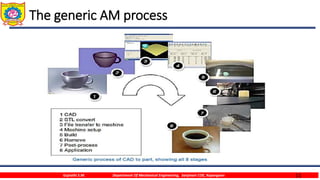

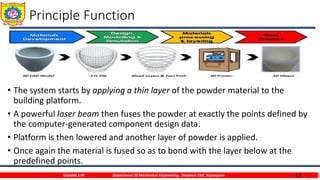

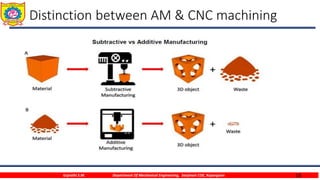

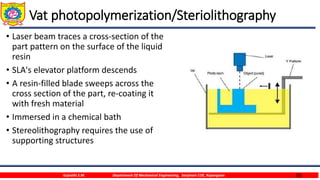

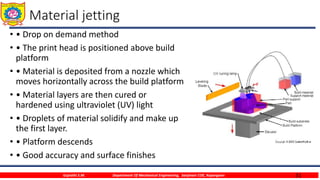

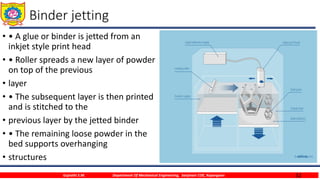

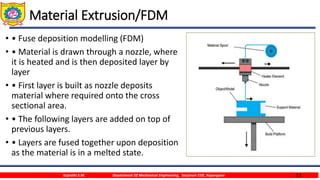

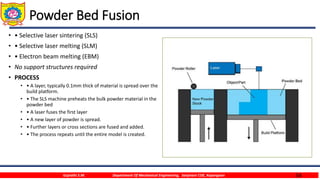

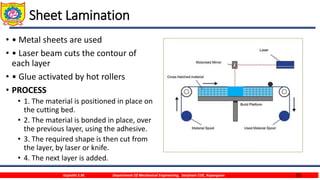

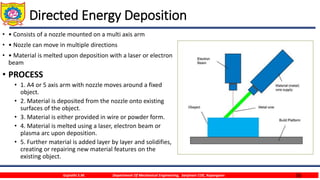

The document discusses additive manufacturing, formerly known as rapid prototyping, highlighting its definition, processes, advantages, disadvantages, and applications across various industries. It covers essential concepts such as the transition from CAD models to 3D printed objects, along with different methods like photopolymerization, material extrusion, and powder bed fusion. The text also addresses the limitations and steps involved in the additive manufacturing process, providing insights into its potential and the challenges it faces.