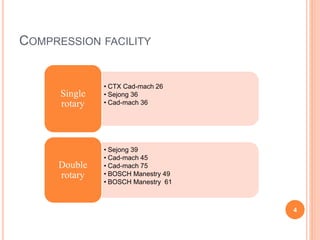

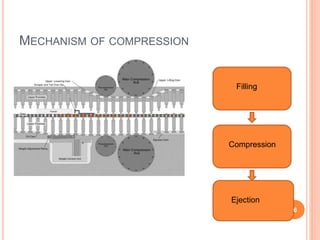

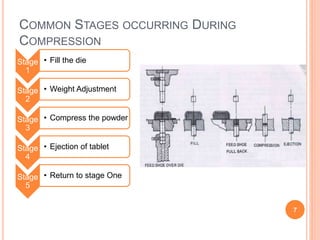

The document discusses the working principle of compression machines used in pharmaceutical manufacturing. It describes the main components of compression machines including hoppers, dies, punches, and cam tracks. It explains the compression cycle which involves filling the die, weight adjustment, compressing the powder, and ejecting the tablet. Key process parameters that affect tablet quality such as filling depth, compression force, and turret speed are also summarized.