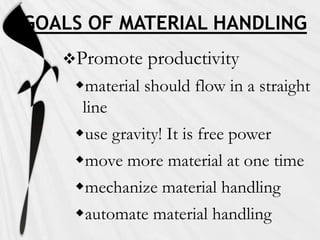

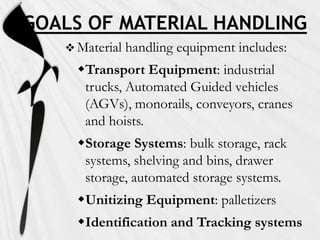

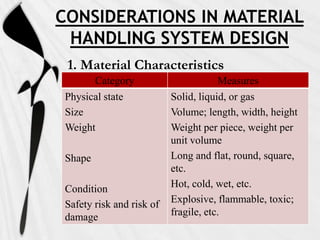

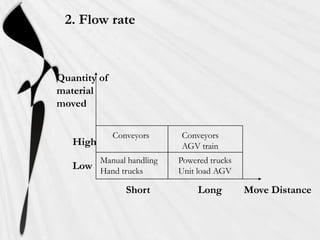

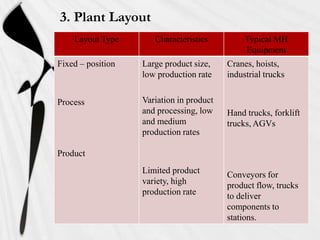

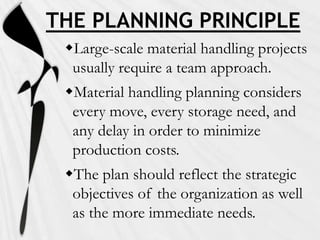

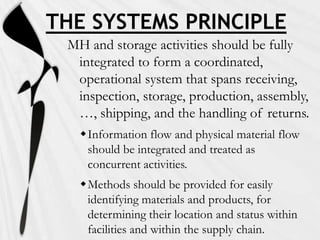

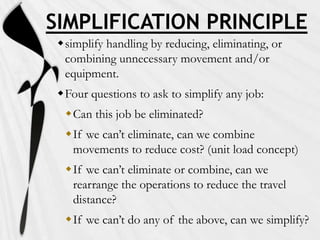

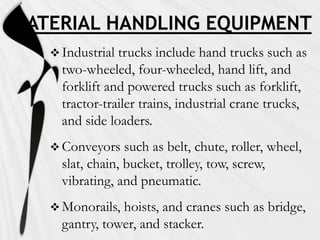

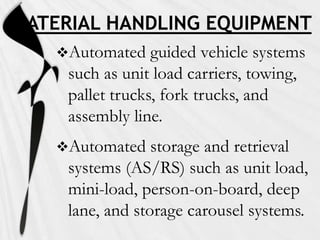

The document discusses material handling, which involves moving materials efficiently through the production process. It defines material handling and lists its goals as reducing costs, maintaining quality, and promoting safety, productivity and facility usage. The document outlines principles for effective material handling system design, such as considering material characteristics, plant layout, simplification, use of gravity, standardization, and maintenance. It also discusses various material handling equipment options.