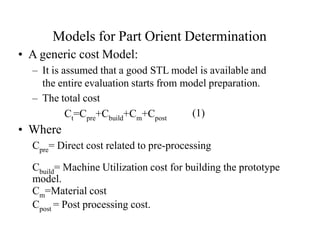

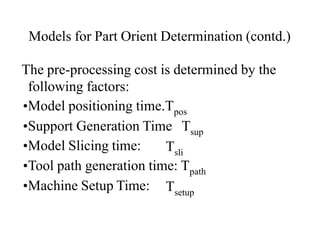

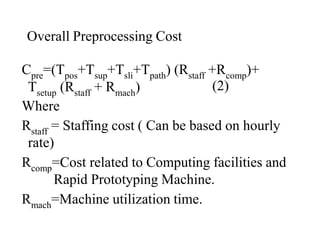

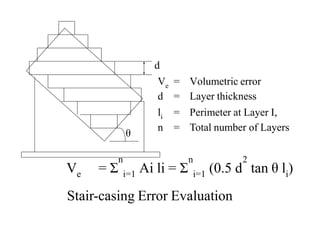

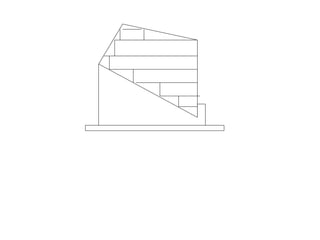

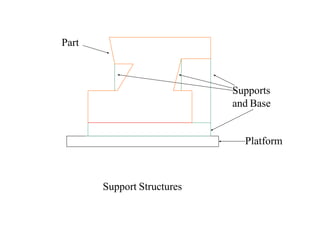

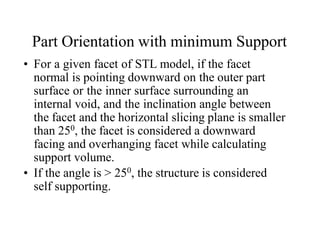

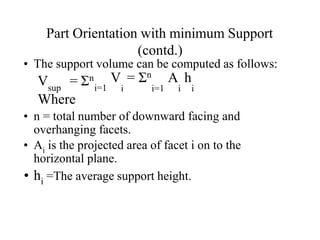

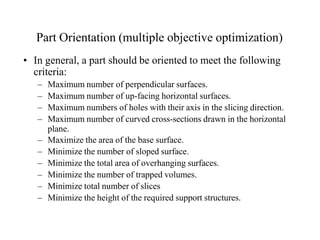

This document discusses factors that affect part orientation for 3D printing, including minimizing build time, support material usage, and improving surface quality. Key factors discussed include orienting parts to reduce the number of overhanging surfaces requiring support, minimizing support volume and contact area to reduce post-processing, and balancing build time and layer thickness to optimize surface finish versus cost. The document also provides models for calculating the total cost of 3D printing based on factors like preprocessing, build time, materials and post-processing.