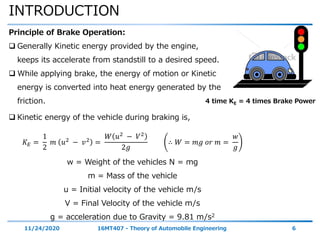

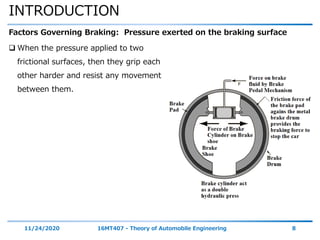

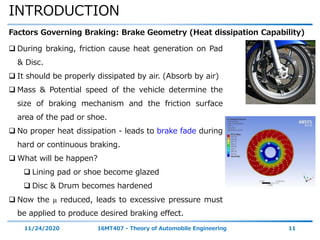

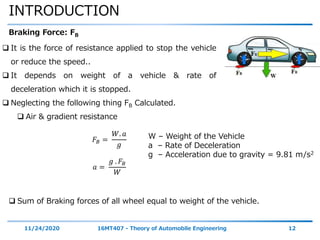

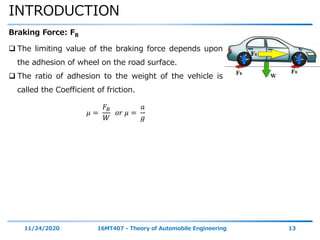

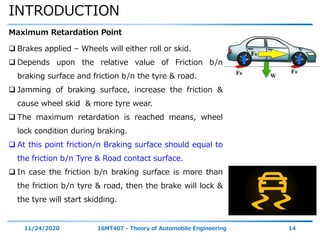

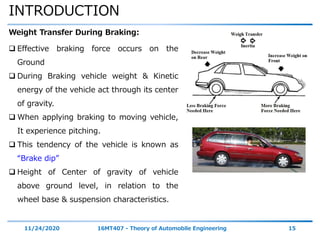

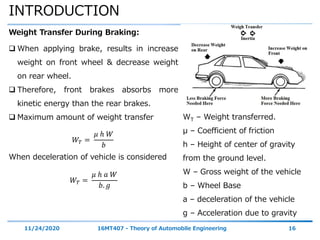

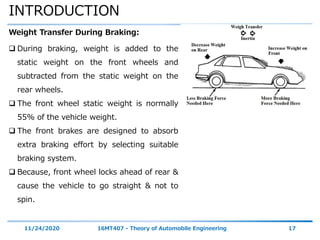

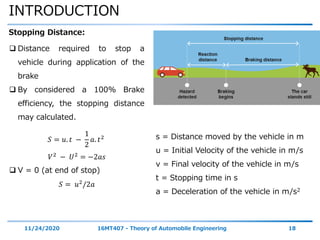

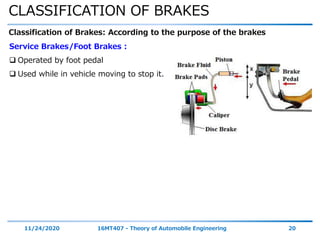

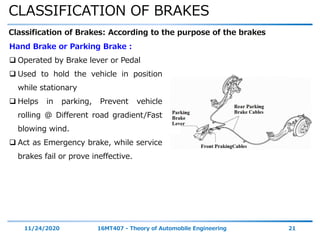

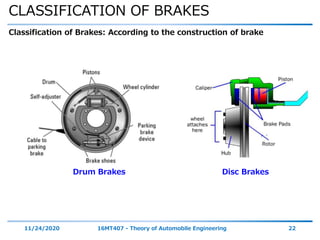

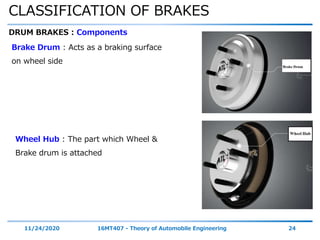

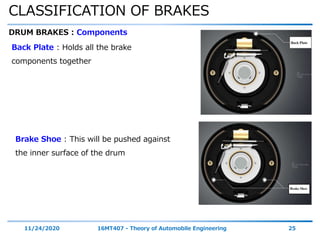

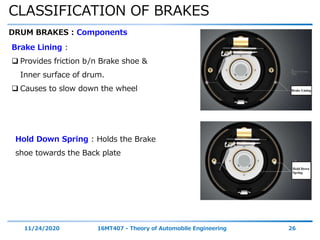

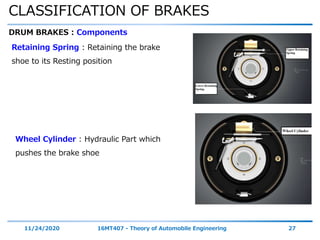

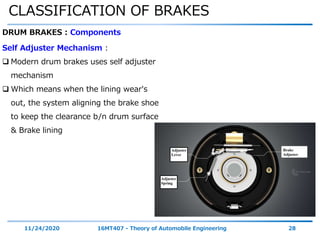

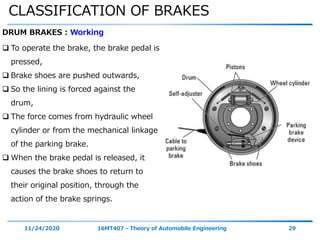

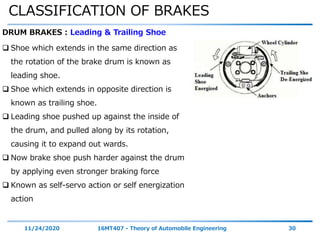

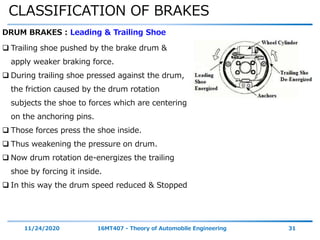

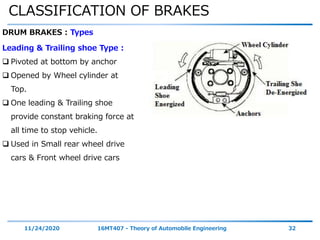

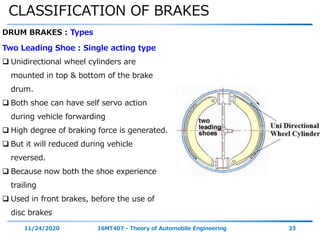

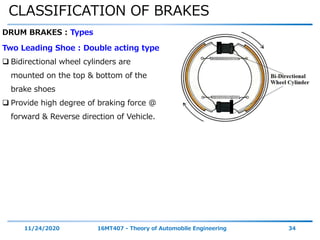

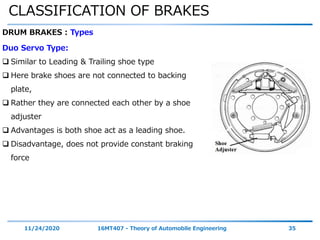

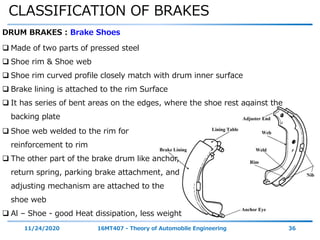

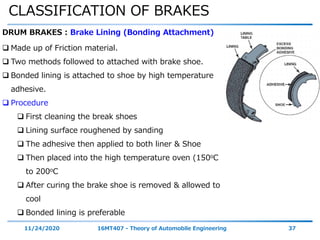

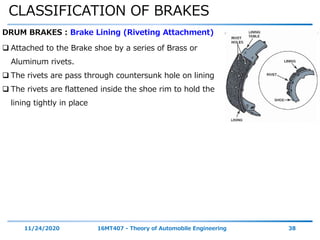

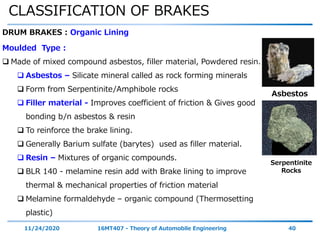

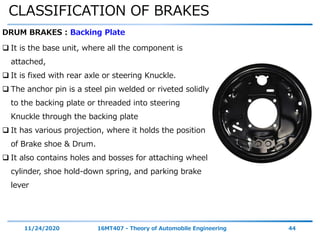

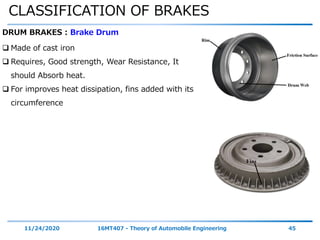

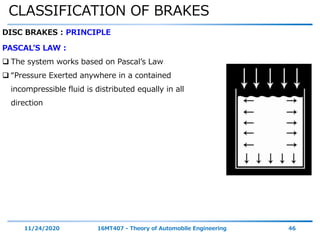

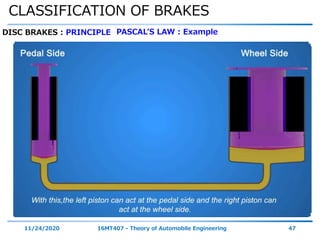

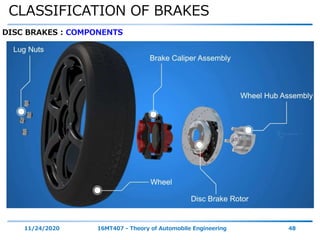

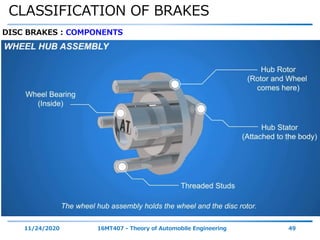

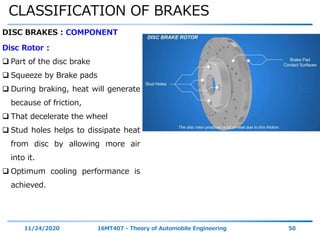

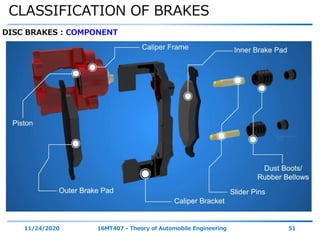

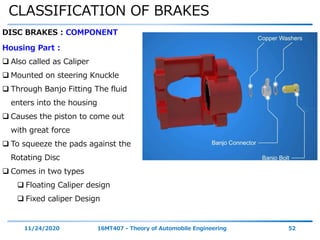

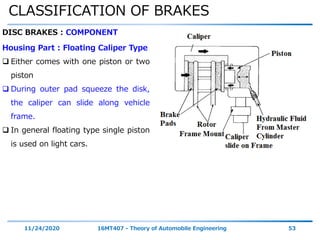

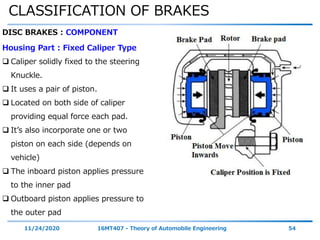

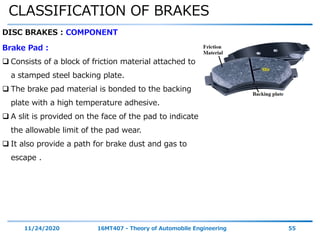

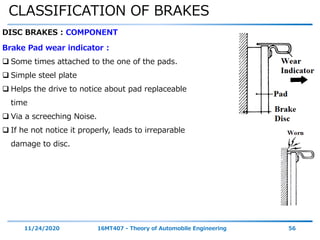

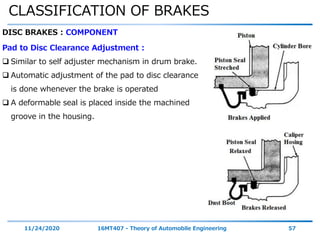

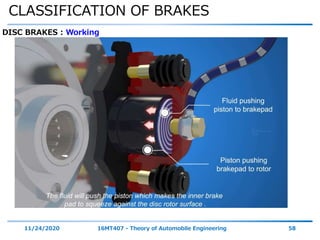

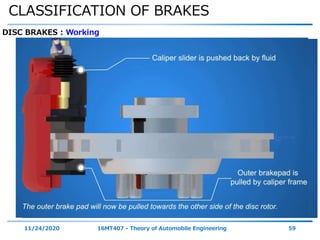

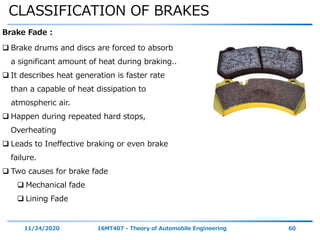

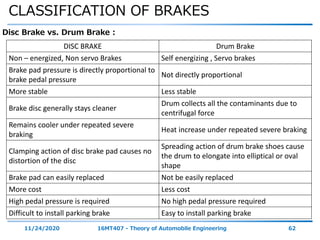

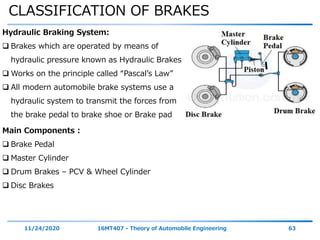

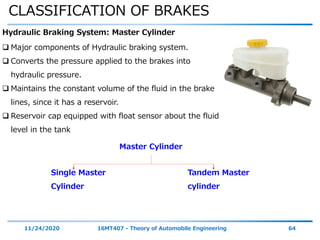

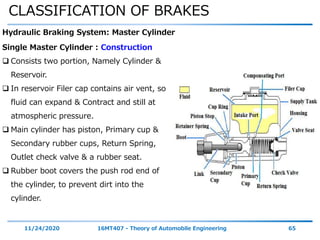

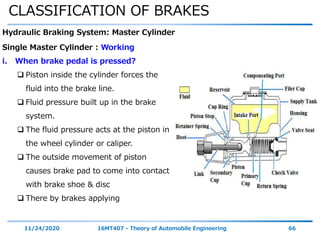

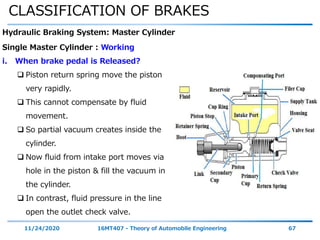

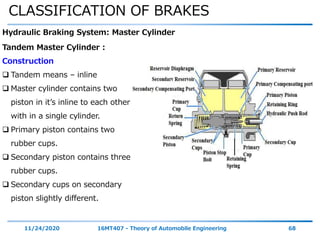

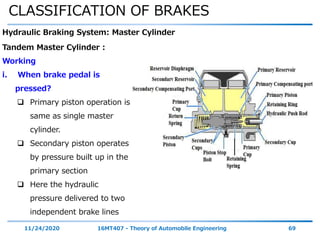

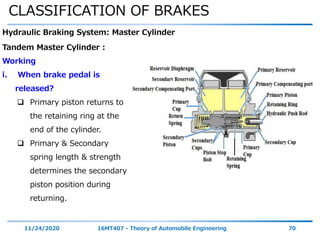

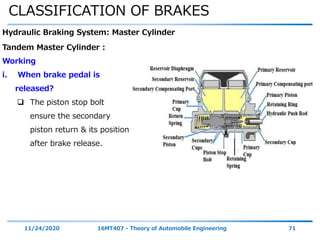

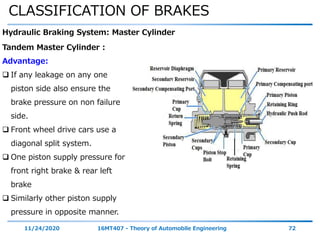

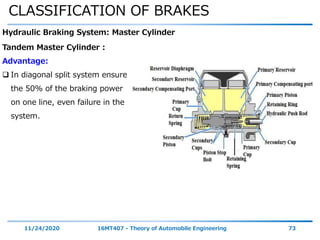

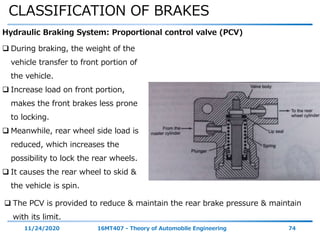

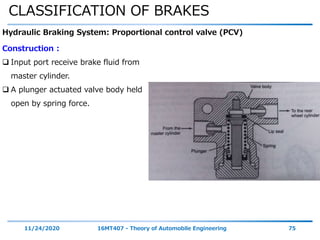

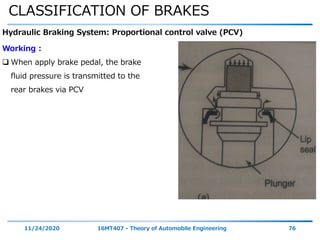

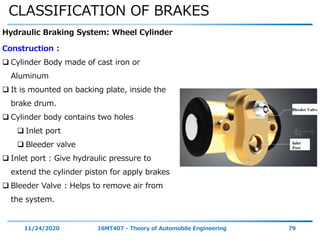

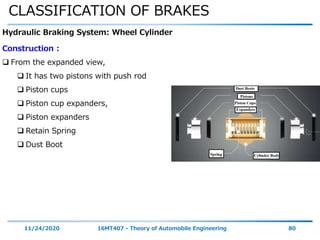

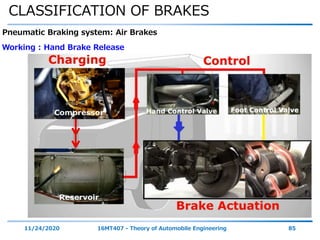

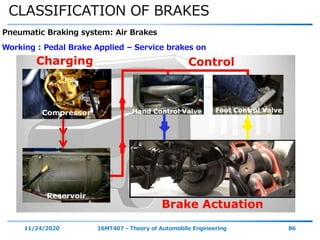

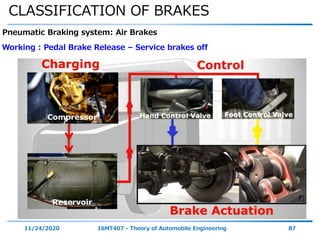

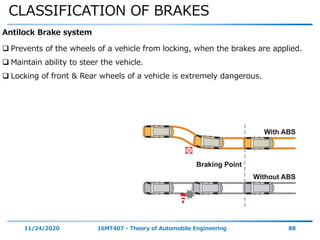

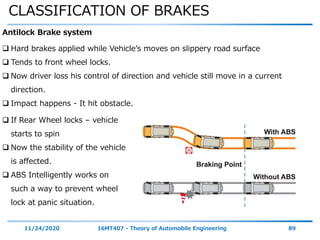

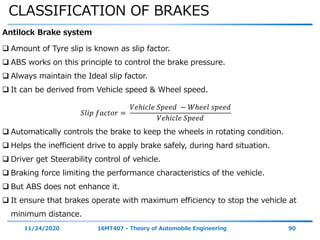

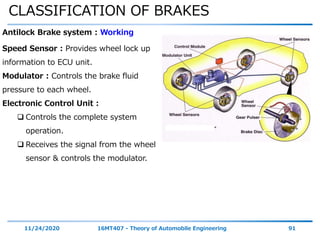

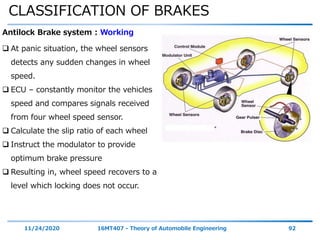

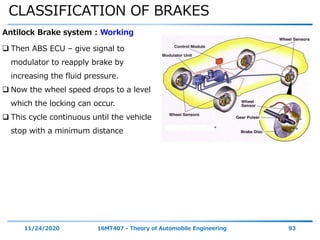

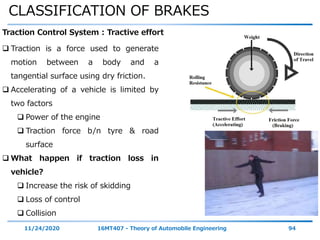

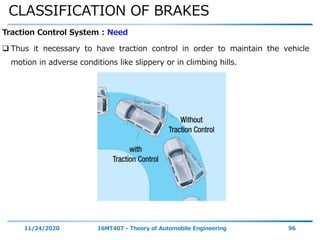

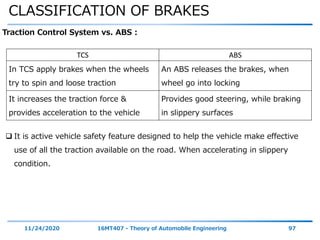

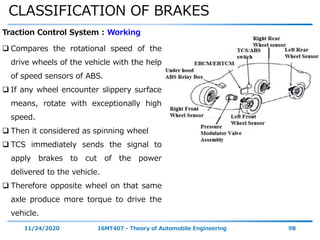

The document discusses vehicle braking systems. It begins with session objectives on understanding proper braking system selection, braking material selection for efficiency, and the role of electronics in ABS and traction control systems. It then covers topics like introduction, brake classification, ABS, and traction control systems. The introduction section defines brakes and their functions, and discusses braking principles, factors like pressure, friction, surface area, geometry. It also covers braking force calculation, weight transfer during braking, and stopping distance calculation. Drum and disc brake components and types are described. [END SUMMARY]