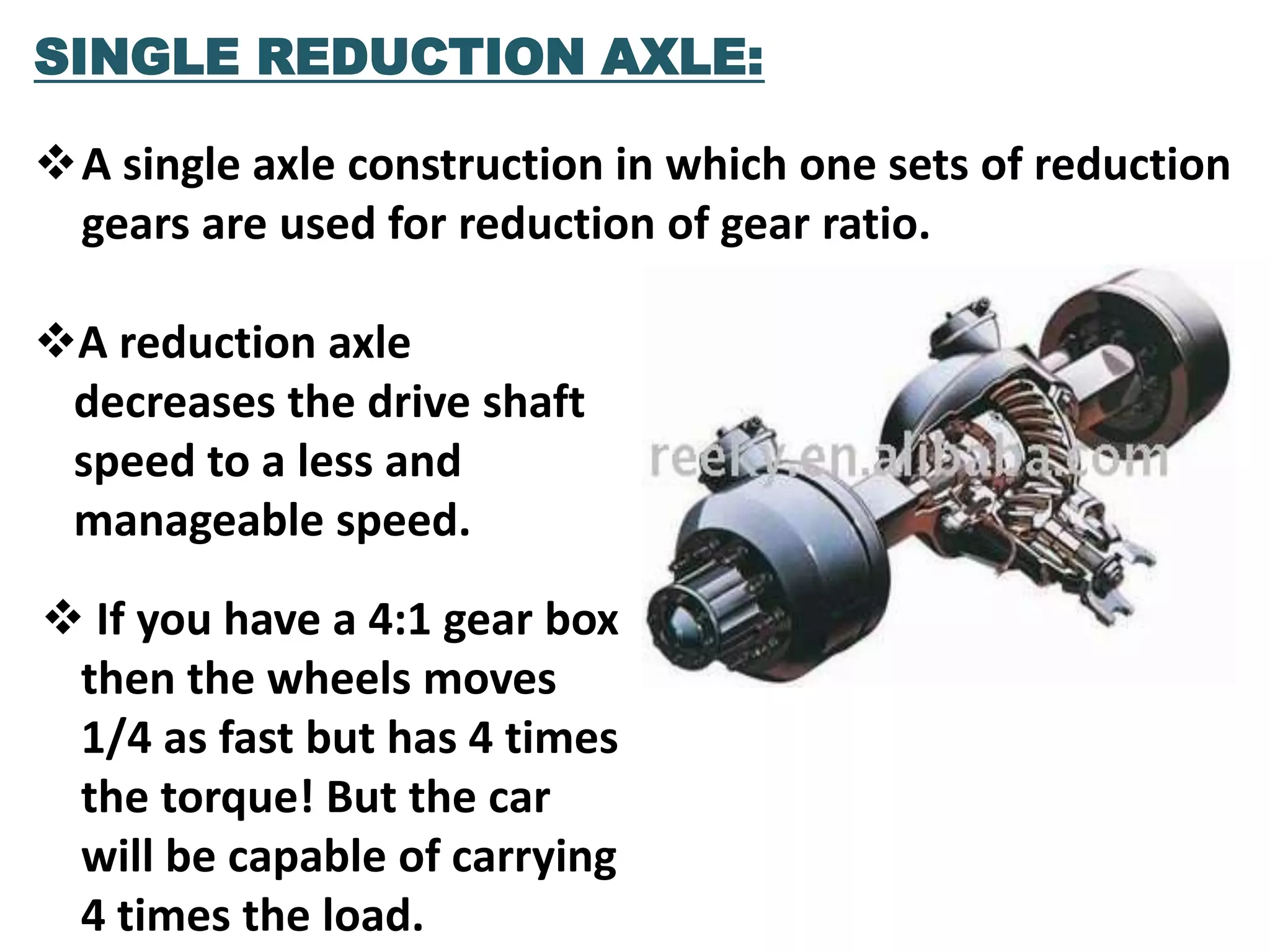

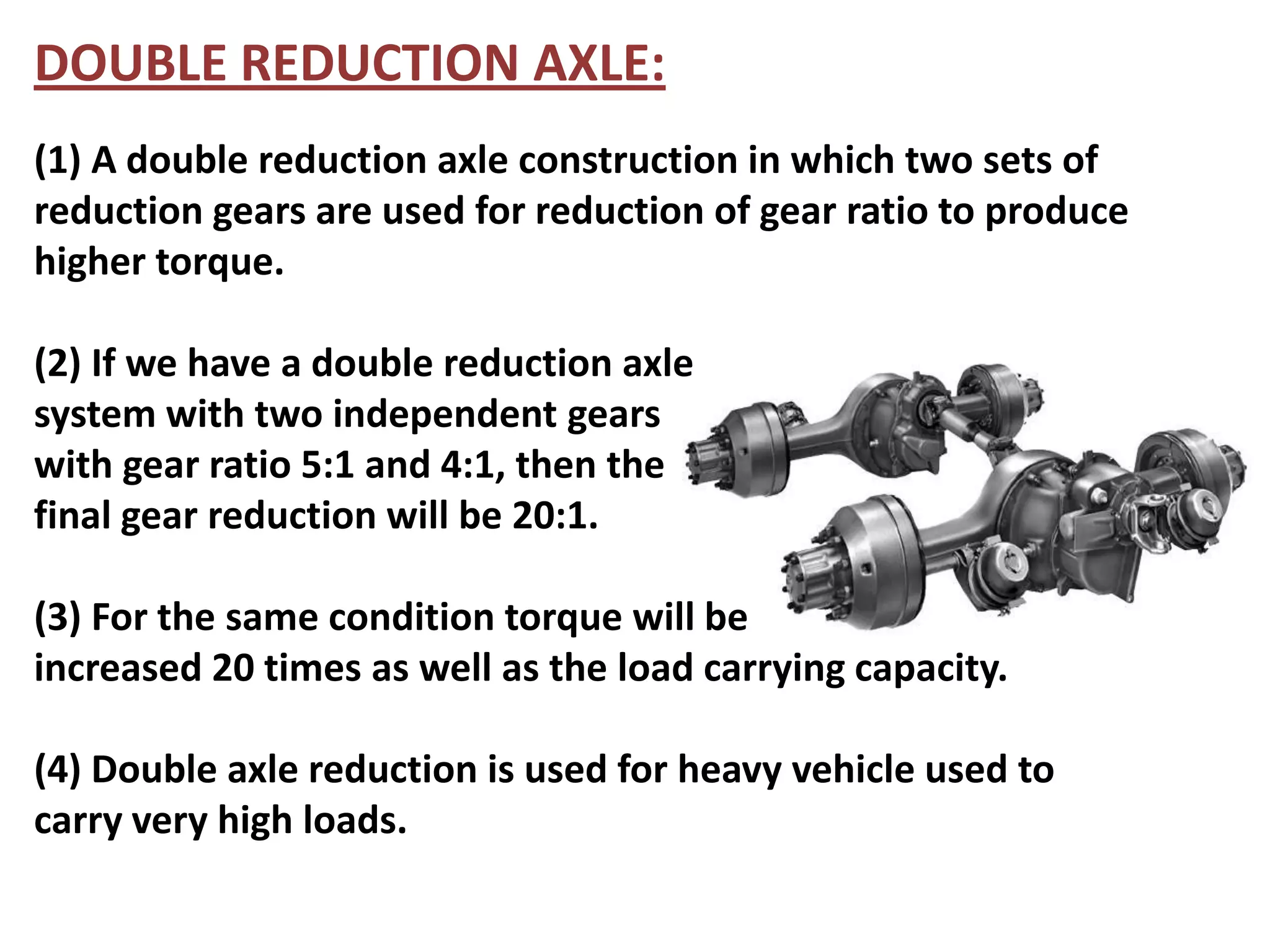

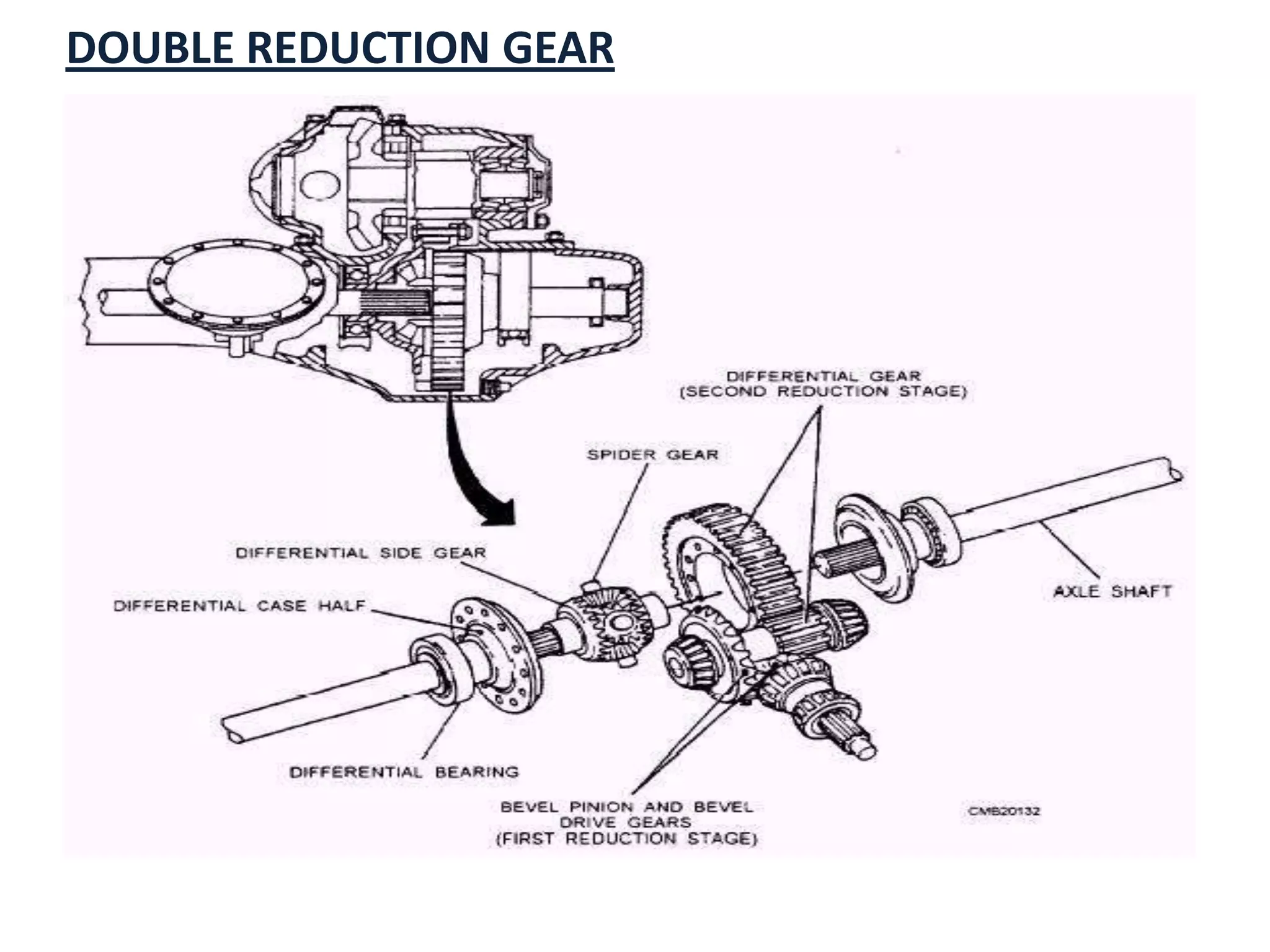

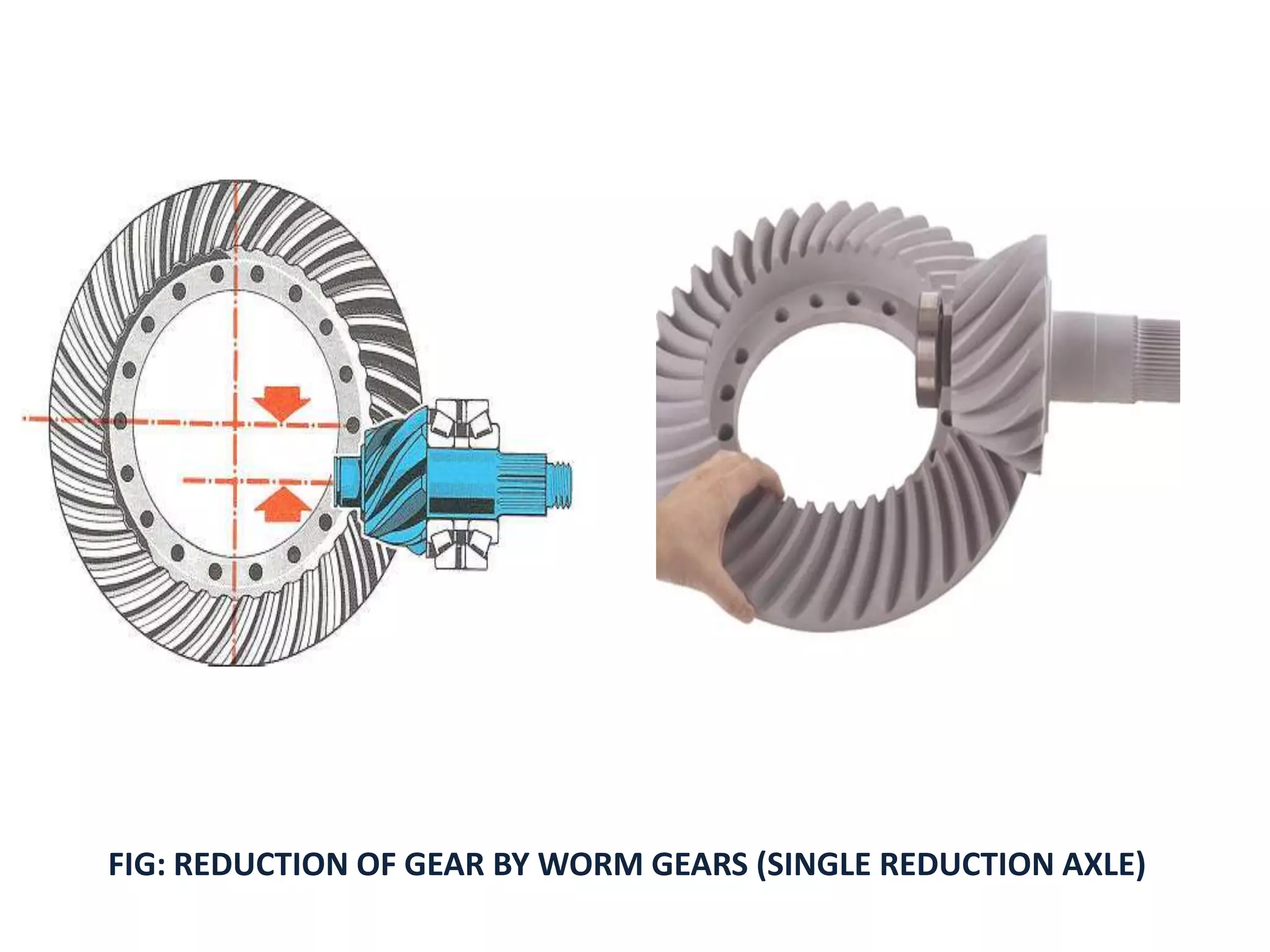

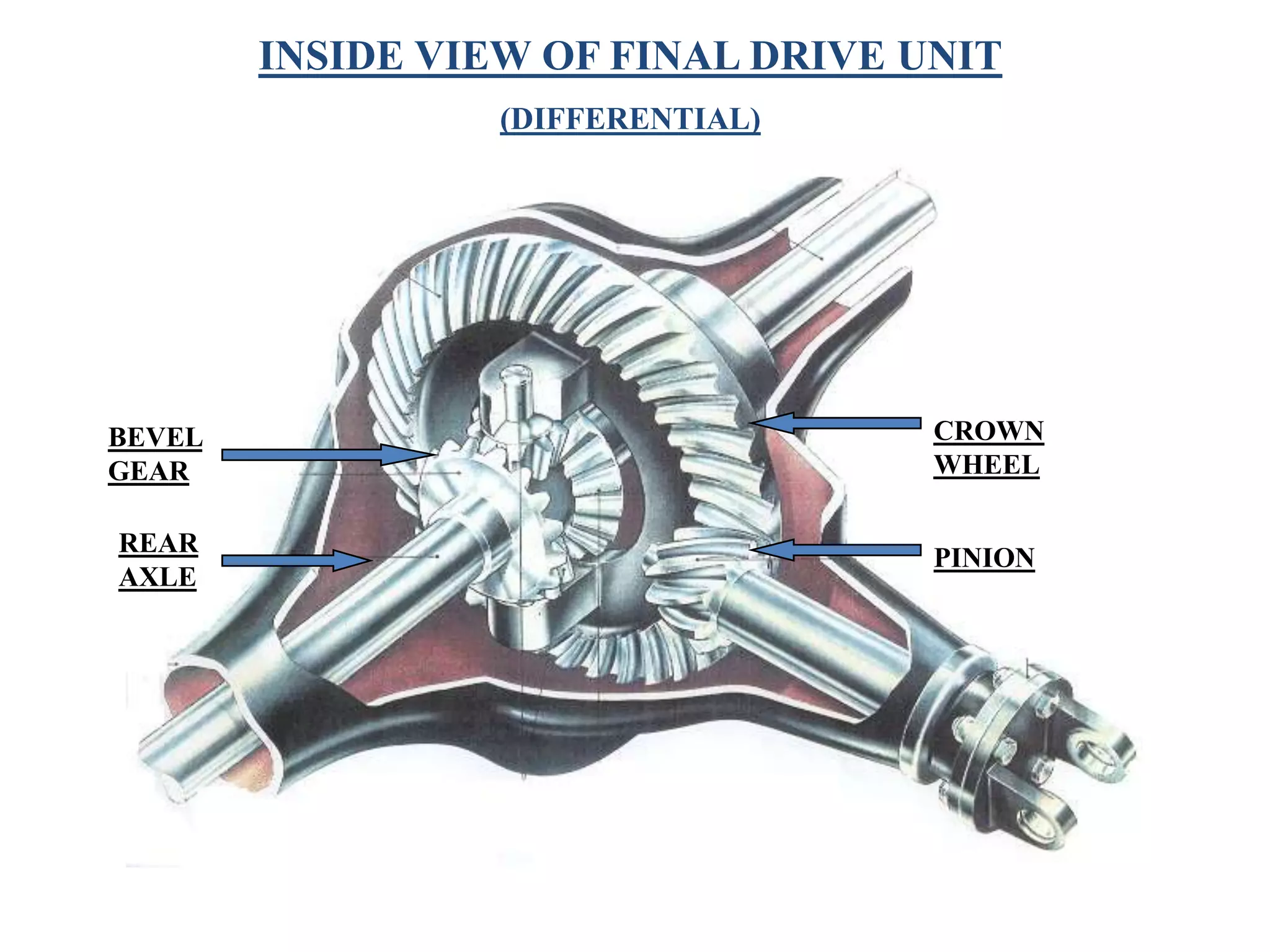

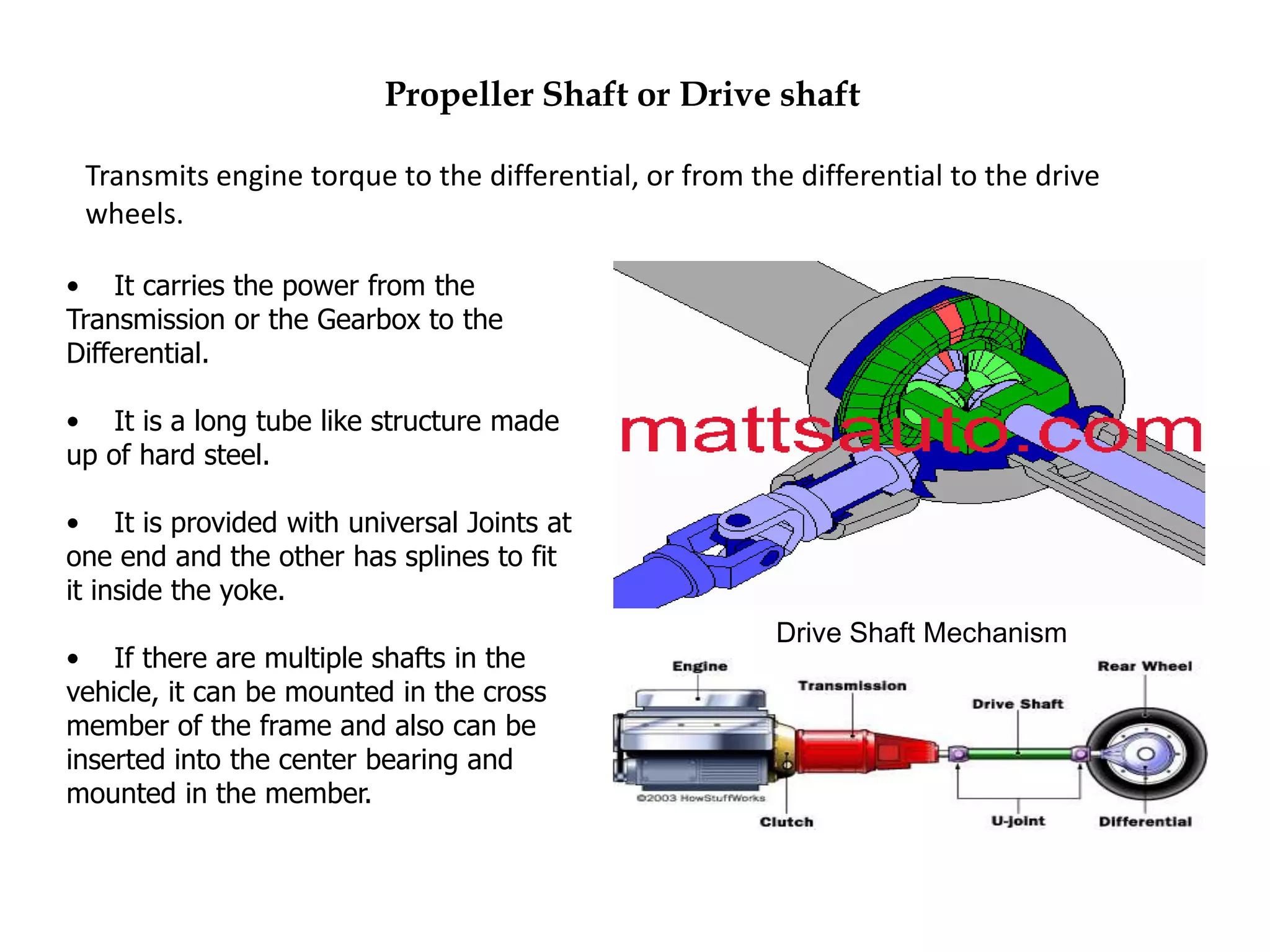

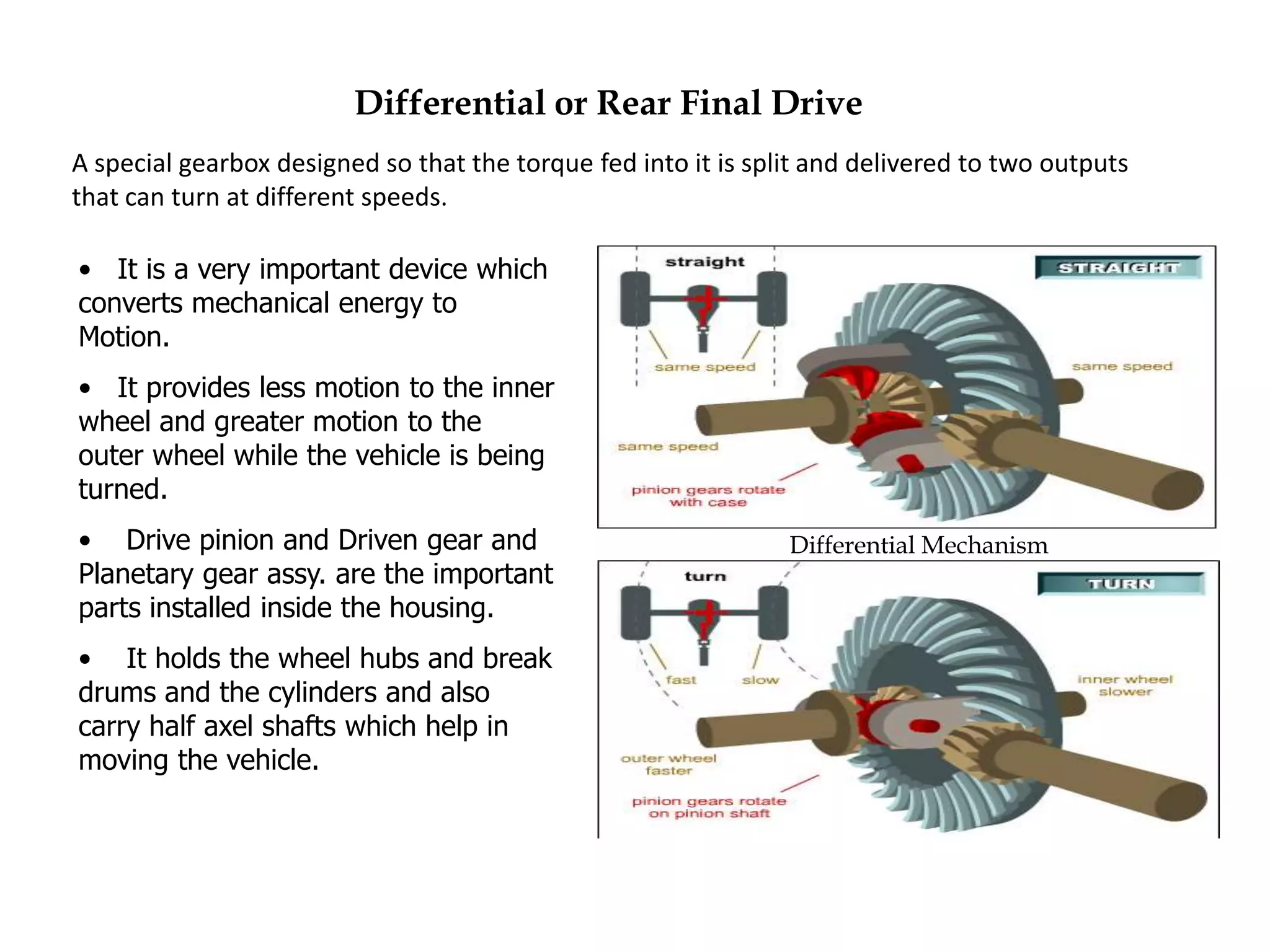

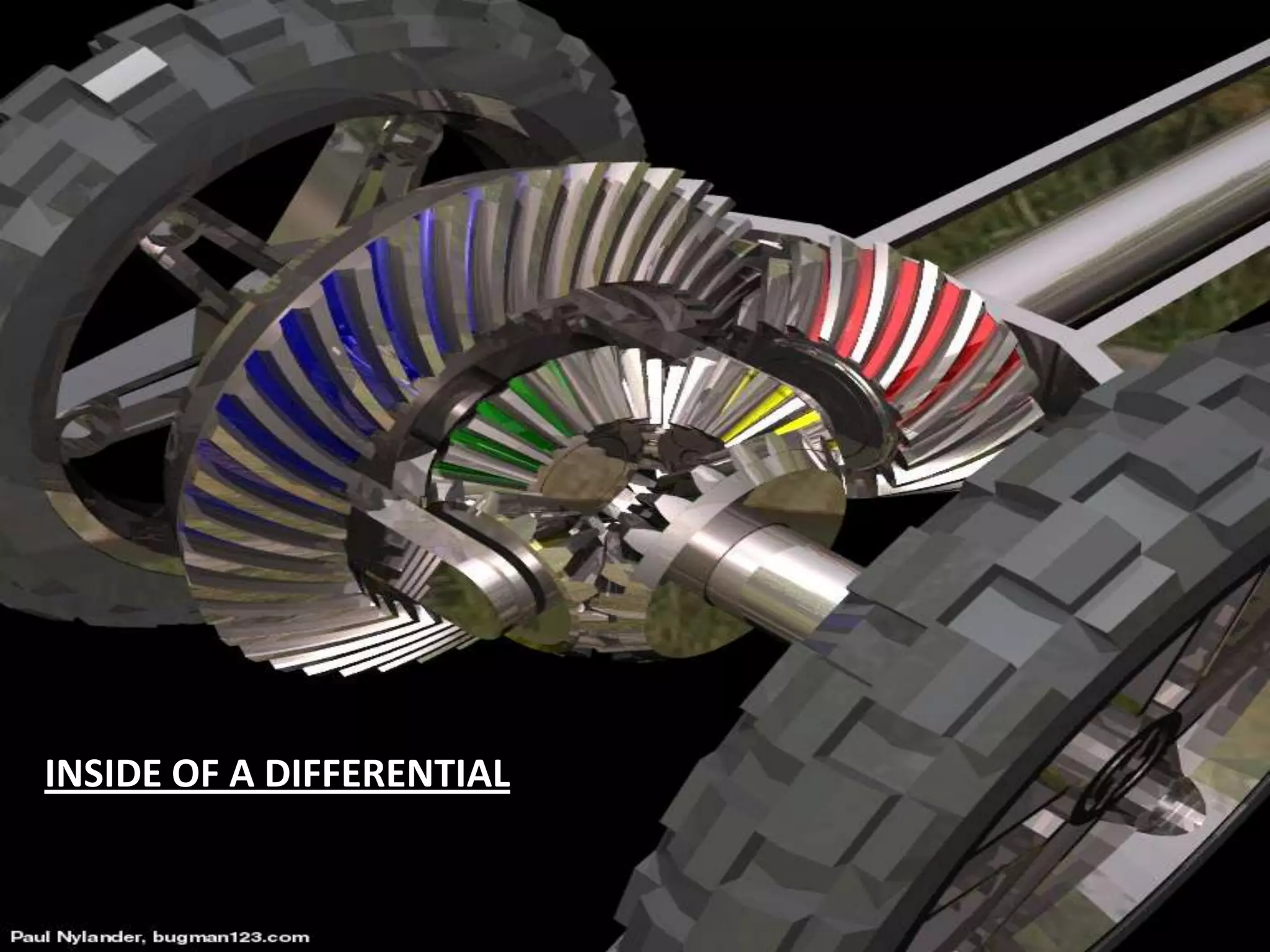

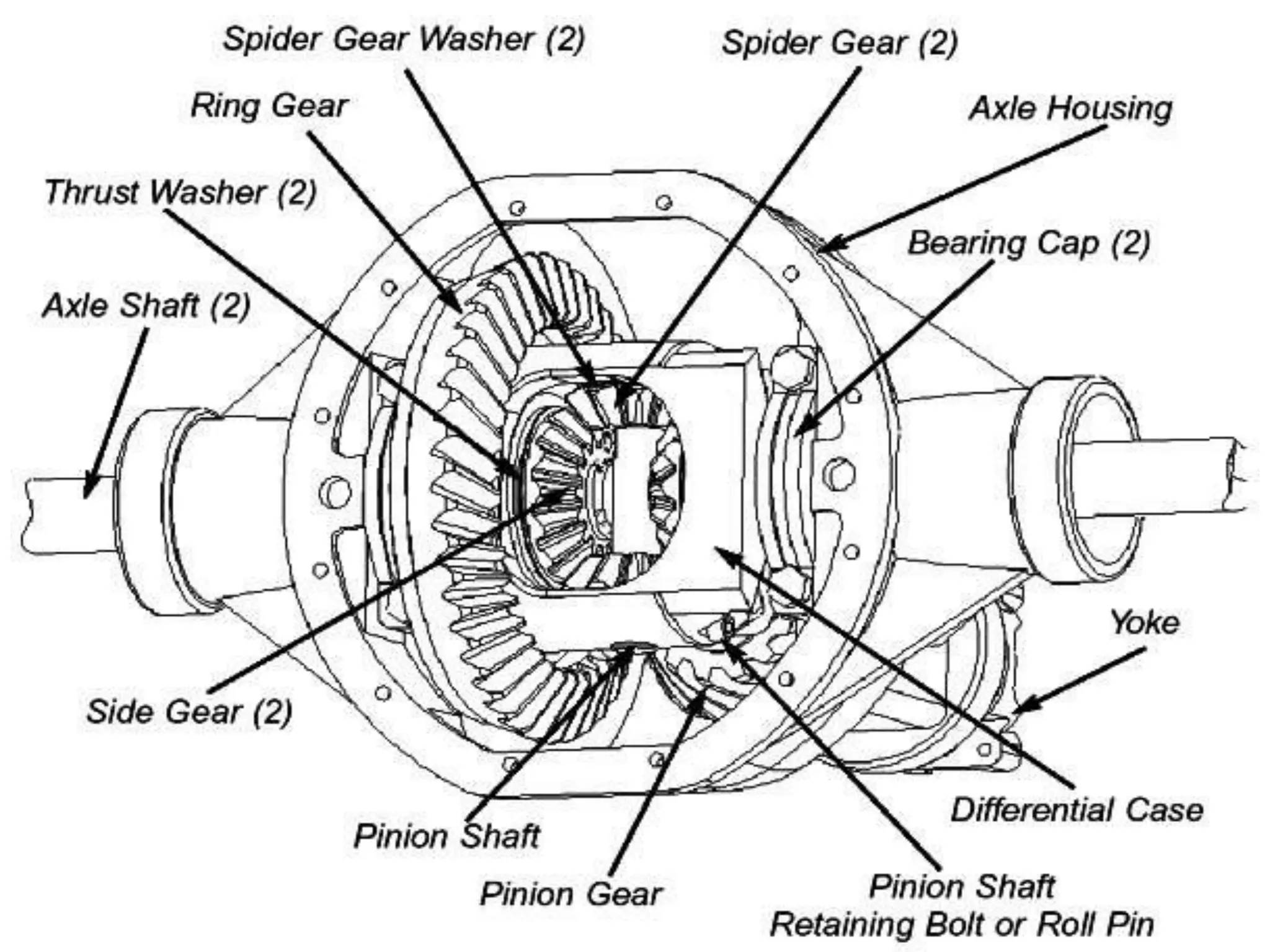

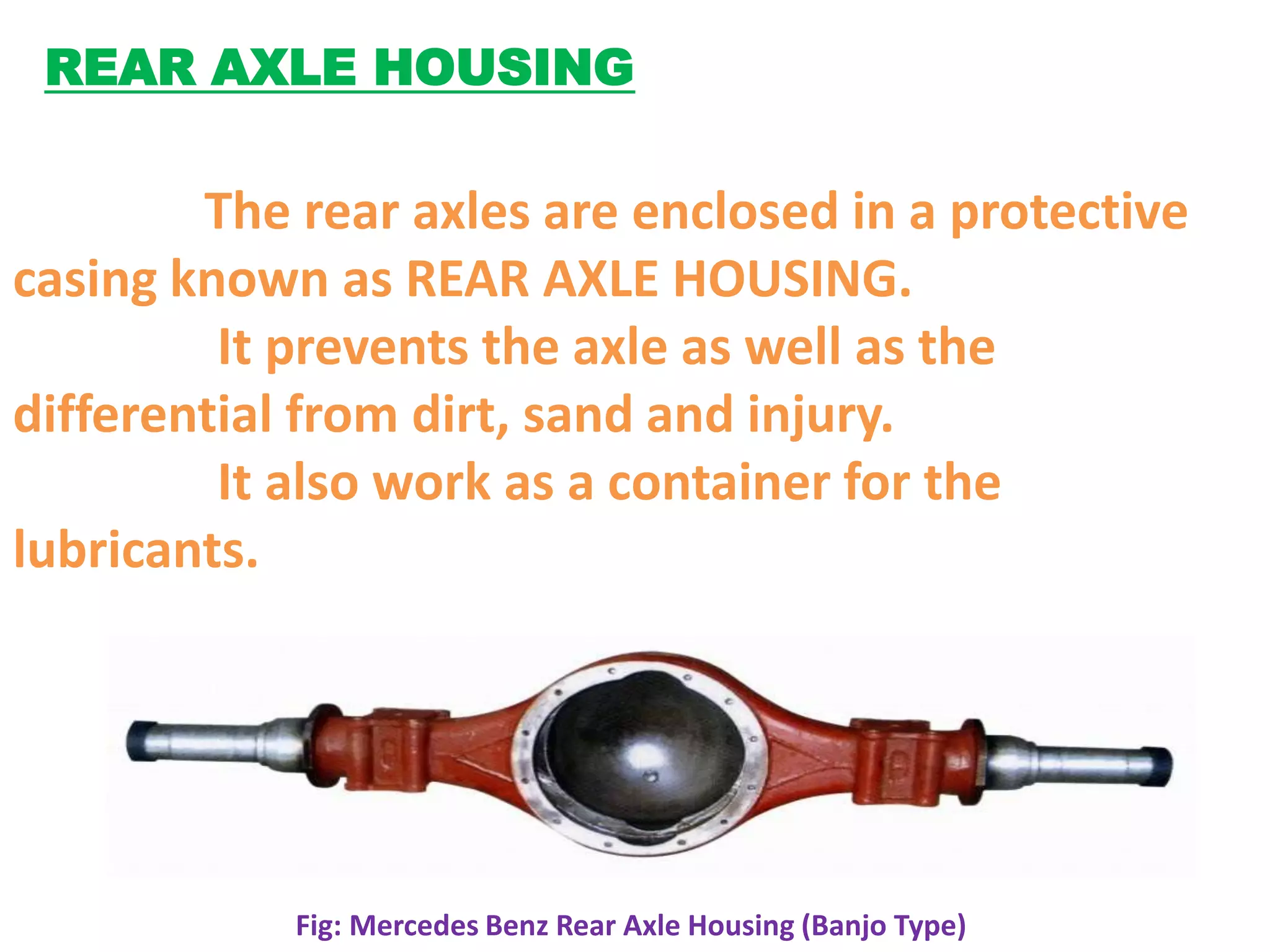

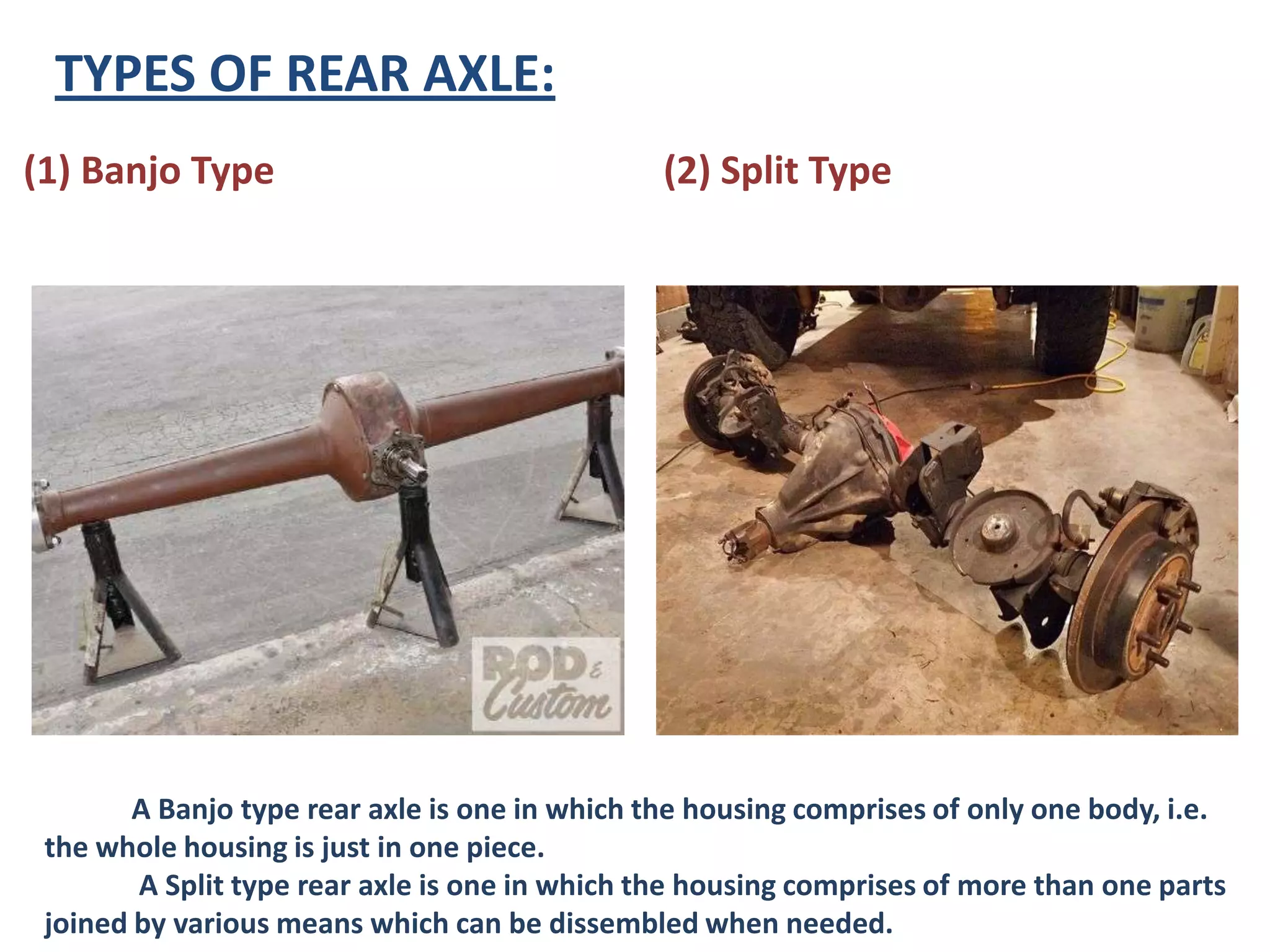

The document discusses the components and functions of a rear axle system in a vehicle. It describes the rear axle as transmitting torque from the propeller shaft or gearbox to the wheels. The key components it outlines are the rear axle housing, tubes for axle shafts, differential, axle shafts, wheel brakes and suspension connection. It then explains functions like changing rotation direction, providing speed reduction and differential action to allow different wheel speeds when turning.