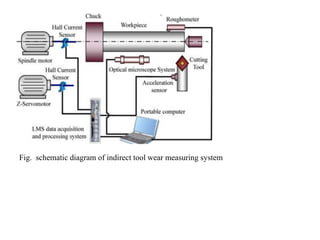

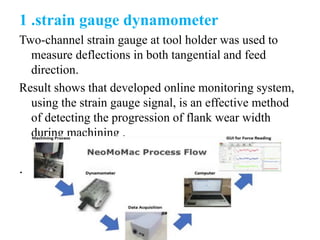

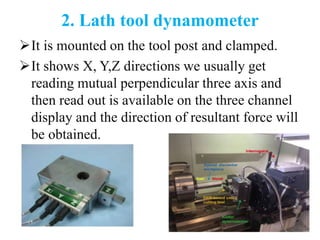

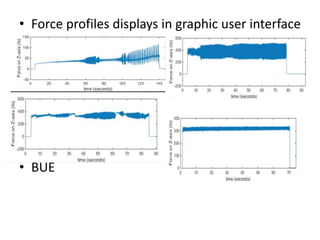

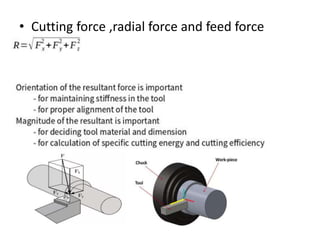

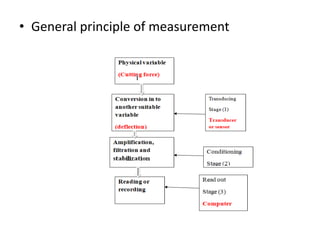

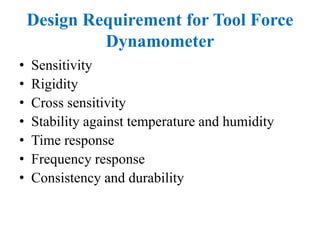

Tool wear measurement is essential in machining as it affects tool life, dimensional accuracy, and surface quality. Effective monitoring can prevent production delays and scrap by predicting tool wear through direct and indirect measurement methods, with cutting force serving as a significant indicator. Various sensors are used in indirect methods to analyze parameters like cutting force, vibration, and temperature to estimate tool condition.