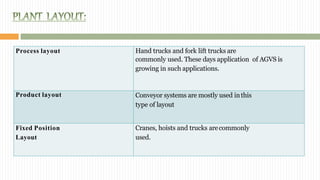

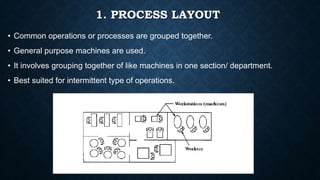

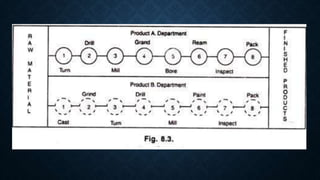

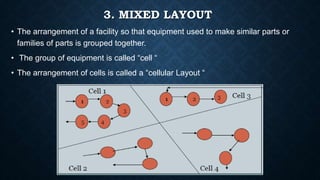

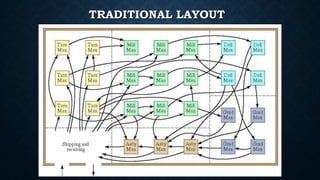

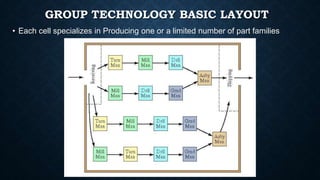

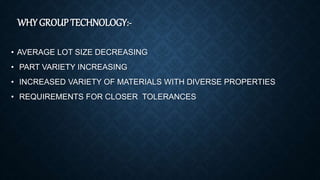

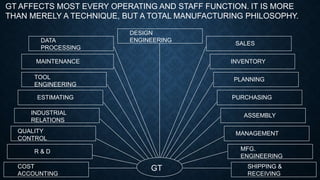

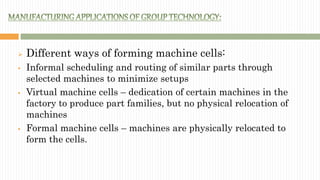

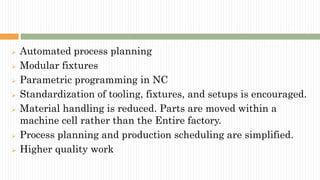

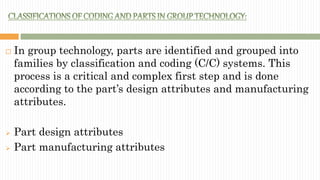

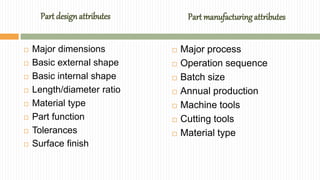

Plant layout refers to the physical arrangement of equipment, machinery, workstations, and space in a manufacturing facility. The key types of layouts discussed are process layout, product layout, mixed layout, fixed layout, and group technology layout. Process layout groups similar processes together while product layout arranges machinery in a linear flow. Group technology layout clusters machines by part families to reduce setup times and material handling. Flexible manufacturing systems apply group technology and automation to allow production of different product styles simultaneously on the same system.