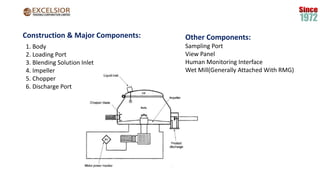

The document presents an overview of the Gansons High Shear Mixer Granulator (HSRMG), detailing its construction, components, and operational benefits in solid dose production, including uniform mixing and granulation technology. It emphasizes Gansons' patented design, scalability across different production scales, and market competitiveness with references to existing clients. The advantages of Gansons equipment also include energy efficiency, reliability, and strong technical support.