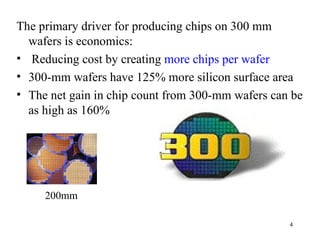

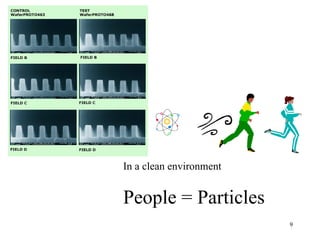

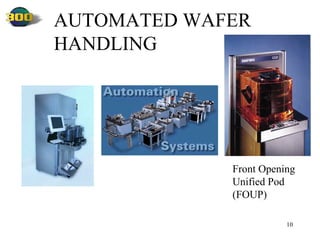

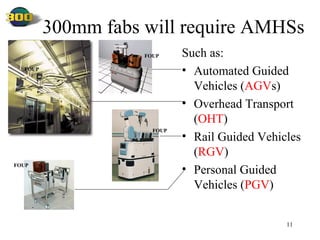

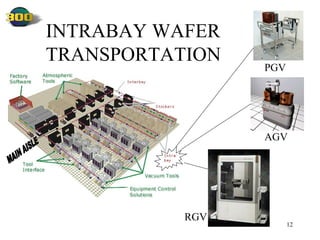

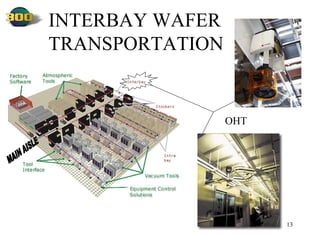

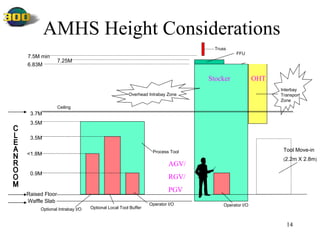

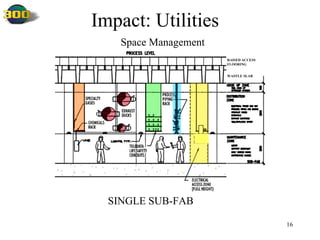

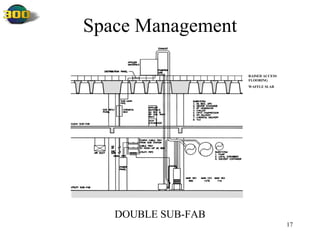

Transitioning from 200mm to 300mm wafer production presents several challenges. 300mm wafers are more expensive and produce more chips, providing economic benefits but requiring larger tool footprints and automated material handling systems. Adopting minienvironments and AMHS aids contamination control as larger wafers are more vulnerable, and manual handling cannot meet high production needs. Facility design must account for increased space, utility and infrastructure requirements of the larger wafers and tools.